- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

100kg

-

Weight (KG):

-

310 KG

-

Place of Origin:

-

Henan

-

Brand Name:

-

WKS

-

Voltage:

-

110V/220V/380V

-

Dimension(L*W*H):

-

1685*800*1850

-

Power (kW):

-

1.1 kW

-

Marketing Type:

-

Hot Product

-

Function:

-

Mxing Dry Powder

-

Keyword:

-

Industrial Liquid Mixer

-

Usage:

-

Food Industry

-

Application scope:

-

Food Chemical

-

Mixing type:

-

Top Blending

-

Capacity:

-

200L - 5000L Customization

-

Stirrer type:

-

High Speed Homogenizer

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Barrel Volume (L):

-

300

-

Max. Loading Volume (L):

-

180 L

-

Range of Spindle Speed(r.p.m):

-

0 - 12 r.p.m

-

Max. Loading Capacity:

-

100kg

-

Weight (KG):

-

310 KG

-

Place of Origin:

-

Henan

-

Brand Name:

-

WKS

-

Voltage:

-

110V/220V/380V

-

Dimension(L*W*H):

-

1685*800*1850

-

Power (kW):

-

1.1 kW

-

Marketing Type:

-

Hot Product

-

Function:

-

Mxing Dry Powder

-

Keyword:

-

Industrial Liquid Mixer

-

Usage:

-

Food Industry

-

Application scope:

-

Food Chemical

-

Mixing type:

-

Top Blending

-

Capacity:

-

200L - 5000L Customization

-

Stirrer type:

-

High Speed Homogenizer

-

Feature:

-

High Efficiency Low Cost

-

Advantage:

