- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor

-

Design Style:

-

Traditional

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YC

-

Model Number:

-

SFA-1

-

Product name:

-

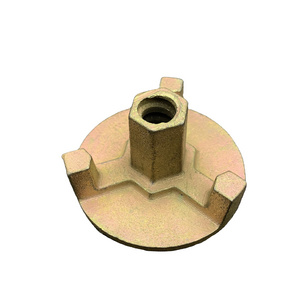

Formwork Wing Nut

-

Material:

-

Carbon Steel

-

Surface treatment:

-

Zinc Coated

-

Raw material:

-

Low Carbon Steel Wire Q235

-

Color:

-

Silver Gloden Black

-

Sample:

-

Accept

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

NONE

-

Project Solution Capability:

-

NONE

-

Application:

-

Outdoor

-

Design Style:

-

Traditional

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

YC

-

Model Number:

-

SFA-1

-

Product name:

-

Formwork Wing Nut

-

Material:

-

Carbon Steel

-

Surface treatment:

-

Zinc Coated

-

Raw material:

-

Low Carbon Steel Wire Q235

-

Color:

-

Silver Gloden Black

-

Sample:

-

Accept

Products Description

We have all kinds of scaffolding accessories for sale. All our scaffolding accessories are made as per European standard, and all our customers are very happy with our quality,price and services. Our factory can design and manufacture any new products for our customers according to the drawings or samples.

|

Product Name

|

FORMWORK TIE NUT

|

|

Plate sizes

|

60mm, 70mm, 80mm, 90mm, 100mm, 110mm, 120mm, 130mm

|

|

Diameter

|

D15mm, D20mm

|

|

Weight

|

350g, 410g, 450g, 550g, 600g, 650g, 780g

|

|

Surface Finish

|

Galvanized

|

|

Material

|

Ductile Iron Casting

|

|

Color

|

Gold, Silver

|

Tie Nut:

There are single wing nut, butterfly wing nut, two anchor wing nut, three anchor wing nut, combination wing Nut. Because of this structure, wing nuts can be easily tightened and loosened by hand without any tools. Wing nuts have casting and forging types by processing technology , common thread size is 17mm/20mmon .

|

Product Name

|

FORMWORK TIE ROD

|

|

Sizes

|

12MM, 15MM, 20MM

|

|

Diameter

|

D10/12MM D15/17MM D20/22MM

|

|

Weight

|

0.75KG/METER; 1.50KG/METER; 2.25KG/METER

|

|

Breaking Load

|

90KN 140KN 260KN

|

|

Surface Finish

|

Galvanized

|

Product Application

Company introduction

Cangzhou Yingchao Hardware Manufacturing Co., Ltd. founded in 2003, is a medium-scale professional manufacturer of casting, metal stamping and building templates systems. Business scope: valve casting and processing; construction accessories, metal stamping, scaffolding & templates & wooden beam system sales and leasing.

Our company is a professional manufacturer of building systems and accessories, valve castings, with an annual production capacity of 12,000 tons of ductile iron castings and 5,000 sets of templates systems. We are one of the largest manufacturer of valve casting, building formwork and accessories in North China.

Our company has several domestically advanced intermediate frequency melting furnaces, and uses clay-sand technology to produce iron castings.The factory is equipped with advanced and complete casting production testing equipments including: spectrometer, carbon and sulfur analyzer, metallographic microscope, furnace analyzer, universal material testing machine, Brinell hardness tester, visible spectrophotometer, intelligent air permeability strength tester, etc...It can provide reliable detection information on the material and intrinsic quality of castings. At the same time, our company has a scientific and technological team composed of a group of high and intermediate technical personnel, advanced technology, equipment and efficient scientific management system to ensure continuous improvement of product quality, and has obtained the quality management system certification (GB/T 19001-2016/ ISO 9001:2015 standard).

Our company has several domestically advanced intermediate frequency melting furnaces, and uses clay-sand technology to produce iron castings.The factory is equipped with advanced and complete casting production testing equipments including: spectrometer, carbon and sulfur analyzer, metallographic microscope, furnace analyzer, universal material testing machine, Brinell hardness tester, visible spectrophotometer, intelligent air permeability strength tester, etc...It can provide reliable detection information on the material and intrinsic quality of castings. At the same time, our company has a scientific and technological team composed of a group of high and intermediate technical personnel, advanced technology, equipment and efficient scientific management system to ensure continuous improvement of product quality, and has obtained the quality management system certification (GB/T 19001-2016/ ISO 9001:2015 standard).

FAQ

1. How to start OEM orders?

2. What are your terms of payment?

We accept t/T, l/C, trade assurance, credit card, Western Union, etc.

3. Can you customize the packaging?

The logo, carton and pallet can be customized.

4. How do you guarantee the quality of your products?

Better control from raw materials, production, processing, packaging, storage until to shipment. And we passed the ISO9001 quality management system certification.

5. What kind of payment terms you use for ship the gods?

We support FOB, CIF, CFR, DDU, DDP and so on, we have very rich experience ship gods directly to customer's plant.

6. After-sales.

Quick response day and night.

Send drawing or sample - get price - pay - make mold - confirm sample - mass production-payment-delivery.

2. What are your terms of payment?

We accept t/T, l/C, trade assurance, credit card, Western Union, etc.

3. Can you customize the packaging?

The logo, carton and pallet can be customized.

4. How do you guarantee the quality of your products?

Better control from raw materials, production, processing, packaging, storage until to shipment. And we passed the ISO9001 quality management system certification.

5. What kind of payment terms you use for ship the gods?

We support FOB, CIF, CFR, DDU, DDP and so on, we have very rich experience ship gods directly to customer's plant.

6. After-sales.

Quick response day and night.

Hot Searches