- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Boyou

-

Voltage:

-

220V/380V

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Other

-

Product name:

-

Hair Lotion Face Cream Vacuum Emulsifying Mixer

-

Function:

-

mixing tank homogenizer

-

Homogenizer:

-

bottom homogenizer

-

Homogenizer Speed:

-

0-3000 RPM

-

Top Mixer:

-

0-60 RPM

-

Stirrer Type:

-

wall scraper mixer or paddle mixer

-

Heating Method:

-

Electric Steam Heating

-

Volume:

-

100L~10000L

-

Delivery Time:

-

20 days

Quick Details

-

Barrel Volume (L):

-

1000

-

Max. Loading Volume (L):

-

1000 L

-

Range of Spindle Speed(r.p.m):

-

1 - 60 r.p.m

-

Weight (KG):

-

1200 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Boyou

-

Voltage:

-

220V/380V

-

Power (kW):

-

3 kW

-

Marketing Type:

-

Other

-

Product name:

-

Hair Lotion Face Cream Vacuum Emulsifying Mixer

-

Function:

-

mixing tank homogenizer

-

Homogenizer:

-

bottom homogenizer

-

Homogenizer Speed:

-

0-3000 RPM

-

Top Mixer:

-

0-60 RPM

-

Stirrer Type:

-

wall scraper mixer or paddle mixer

-

Heating Method:

-

Electric Steam Heating

-

Volume:

-

100L~10000L

-

Delivery Time:

-

20 days

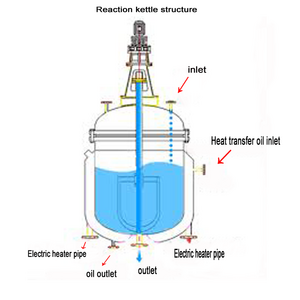

Products Description

cosmetic lotion cream jacketed mixing tank equipment high shear vacuum emulsifier mixer homogenizer with agitator

◆The vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include top homogenization, bottom homogenization, internal and external circulating homogenization. The mixing systems include single-way mixing, double-way mixing and helical ribbon mixing. The lifting systems include single-cylinder lifting and

double-cylinder lifting. Various high quality products can be customized according to customer requirements.

◆The triple mixing adopts the imported frequency converter for speed adjustment, which can meet different technological demands.

◆The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4,200rpm and the highest shearing fineness can reach 0.2-5μm.

◆The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid dust.

◆The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge.

◆The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.

◆According to technological requirements, the tank body can heat or cool the materials. The heating modes mainly include steam heating or electric heating.

◆To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.

double-cylinder lifting. Various high quality products can be customized according to customer requirements.

◆The triple mixing adopts the imported frequency converter for speed adjustment, which can meet different technological demands.

◆The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4,200rpm and the highest shearing fineness can reach 0.2-5μm.

◆The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid dust.

◆The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more obvious, the emulsifying pot can adopt tilt discharge.

◆The pot body is welded by imported three-layer stainless steel plate. The tank body and the pipes adopt mirror polishing, which fully conforms to GMP requirements.

◆According to technological requirements, the tank body can heat or cool the materials. The heating modes mainly include steam heating or electric heating.

◆To ensure the control of the whole machine is more stable, the electric appliances adopt imported configurations, so as to fully meet the international standards.

vacuum emulsifier mixer with 2pcs preheating tanks for oil and water preheating;

vacuum emulsifier mixer, main emulsifier tank;

with platform

Vacuum Emulsifier Mixing Tank with legs

1. single way mixing direction;

2. standard bottom homogenizer;

1. single way mixing direction;

2. bottom internal external circulation homogenizer;

1. double way mixing directions (clockwise + anti-clockwise mixing) ;

2. standard bottom homogenizer;

1. double way mixing directions (clockwise + anti-clockwise mixing);

2. bottom internal external circulation homogenizer;

Application

Product Paramenters

|

Model

|

Capacity

|

Top Mixer Power/Speed

|

Bottom Homogenizer Power/Speed

|

Heating Method

|

||||

|

VME-100L

|

100 Liter

|

1.5KW/0-60RPM

|

2.2KW/0-3000RPM

|

electric or steam heating optional

|

||||

|

VME-200L

|

200 Liter

|

2.2KW/0-60RPM

|

3KW/0-3000RPM

|

|

||||

|

VME-300L

|

300 Liter

|

3KW/0-60RPM

|

3KW/0-3000RPM

|

|

||||

|

VME-500L

|

500 Liter

|

3KW/0-60RPM

|

5.5KW/0-3000RPM

|

|

||||

|

VME-1000L

|

1000 Liter

|

5.5KW/0-60RPM

|

7.5KW/0-3000RPM

|

|

||||

|

VME-1500L

|

1500 Liter

|

5.5KW/0-60RPM

|

7.5KW/0-3000RPM

|

|

||||

|

VME-2000L

|

2000 Liter

|

7.5KW/0-60RPM

|

11KW/0-3000RPM

|

|

||||

|

VME-3000L

|

3000 Liter

|

11KW/0-60RPM

|

18KW/0-3000RPM

|

|

||||

|

The above parameters are for reference ONLY, customerized machines are acceptable.

|

|

|

|

|

||||

Product packaging

Hot Searches