- Product Details

- {{item.text}}

Quick Details

-

Knitting Method:

-

three system

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 3 GG, 7 GG, 12 GG, 14 GG, 2 GG, 16 GG, 9 GG, 5 GG, 10GG, 2.5GG, 8GG, 3-5-7 multi-gauge, 8-10-12 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HAOYUE

-

Power:

-

1700 W

-

Weight:

-

1100 KG

-

Dimension(L*W*H):

-

2800*900*1800mm

-

Product Name:

-

sweater knitting machine

-

guage:

-

3G, 5G, 7G, 8G, 9G, 10G, 12G, 14G, 16G

-

knitting width:

-

52Inch

-

knitting system:

-

three system

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Free spare parts

-

Certificate:

-

CE Certificate

Quick Details

-

Type:

-

Flat

-

Production Capacity:

-

1.6m/s

-

Knitting Style:

-

Weft

-

Knitting Method:

-

three system

-

Computerized:

-

Yes

-

Gauge:

-

1.5 GG, 3 GG, 7 GG, 12 GG, 14 GG, 2 GG, 16 GG, 9 GG, 5 GG, 10GG, 2.5GG, 8GG, 3-5-7 multi-gauge, 8-10-12 multi-gauge

-

Knitting width:

-

52 inch

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HAOYUE

-

Power:

-

1700 W

-

Weight:

-

1100 KG

-

Dimension(L*W*H):

-

2800*900*1800mm

-

Product Name:

-

sweater knitting machine

-

guage:

-

3G, 5G, 7G, 8G, 9G, 10G, 12G, 14G, 16G

-

knitting width:

-

52Inch

-

knitting system:

-

three system

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Free spare parts

-

Certificate:

