- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

25000 KG

-

Feature:

-

adhesive tape coating equipment

-

Model:

-

bopp tape coating machine

-

Substrate thickness:

-

12-100um

-

Coating Mode:

-

Comma Blade, Slit die, reverse gravure, micro-gravure

-

Name:

-

coating tape machine

-

Machinery Speed:

-

5-30m/min

-

Compound Material Thinkness:

-

PE/PET

-

Heating Method:

-

Electricity

-

Coating Thickness:

-

2-100um for first layer

-

Coating Width:

-

1600mm

Quick Details

-

Voltage:

-

220kv

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

4800L*2000W*2200H

-

Weight:

-

25000 KG

-

Feature:

-

adhesive tape coating equipment

-

Model:

-

bopp tape coating machine

-

Substrate thickness:

-

12-100um

-

Coating Mode:

-

Comma Blade, Slit die, reverse gravure, micro-gravure

-

Name:

-

coating tape machine

-

Machinery Speed:

-

5-30m/min

-

Compound Material Thinkness:

-

PE/PET

-

Heating Method:

-

Electricity

-

Coating Thickness:

-

2-100um for first layer

-

Coating Width:

-

1600mm

Products Description

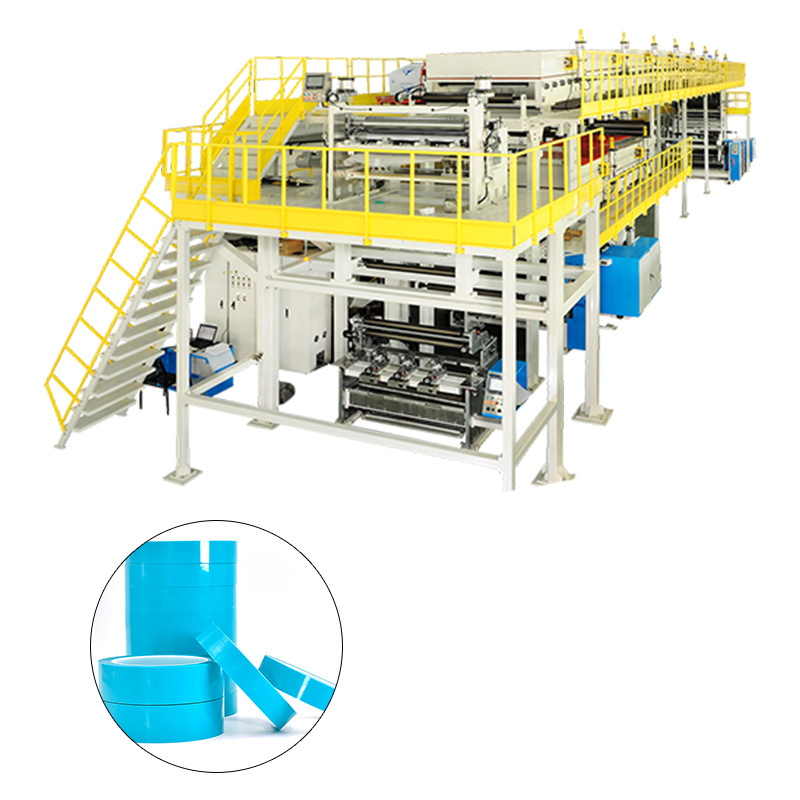

Special Adhesive Bopp Tape Coating & Laminating Machine Equipment

Special tape is widely used in packaging, thermoplastic, composite, sealing heat-sealing, electronic and electrical industries. It exists in all parts that need anti-sticking, heat sealing, corrosion resistance, insulation, etc.

Some stations in the process of coiled material processing are often accompanied by high temperature, which not only needs to protect the processed materials or the guide roller of the transferred materials, but also needs to ensure smooth and wear-resistant surface, so that the processed materials can be smoothly and continuously transmitted.

Some stations in the process of coiled material processing are often accompanied by high temperature, which not only needs to protect the processed materials or the guide roller of the transferred materials, but also needs to ensure smooth and wear-resistant surface, so that the processed materials can be smoothly and continuously transmitted.

Used as the base material of adhesive tape, and its high temperature resistance, flexibility, abrasion resistance and smooth surface are the core of this series of adhesive tape. With the high temperature resistant silica gel adhesive, the perfect combination is achieved.

