- Product Details

- {{item.text}}

Quick Details

-

High handling capacity:

-

High handling capacity

-

Simple process:

-

Simple process

-

Low cost:

-

Low cost

-

Free of dust pollution:

-

Free of dust pollution

-

Name:

-

Calcium carbonate powder coating machine

-

Certification:

-

CE SGS ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

After-sales Service Provided:

-

Video technical support, Online support, Engineers available to service machinery overseas

-

Good result:

-

Good result

-

High handling capacity:

-

High handling capacity

-

Simple process:

-

Simple process

-

Low cost:

-

Low cost

-

Free of dust pollution:

-

Free of dust pollution

-

Name:

-

Calcium carbonate powder coating machine

-

Certification:

-

CE SGS ISO

Calcium carbonate powder coating machine LHF:

Applications of Calcium carbonate powder coating machine LHF:

LHF series Powder Surface Modifying Machine is mainly used for the surface modification of powder materials (range from 325 mesh to nanometer sized), like ground limestone, precipitated light calcium carbonate, washed kaolin, calcined coal kaolin, magnesium hydrate, superfine and precipitated barite and zinc oxide, etc.

In some occasions, this kind of powder surface modification machine also functions as a disaggregating machine.

Features of Calcium carbonate powder coating machine LHF:

1. Continuous operation is possible, thus guarantee a high production capacity.

2. Working independently or working in a production line (combined use with superfine grinding mills, etc.) are both possible.

3. High coating ratio; high activation index; low consumption of modification agent.

4. No material aggregation: as a result, finished products can be packaged directly.

5. Low power consumption:

--lowest power consumption could be 30 kwh/t;

--self-generated heat of the machine can be directly used for material's surface engineering; as a result, there is no need of any other additional heating system.

6. Modification temperature can be adjusted to meet different requirements.

7. Eco-friendly: negative pressure production help offer a dust-free production environment.

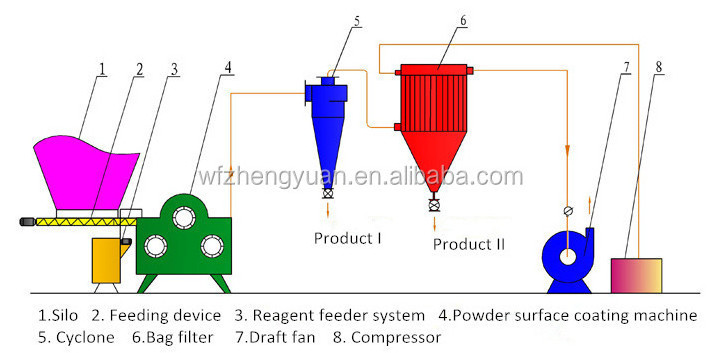

Working Principle of Calcium carbonate powder coating machine LHF:

Feeding material into powder surface modification machine → adding into modification agent → material and modifier will fully mixed together when the modification machine is operating at high speed; and the heat, which is generated for the high speed movement of machine and material, will also help finish material coating at the same time → finally, the finished products will be collected by the negative pressure collection system.

Our main products are Impact Mill, Roll Mill, Rotor Mill, Cutting Mill, Depolymerization Machine, Cyclonic Jet Mill, Air Fluidized Jet Mill, Air Classifiers, Superfine Classifying Ball Mill, Coating Machine and wet grinding mill, about one thousand of grinding and classifying lines have been used both at home and abroad.One large machining center and one assembly center, two labs equipped with the advanced Malvern Mastersizer2000, and large trial rooms where more than 40 sets equipments are installed for 1:1 industrial trial for you at any time.

Zhengyuan has the biggest powder test base in the world equipped with various kinds of trial machines of more than 400 sets. It can meet thousands of powder materials industrial test needs,and also undertakes a variety of powder materials processing business.

Zhengyuan has more than 500 sets various kinds of precision testing equipments and fabricating equipments.Our annual production capacity can reach more than 1000 sets. Zhengyuan was one of the first few companies in the industry that passed the ISO9001 international quality management system certification and CE certification which ensures reliability and security of our products.

Contact person:Kelly Wang

Wechat/whatsapp:0086 134 6566 0184

Tel:86-536-2105390 2105890

Fax:0086 536-2105367