- Product Details

- {{item.text}}

Quick Details

-

Power:

-

adjustable

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100 KG

-

Material:

-

SUS304/316

-

SUS thickness:

-

inner wall 3mm, surface 2mm

-

Heating method:

-

steam/electric/gas

-

Control method:

-

semi-auto control

-

Connect:

-

Tri-clamp

-

Finishing:

-

Mirror polishing≤0.4um

-

Technology:

-

German method

-

Accessary:

-

Valves, pipes, hoses...

-

Capacity:

-

50L-10000L per batch

-

Product Name:

-

hot liquor tank

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Yuesheng

-

Voltage:

-

customized

-

Power:

-

adjustable

-

Dimension(L*W*H):

-

customized

-

Weight:

-

100 KG

-

Material:

-

SUS304/316

-

SUS thickness:

-

inner wall 3mm, surface 2mm

-

Heating method:

-

steam/electric/gas

-

Control method:

-

semi-auto control

-

Connect:

-

Tri-clamp

-

Finishing:

-

Mirror polishing≤0.4um

-

Technology:

-

German method

-

Accessary:

-

Valves, pipes, hoses...

-

Capacity:

-

50L-10000L per batch

-

Product Name:

-

hot liquor tank

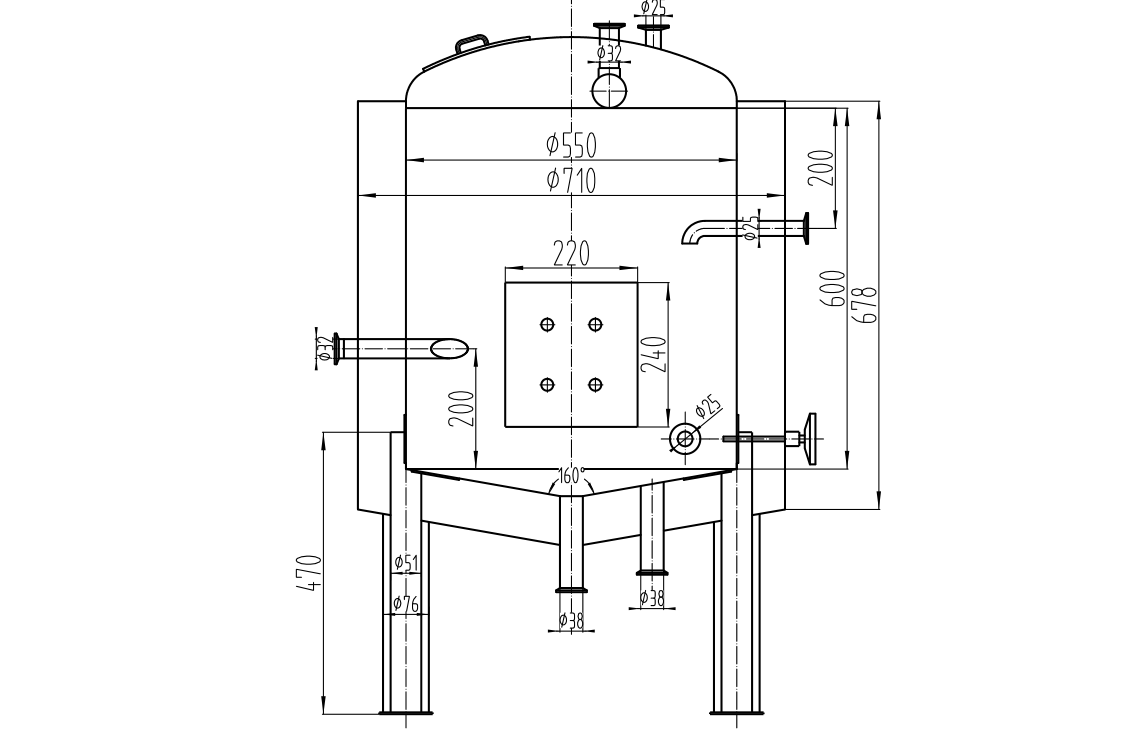

304 stainless steel hot liquor tank hot water tank for beer

Technology Parameters

|

Capacity |

100L |

200L |

300L |

500L |

1000L |

2000L |

|

Model |

SDET-100 |

SDET-200 |

SD-300 |

SDET-500 |

SDET-1000 |

SDET-2000 |

|

15sq.m. |

25sq.m. |

35sq.m. |

45sq.m. |

80sq.m. |

120sq.m. |

|

|

Power consumption |

18KW |

25KW |

29KW |

35KW |

60/20KW |

60/25KW |

|

Fermentation time |

8-12 days |

8-12 days |

8-12 days |

8-12 days |

8-12 days |

8-12 days |

beer brewing equipment configuration

|

Item |

Model |

Technical Specifications |

|

Malt Mill |

300kg/h |

two roller mill, carbon steel shell, alloy rollers complete with motor, belt and pulley, motor power 3kw |

|

Mash/Kettle Tun |

50L,3000L |

effective capacity 500L, total capacity 775L, top dished head,material SS304, interior sand polished, cladding surface mirror finish, welding seams brushed electric heating elements, mineral wool insulation, thickness 80mm, |

|

Lauter/whirpool Tun |

50L,3000L |

effective capacity 500L, total capacity 775L, top dished head, material SS304, interior sand polished, cladding surface mirror finish, welding seams brushed |

|

Fermentation Tank |

50L,3000L |

effective capacity 500L, total capacity 740L, top dished head, bottom cone, material SS304, interior sand polished, |

|

Yeast Adding Tank |

5L |