Equipment characteristics

|

No.

|

Item

|

Technical Specification

|

Remark

|

|

1

|

Substrate Thickness

|

12-100um

|

Normal

|

|

2

|

Coating Mode

|

Reverse gravure, micro-gravure, comma blade, slot die coating, etc

|

Depending on Customer's Process

|

|

3

|

Max Substrate Width

|

1600mm

|

Normal

|

|

4

|

Machinery Speed

|

5-30m/min

|

Depending on Customer's Specific Process

|

|

5

|

Coating Thickness

|

The first layer: 2-10um

The second layer: 15-60um

|

Normal

|

|

6

|

Max Temperature of Dryer

|

180C

|

Normal

|

|

7

|

Compound Material Thickness

|

PE/PET 12-100um

|

Normal

|

Specific Feature

1. Guide edge leather belt

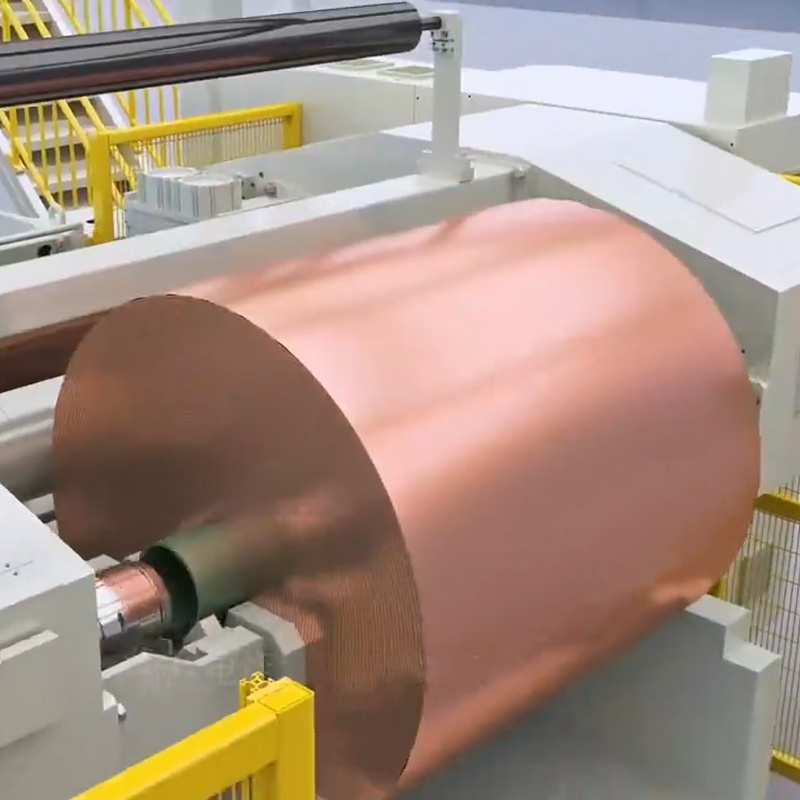

2. Roller coating: coating (coating) the melted liquid PE on the surface of cardboard or other materials (such as film, aluminum foil, etc.). In this coating process, it is necessary to use two adhesive tapes to make a closed leather belt, leather belt rotate together with the machine to protect the cold cylinder (cooling cylinder) and prevent the liquid high temperature PE at the edge from polluting or scalding the cylinder. Generally, the corresponding positions of the inner and outer edges of the cardboard need a leather belt.

On the surface of the transmission roller to prevent contamination or scalding of the guide roller by liquid high-temperature PE. Generally, there are several ways to cover the whole roller surface, partial or edge.

Product features

2. Roller coating: coating (coating) the melted liquid PE on the surface of cardboard or other materials (such as film, aluminum foil, etc.). In this coating process, it is necessary to use two adhesive tapes to make a closed leather belt, leather belt rotate together with the machine to protect the cold cylinder (cooling cylinder) and prevent the liquid high temperature PE at the edge from polluting or scalding the cylinder. Generally, the corresponding positions of the inner and outer edges of the cardboard need a leather belt.

On the surface of the transmission roller to prevent contamination or scalding of the guide roller by liquid high-temperature PE. Generally, there are several ways to cover the whole roller surface, partial or edge.

Product features

Excellent wear resistance, can ensure long-term production without downtime.

Excellent silica gel adhesive to reduce the risk of residual adhesive or overflowing adhesive.

Excellent temperature resistance, release anti-sticking property and tensile strength, no additional adjustment or setting on the equipment is required

Excellent silica gel adhesive to reduce the risk of residual adhesive or overflowing adhesive.

