- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer

-

Dimension(L*W*H):

-

4500*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or Based on design drawing

-

Product name:

-

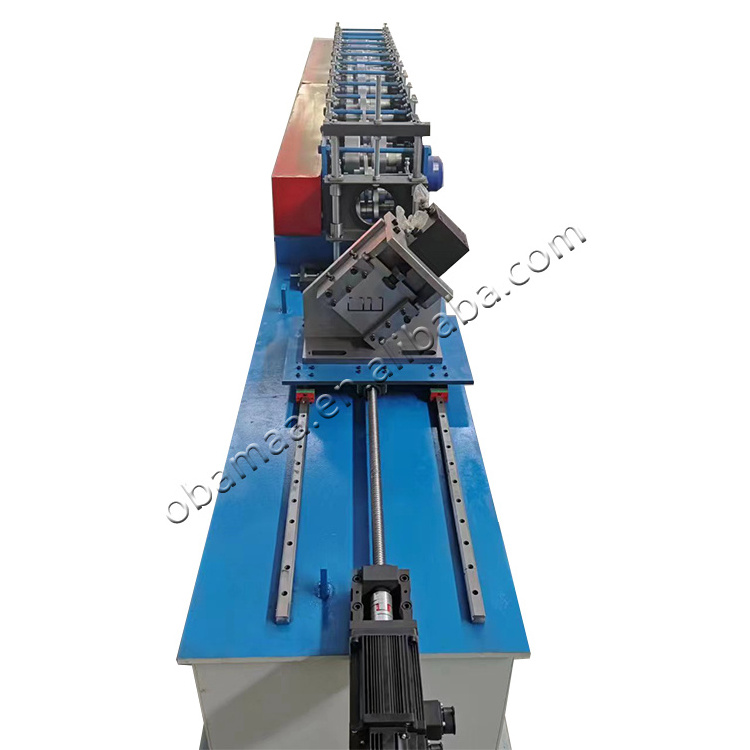

C purlin roll forming machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3--0.8mm

-

Usage:

-

Building Roof

-

Cutting system:

-

Hydraulic Automatic Cutter

-

Roller Stations:

-

11/16Steps

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Galvanized steel Plate

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20-50m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jane

-

Voltage:

-

380V 50HZ 3P or Customize as customer

-

Dimension(L*W*H):

-

4500*800*1000mm

-

Weight:

-

2500 kg

-

Feeding width:

-

1200mm or Based on design drawing

-

Product name:

-

C purlin roll forming machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Thickness:

-

0.3--0.8mm

-

Usage:

-

Building Roof

-

Cutting system:

-

Hydraulic Automatic Cutter

-

Roller Stations:

-

11/16Steps

-

Roller material:

-

45# Forged Steel

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Galvanized steel Plate

Products Description

C purlin roll forming machine

C purlin roll forming machines are used in the construction industry to produce high-quality purlins, which are used to support the roof and walls of buildings. These machines are designed to produce purlins in various sizes and shapes, depending on the requirements of the building project.

Work processing

Specification

|

C purlin roll forming machine

|

|

|

|

|||

|

SN

|

Part details

|

Item Name

|

Specification

|

|||

|

1

|

Material

|

Raw material

|

Steel

|

|||

|

|

|

Thickness

|

0.3-0.8 mm

|

|||

|

2

|

Machine

|

Roller station

|

11/16Steps

|

|||

|

|

|

Shaft diameter

|

55 mm

|

|||

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|||

|

|

|

Roller material hardness 30-40 HRC

|

Cr 12

|

|||

|

|

|

Machine size

|

4500*800*1000mm

|

|||

|

|

|

Machine weight

|

About 2.5 ton

|

|||

|

|

|

Machine color

|

As customer' request

|

|||

|

|

|

Working speed

|

20-50 m/min

|

|||

|

3

|

Cutter

|

Operate

|

Hydraulic cutting

|

|||

|

|

|

Material

|

Cr 12

|

|||

|

|

|

Hardness

|

50-65 HRC

|

|||

|

|

|

Cutting tolerance

|

± 1 mm

|

|||

|

4

|

Power

|

Main power

|

4 kw

|

|||

|

|

|

Pump power

|

3 kw

|

|||

|

|

|

Driving way

|

Chain 1 inch

|

|||

|

|

|

Voltage

|

Customize as customer' request

|

|||

|

5

|

Control system

|

Language

|

English or add language as customer need

|

|||

|

|

|

PLC brand

|

Delta or customize as customer' request

|

|||

|

|

|

Screen

|

Touchable screen

|

|||

|

6

|

Decoiler

|

Operation

|

Manual

|

|||

|

|

|

Weight capicatity

|

3 tons or 5 tons

|

|||

|

|

|

Price

|

Free as gift

|

|||

|

7

|

Receiving table

|

Operation

|

Manual

|

|||

|

|

|

Length

|

3 m

|

|||

|

|

|

Price

|

Free as gift

|

|||

Product Details

The fully automatic C purlin forming machine can produce different sizes of C purlins through an automatic/manual simple control system.

This flexibility makes them an ideal solution for any construction project, whether it is a small residential building or a largecommercial structure.

The purlin roll forming machines are also highly customizable, allowing builders to produce purlins in a variety of shapes and sizes to meet the specific needs of their construction projects.

The purlin roll forming machines are an essential tool for any construction project.They are efficient, durable, flexible, and environmentally friendly, making them a cost-effective and sustainable solution for any builder or contractor.

In addition to their efficiency and durability, purlin roll forming machines are also environmentally friendly. They use less energy than traditional manufacturing methods, making them a more sustainable option for construction projects.

Hydraulic shearing adopts vertical punching shearing, with large shearing force and no burr.The shear adopts the vertical punching type, the overall frame structure, the slide positioning type.Shear strength is strong, convenient maintenance.

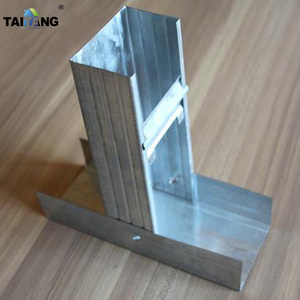

Sample Room

Finished product effect for your reference.

The following are the products produced by our machine. Please check the rolling forming effect.

Other Product

Packing&Delivery

Hot Searches