-

CE Certificate

Similar stoll industrial sweater knitting machine sale NINGBO HAOYUE

|

PRODUCT SHOW |

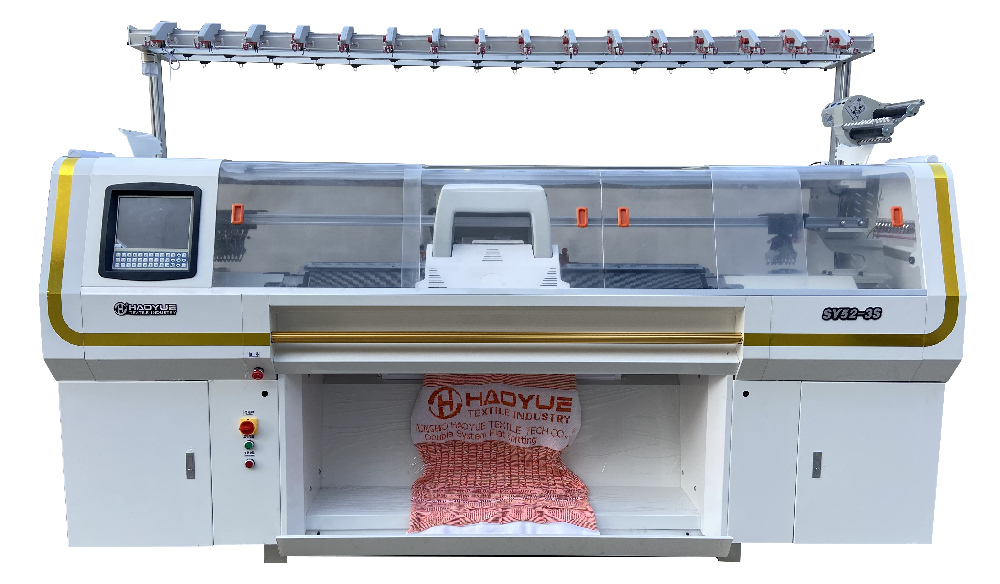

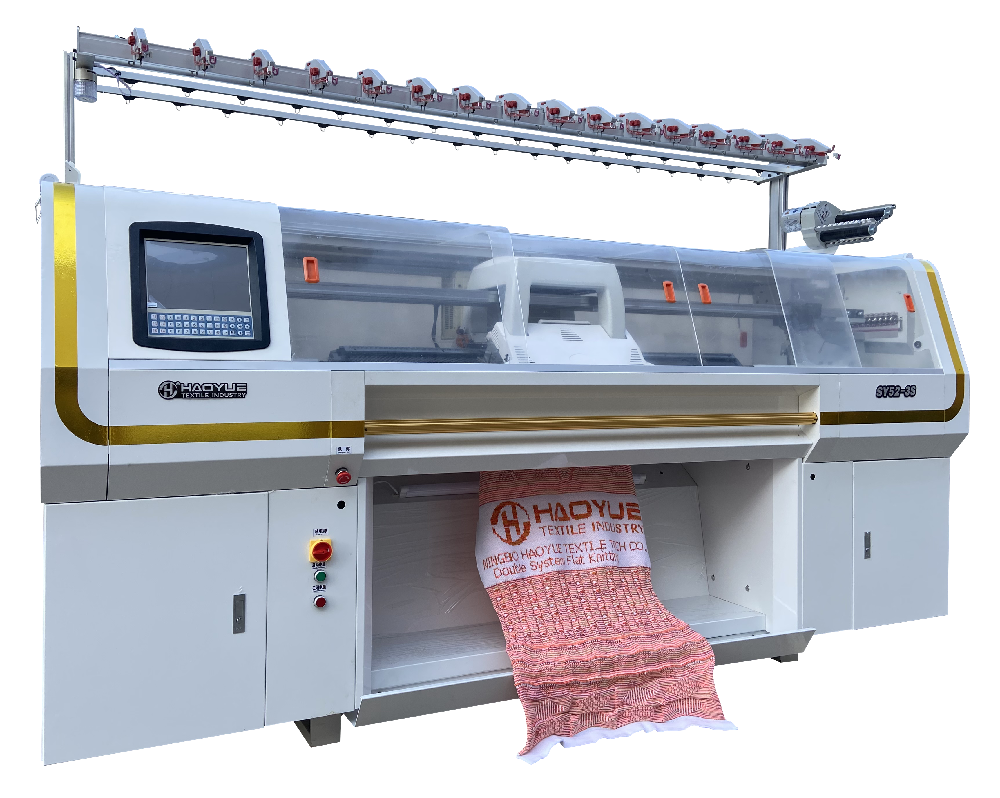

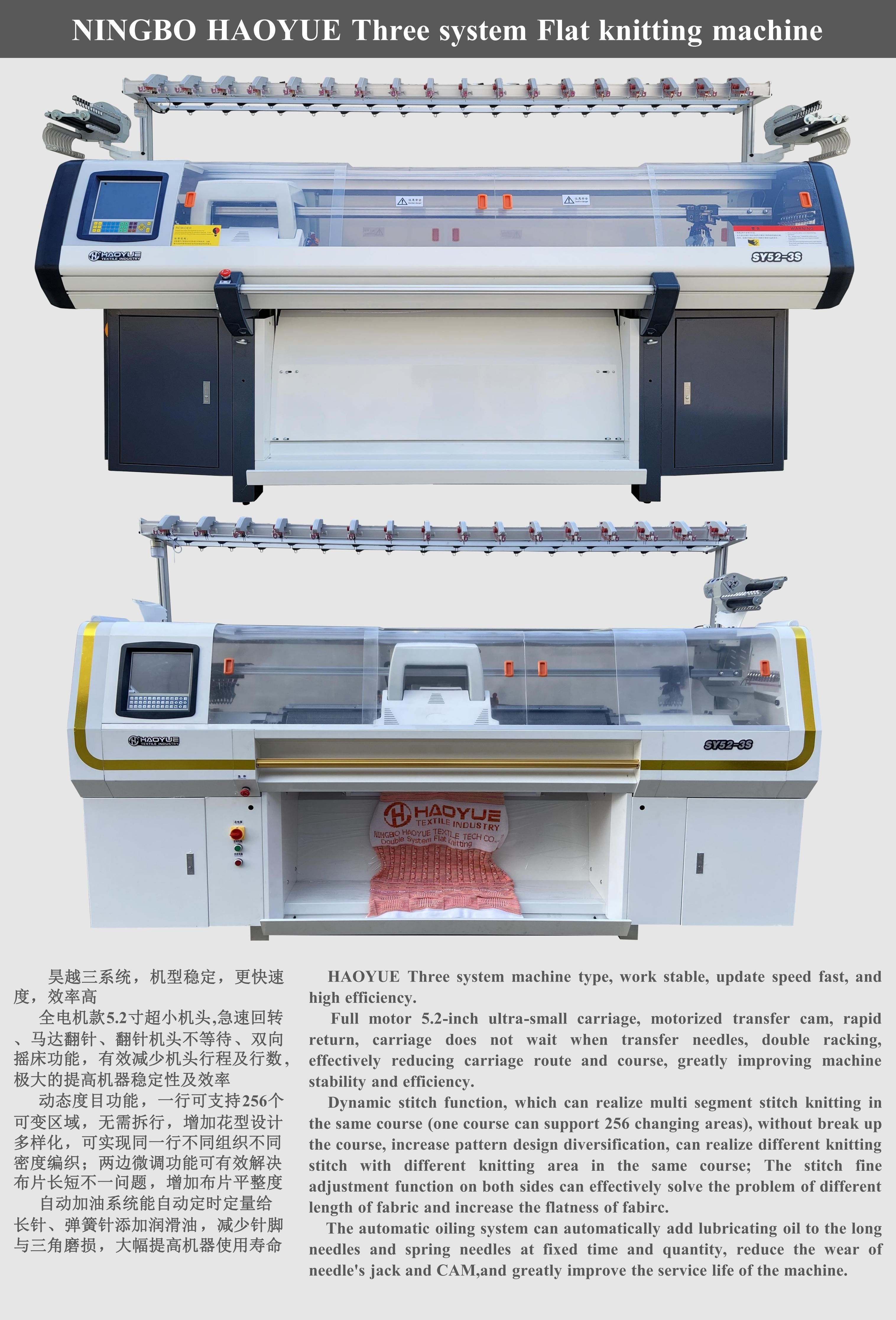

NINGBO HAOYUE Three system Flat knitting machine:

HAOYUE Three system machine type, work stable, update speed fast, and high efficiency.