effective capacity 5L, inside polished outside sand blast, associated valves and fittings |

|

Glycol Tank |

1000L |

effective capacity 1000L, total capacity 1200L, material SUS304, interior sand polished, |

|

Glycol Chiller |

(5HP) |

Refrigeration capacity (5HP), air cooling unit, CE approved, environment protecting Freon, designed for local power supply |

|

Sanitizer Tank |

50L |

effective capacity 50L, interior & exterior 2b finish, welding seams brushed, associated valves and fittings |

|

Caustic Tank |

50L |

effective capacity 50L, interior & exterior 2b finish, welding seams brushed, associated valves and fittings, electric heating elements |

|

Control Cabinet |

700×400×2000 |

power supply, temperature display centrally, brewhouse manual control, fermentation tanks separate control with digital controller separately variable frequency control for motors, pumps, etc. |

|

Digital Controller |

C2015 |

separate control for each fermentation tank, temperature local display & control on controllers |

Production details showcase of beer brewery equipment, micro brewery

Brewery list

| Equipents Request | Components |

| 1. Milling System | Malt Miller |

|

2. Mashing System

|

Mash/Lauter Tun, Boiler Tank, Boiler, Heat Exchanger, Wort Pump, Other accessories are available: 1. Ornamental Pipe; 2. Mashing Pipeline; 3. Operating Plateform; 4. Yeast Feeder; 5. Venturi Tube; 6. Butterfly Valve DN40; 7. Butterfly Valve DN32; 8. Soft Pipe; 9. Dregs Rake; 10. Sugar Measuring Cylinder; 11. Saccharimeter; |

|

3. Fermenting System

|

Fermentation Tank, Other accessories are available: 1. LPipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe; |

|

4. Cooling System

|

Ice Water Tank, Refrigeration Machine, Centrifugal Pump, Evaporator, Ice Water Pump, Relative Pipes and Valves |

|

5. CIP System

|

Washing Tank, Sterilization Tank, Pump and Valve |

|

6. Controlling System

|

Mashing Control Panel, Fermenting Control Panel, Refrigerating Control Panel |

Details

Polishing: Polishing is vital for tanks. Tanks should be polished wholly inside and outside.

Therefore it can ensure there is no place for the bacteria to hide in tanks.

Our polishing system consists of auto and semi-auto polishing machine and manual polishing.

Each tank is polished three times and more polish for the key place.

Welding: Our argon central system for welding provides 100% pure argon to protect tanks from

distorting during welding.

Accessories