Excellent temperature resistance, release anti-sticking property and tensile strength, no additional adjustment or setting on the equipment is required

In the application field

1. Textured tape

A kind of decorative adhesive tape, which is mostly used to beautify handicrafts, gift packaging, hand-made and other occasions. With rich colors and patterns, mute glue is very suitable for DIY enthusiasts.

2. Double sided tape

A kind of adhesive tape with strong adhesion. It has glue on both sides, which can firmly stick two different materials together. It is often used for bonding paper, wood, metal, plastic and other materials, and is widely used in advertising, printing, home decoration and other fields.

3. Insulating tape

A kind of tape that can prevent current flow and is mainly made of polyethylene, PVC and other materials. Its main function is to insulate, twine and locate the line to ensure the safety and stability of the line. It is widely used in electronic, electrical, communication and other fields.

4. Non-slip adhesive tape

Anti-skid adhesive tape is a kind of adhesive tape that can effectively prevent personnel from slipping. It is often used in public areas, stairs, aisles and other places that need anti-skid. Non-slip adhesive is available in a variety of colors and sizes, suitable for different occasions and needs.

5. Sealing tape

Sealing tape is a kind of tape that can be sealed and soundproof. It is mainly made of foam polyethylene, butyl rubber and other materials. It is mainly suitable for buildings, automobiles, furniture and other fields, with good sealing and sound insulation effect.

In addition, there are fire-proof tapes, conductive tapes, radiation-proof tapes, etc . Different types of special glue have different characteristics and application scope.

A kind of decorative adhesive tape, which is mostly used to beautify handicrafts, gift packaging, hand-made and other occasions. With rich colors and patterns, mute glue is very suitable for DIY enthusiasts.

2. Double sided tape

A kind of adhesive tape with strong adhesion. It has glue on both sides, which can firmly stick two different materials together. It is often used for bonding paper, wood, metal, plastic and other materials, and is widely used in advertising, printing, home decoration and other fields.

3. Insulating tape

A kind of tape that can prevent current flow and is mainly made of polyethylene, PVC and other materials. Its main function is to insulate, twine and locate the line to ensure the safety and stability of the line. It is widely used in electronic, electrical, communication and other fields.

4. Non-slip adhesive tape

Anti-skid adhesive tape is a kind of adhesive tape that can effectively prevent personnel from slipping. It is often used in public areas, stairs, aisles and other places that need anti-skid. Non-slip adhesive is available in a variety of colors and sizes, suitable for different occasions and needs.

5. Sealing tape

Sealing tape is a kind of tape that can be sealed and soundproof. It is mainly made of foam polyethylene, butyl rubber and other materials. It is mainly suitable for buildings, automobiles, furniture and other fields, with good sealing and sound insulation effect.

In addition, there are fire-proof tapes, conductive tapes, radiation-proof tapes, etc . Different types of special glue have different characteristics and application scope.

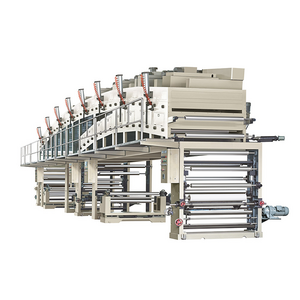

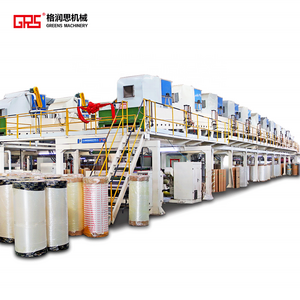

Functional film equipment:

OCA(

Optical Clear Adhesive) Coating & Laminating Machine(with UV)

Quantum Dot Film Coating Machine

Protective Film/Release Film Coating & Laminating machine

Water Treatment RO Membrane Machine

Fuel Cell Membrane Electrode Assemby Coating Machine

EMI (Electromagnetic)Shielding Film Coating & Laminating Machine

FCCL (Flexible Copper Clad Laminate)Coating & Laminating Machine

PDLC,UVOCA Adhesive,Electronic Drawing Board Wet Laminating Mchine

Special Tape Coating & laminating Mchine

Double Side Aluminum Foil Coating Machine

Double-side Membrane Coating Machine

NC Film (Biofilm)Coating Machine

Photovoltaic/Fuel Cell Flat Coating Machine

Aluminum Plastic Film Coating and laminating Machine

Coating Mode

Closed Micro Gravure Double-side Closed Micro Slot Die Transferred Lip Slot Die Coating

Coating Gravure Coating

Coating

Slot Die Coating Stripped Slot Die Coating Double-layer Slot Die Micro Gravure Coating

Coating

Hot Searches