-

Easy Operation High Efficiency

Products Description

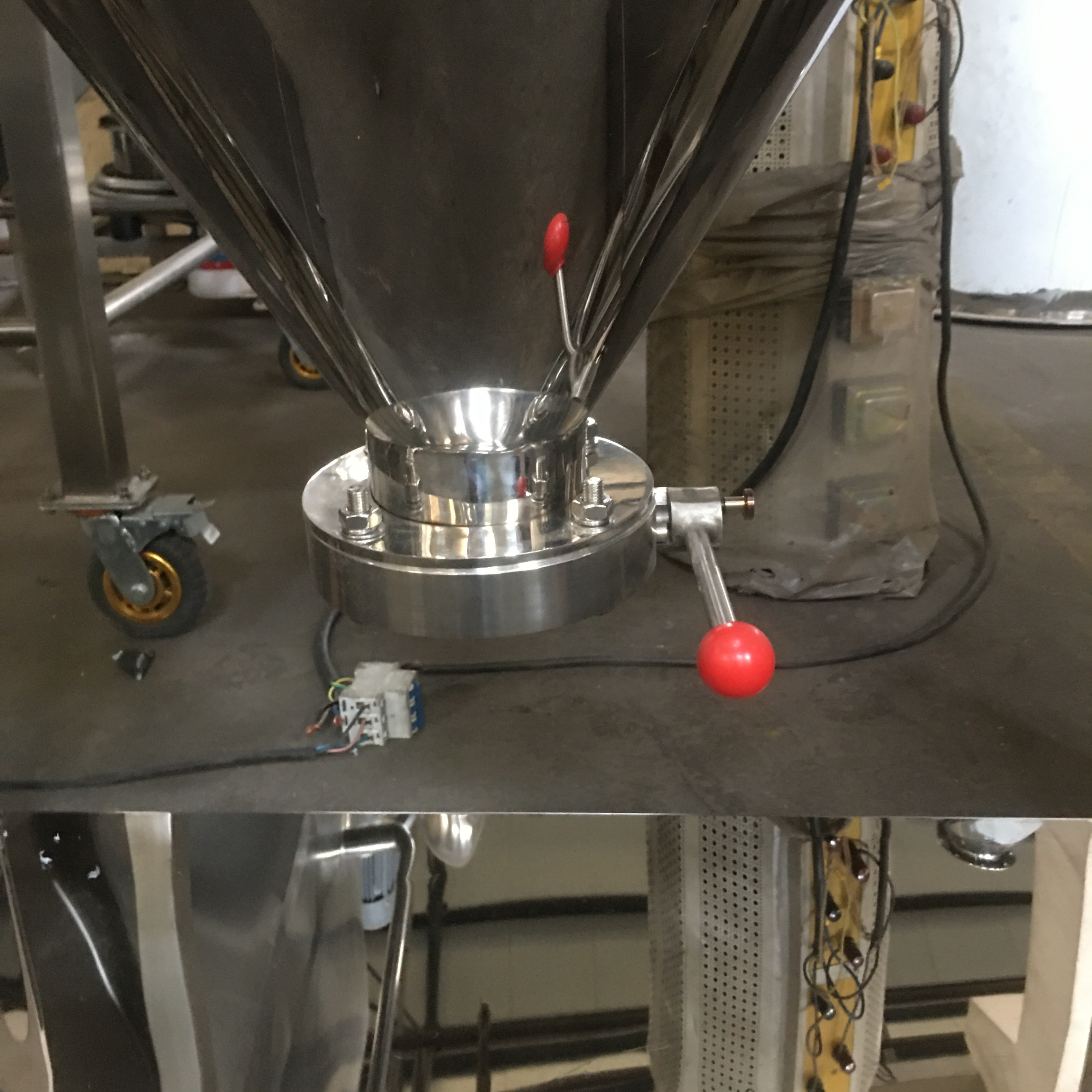

The SZH series Double cone mixer

is mainly used for the uniform mixing of powder and granular materials in the chemical, electronic and food industries.

This machine is mainly composed of mixing barrel, frame, transmission system, electrical system and other parts. It uses two asymmetric barrels and adopts gravity mixing. The materials are continuously gathered and dispersed in the barrel, generally after 10~ It takes about 30 minutes to mix, so that two or more powder and granular materials are fully mixed and uniform, especially suitable.

When the proportion of two or more materials is combined, the mixing uniformity can reach more than 99%. The inner and outer walls of the mixing barrel are precisely polished, and the surface is smooth, flat, without dead ends, and easy to clean. During the working process of the transmission system, there is no jitter, no noise, easy maintenance, accurate and sensitive electrical control, and stainless steel butterfly valve discharge, no leakage and no dust. The machine is unique in design, beautiful in appearance and versatile in use. It is an ideal equipment for mixing materials.

Product Features

Application

The

SZH series

Double cone mixer refers to a mixing equipment that mixes various powders evenly through a rotating tank. It is widely used in spices, chemicals, food, feed, fuel, electronics and other industries. This machine can mix powders and granules with good fluidity, and the effect is remarkable. All technical indicators can reach the standards of similar foreign products.

FAQ

Q: What is the information should be provided in order to get a proposal or quotation?

A: We provide customized production services for customer, in order to get a professional quotation please provide the following information:

1) Raw material particle size.

2) Raw material bulk density.

3) Mixing capacity per batch

4) Machine material requirements.

Q: What is the lead time?

A:15-20 working days.

Q: How the machine will be delivered ?

A: The mixer is packed in wooden case for shippment.

Q: What is the standard models do you have?

A: We have the following standard models

Product Parameters

|

Model

|

Volume (L)

|

Capacity

(kg)

|

Mixing time

(min)

|

Speed

(rpm)

|

Power

(kw)

|

Dimensions

(mm)

|

Rotaty height

(mm)

|

Weight

(kg)

|

|

SZH-100

|

100

|

50

|

4-8

|

12

|

0.75

|

1400*540*1850

|

1850

|

200

|

|

SZH-180

|

180

|

90

|

4-8

|

12

|

1.1

|

1400*800*1850

|

1850

|

280

|

|

SZH-300

|

300

|

150

|

6-10

|

12

|

1.1

|

1685*800*1850

|

1850

|

310

|

|

SZH-500

|

500

|

250

|

6-10

|

12

|

2.2

|

1910*800*1940

|

1950

|

550

|

|

SZH-1000

|

1000

|

500

|

6-10

|

12

|

3

|

2765*1500*2370

|

2460

|

810

|

|

SZH-1500

|

1500

|

750

|

6-10

|

10

|

4

|

2960*1500*2480

|

2540

|

980

|

|

SZH-2000

|

2000

|

1000

|

6-10

|

7-10

|

5.5

|

3160*1900*3500

|

3590

|

1500

|

|

SZH-2500

|

2500

|

1250

|

6-10

|

10

|

7.5

|

3386*1900*3560

|

3650

|

2150

|

|

SZH-3000

|

3000

|

15000

|

6-10

|

7-8

|

7.5

|

4450*2200*3600

|

3700

|

2500

|

|

SZH-4000

|

4000

|

2000

|

6-10

|

7-8

|

11

|

4750*2500*3680

|

3730

|

3200

|

Packing & Shipping

Hot Searches