Full motor 5.2-inch ultra-small carriage, motorized transfer cam, rapid return, carriage does not wait when transfer needles, double racking, effectively reducing carriage route and course, greatly improving machine stability and efficiency.

Dynamic stitch function, which can realize multi segment stitch knitting in the same course (one course can support 256 changing areas), without break up the course, increase pattern design diversification, can realize different knitting stitch with different knitting area in the same course; The stitch fine adjustment function on both sides can effectively solve the problem of different length of fabric and increase the flatness of fabirc.

The automatic oiling system can automatically add lubricating oil to the long needles and spring needles at fixed time and quantity, reduce the wear of needle's jack and CAM,and greatly improve the service life of the machine.

1. Single carriage double system. The double system can work together and separate, enhancing the productivity greatly.Also have three function of knit, tuck and no-knit in the same knitting line and system.

2. Equip with the dynamic stitch function, enable the machine to knit mush wider range of patterns, It can knit different density at same line which break the old knitting method of same line can only have same density. The pattern knitted by dynamic stitch function can have more 3D effect.

3. High-speed reversal to effectively increase the knitting speed by 20-30%.

4. This series is used digital technology to achieve the patterns of transfer, tuck, pointelle, intarsia, jacquard, apparent shaping, hidden shaping and other regular pattern knitting functions, it also can knit irregular multi-colored jacquard, intarsia, cable and Pointe-le structure patterns.

5. New outlook, machine with yarn cone stand at the back.

|

|

|

|

High quality mountain plate, controlled by step motor, the property is more stable. |

The needle is full-insert type, that is, the insertion piece could be replaced when broken, which makes the marginal cost substantially lower. |

|

|

|

|

Linear velocity of head can reach 1.6m/s. The stroke can be adjusted according the weaving width. Fast response, accurate location can avoid the invalid movement and increase the production efficiency. Each system is equipped with five functions as stich transfer, weaving, hanging head, non-weave and pin. Also it can execute color changing via motor, This keeps good balance of routing. reliable, noiseless, etc. |

Positive yarn storage can effectively reduce the resistance when delivering the yarn, especially apply to yarns with little stretch or large brittleness, such as cashmere, rabbit hair and other yarn fabric. Yarn Feeder ensures fabric to become homogeneous or similar and thus increase the weaving efficiency.

|

|

SPECIFICATION, GAUGE AND TECHNICAL PARAMETER |

|

| Gauge | 3G,3.5G,5G,7G,8G,9G,10G,12G,14G,16G,3-5-7G multi-gauge |

| Knitting width | 52,56,60,66,68,72,80, 100 inch |

| Knitting system | Single carriage with three system |

| Knitting function | Knit, miss, turk, transfer, pointel, intarsia, jacquard, apparent or hide shaping and other regular or irregular patterns |

| Knitting speed | Controlled by sevro-motor with 32 sections optional, max speed reach 1.6M/S. |

| Racking | Controlled by sevro-motor racking within 2 inches and with fine adjusting function. |

| Needle selection | Advanced encoder reading pin.8-stage selecting needle setup composed of special electromagnet is regarded as efficient full width jacquard needle selector. |

| Stitch density | Controlled by stepping motor, 32 section stitch selectable adjustable scope supported by subdivision technology: 0-650, the stitch of the knitwear can be accurately controlled. |

| Transfer | Combined design, single or double cam system all can transfer together or separately. Also one cam do transfer, another cam system for knitting, which will achieve high production. |

| Sinker system | Controlled by stepping motor, adjustable to different knitwear, up to be various results of shaping and patterns. |

| Comb device | Grip or knock-over the yam reliably (Optional) |

| Cutters and Grippers | Include 2 cutters and 4 grippers, controlled by 6 motors respectively(Optional) |

| Take-down system | Computer programs instruction,stepper motor control and 32-stagetension selection with an adjustable range between 0-100 |

| Color-changing sytem | 2×8 yarn feeders at the single side of 4 guide rails, shiftable on any needle position. |

| Protection system | The machine will automatically alarm if yarn-breaking, knots, floating yarn, rewind, end of knitting, fail of racking, needle breakage, error programming occur, also set up the safety auto-lock protect device. |

| Control system |

1. LCD industrial display, Can display various parameters, which can be adjustable during operation. 2. USB memory interface,System memory 1G. 3. Free design system is visual and easy to understand and software upgrade free of charge. Support multi-language operation as Chinese and English, Spanish, Russian etc. |

| Network fuction | Has network interface,enable remote-monitoring via network,and connecting with ERP system. |

| Power | Single-phase 220V/three-phase 380V,adopt advanced CMOS technology, having memorizing function at power shock stop. |