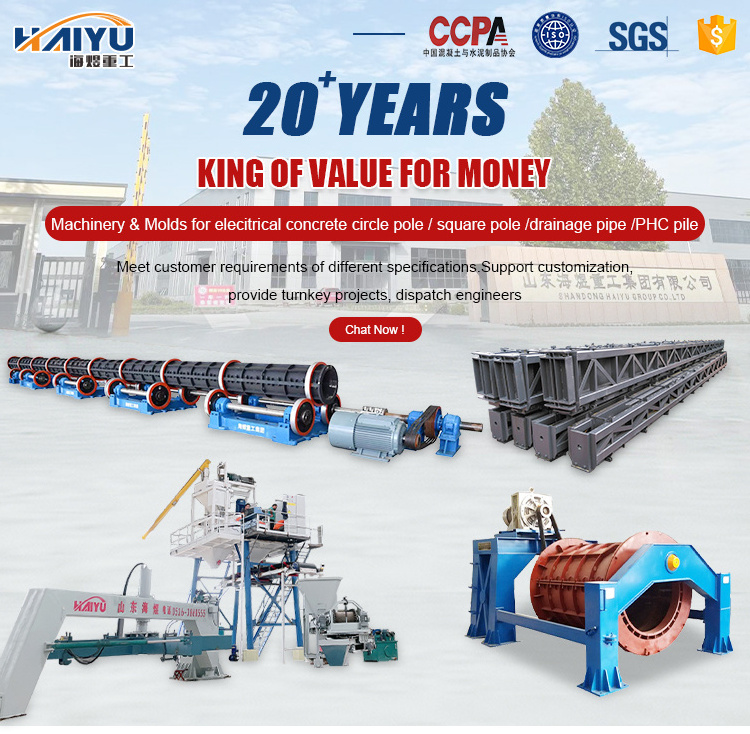

Precast reinforced box culvert are strong, comparatively easy to install, and offer a modern solution to a wide variety of highway bridge problems and drainage conditions, including both storm and sanitary sewers. They avoid many of the problems encountered with cast-in-place culverts such as weather and form construction. They take less time from start to completion of installation;

they can be made with uniform high quality throughout; and if, at a later date, the line needs to be extended, it is much easier with precast box culverts than with cast in place. To get box culvert equipment that is well designed, versatile, long-lasting, and economical both to acquire and to operate.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HY

-

Voltage:

-

2000*3252*2200

-

Power:

-

220KV

-

Dimension(L*W*H):

-

2000*3252*2200

-

Weight:

-

8000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

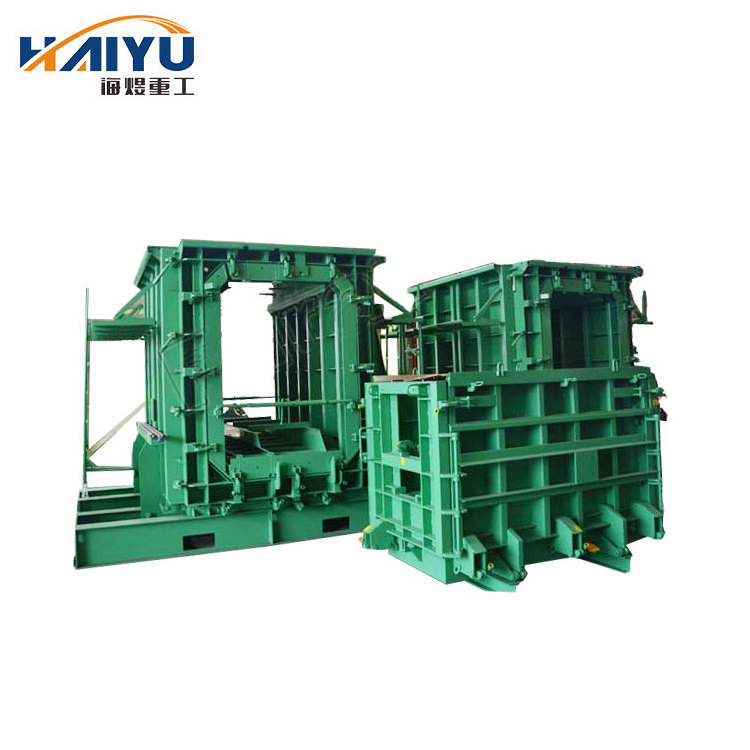

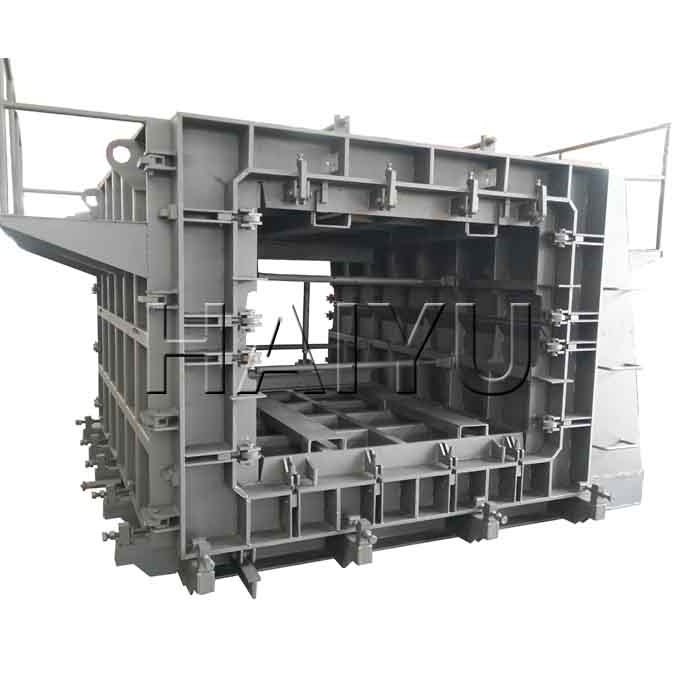

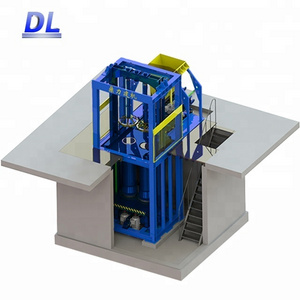

Precast Concrete Cube House Mould Box Culvert Making Machine

-

Market:

-

All over the world

-

Certification:

-

ISO9001

-

Length:

-

1-3m

-

Thickness:

-

120-200mm

-

Hight:

-

1200-1500mm

-

Usage:

-

Drainage

Quick Details

-

Pipe Material:

-

CONCRETE

-

Production Capacity:

-

2pcs per day

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HY

-

Voltage:

-

2000*3252*2200

-

Power:

-

220KV

-

Dimension(L*W*H):

-

2000*3252*2200

-

Weight:

-

8000 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Precast Concrete Cube House Mould Box Culvert Making Machine

-

Market:

-

All over the world

-

Certification:

-

ISO9001

-

Length:

-

1-3m

-

Thickness:

-

120-200mm

-

Hight:

-

1200-1500mm

-

Usage:

-

Drainage

Product Description

Overview of Concrete Box Culvert Mold

Concrete Box Culvert Mold Features

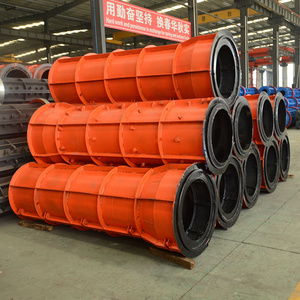

1. Adopting the High Frequency Inner Vibrating, concrete will be easier and more complete to become solid and density, Theconcrete pipe will be better in structure and stable quality.

2. Using the half-dry cast concrete, after the pipe finished, the inner mould andOuter mould will be released instantly, each diameter pipe just need one set of moulds, which will save a lot of moulds moneyinvestment, also save a lot of time for workers assembling and disassembling the moulds, also improve the production efficiency.After releasing the moulds, the pipe could be curing by itself with the cement heat hydration, no need the steam curing, lower the

steam curing cost;

3. Wide range of production, this machine is capable to make not only the RCC pipe, F-joint pipe, Steel jacking pipe, but also theculverts, manholes, and so on.

4. All of our electric motors, and inverters are the variable frequency speed control, the exciting forced are also variablecontrol, with perfect performance, and higher efficiency , for the two stations of machine is capable to make 100m per 8 hours dayfor diameter over 800mm.

2. Using the half-dry cast concrete, after the pipe finished, the inner mould andOuter mould will be released instantly, each diameter pipe just need one set of moulds, which will save a lot of moulds moneyinvestment, also save a lot of time for workers assembling and disassembling the moulds, also improve the production efficiency.After releasing the moulds, the pipe could be curing by itself with the cement heat hydration, no need the steam curing, lower the

steam curing cost;

3. Wide range of production, this machine is capable to make not only the RCC pipe, F-joint pipe, Steel jacking pipe, but also theculverts, manholes, and so on.

4. All of our electric motors, and inverters are the variable frequency speed control, the exciting forced are also variablecontrol, with perfect performance, and higher efficiency , for the two stations of machine is capable to make 100m per 8 hours dayfor diameter over 800mm.

Case Display

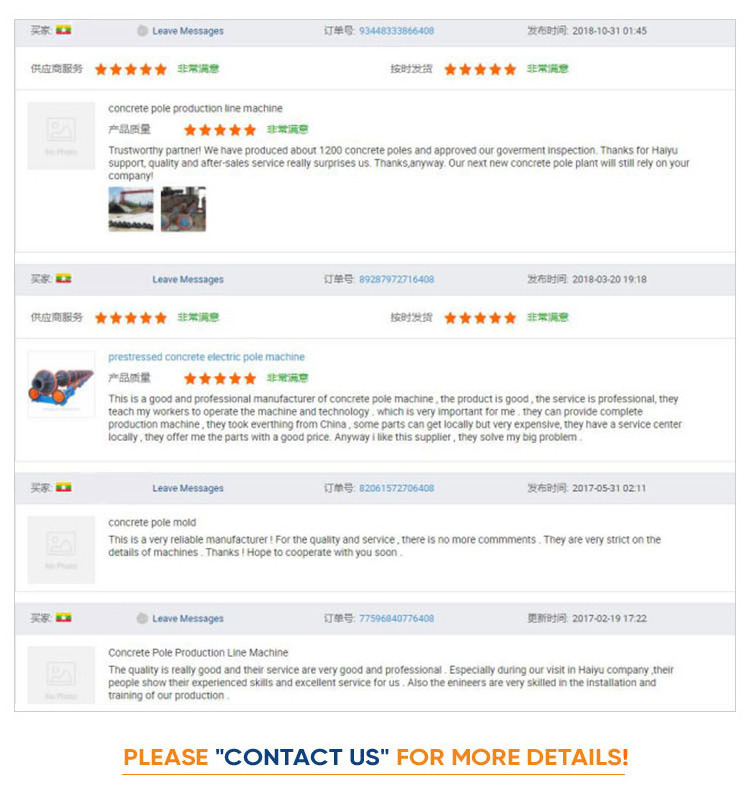

Customer Feedback

Hot Searches