No1. Material, 100% virgin UHMWPE raw material;

No2, Extruding

No.3, Inspection and testing

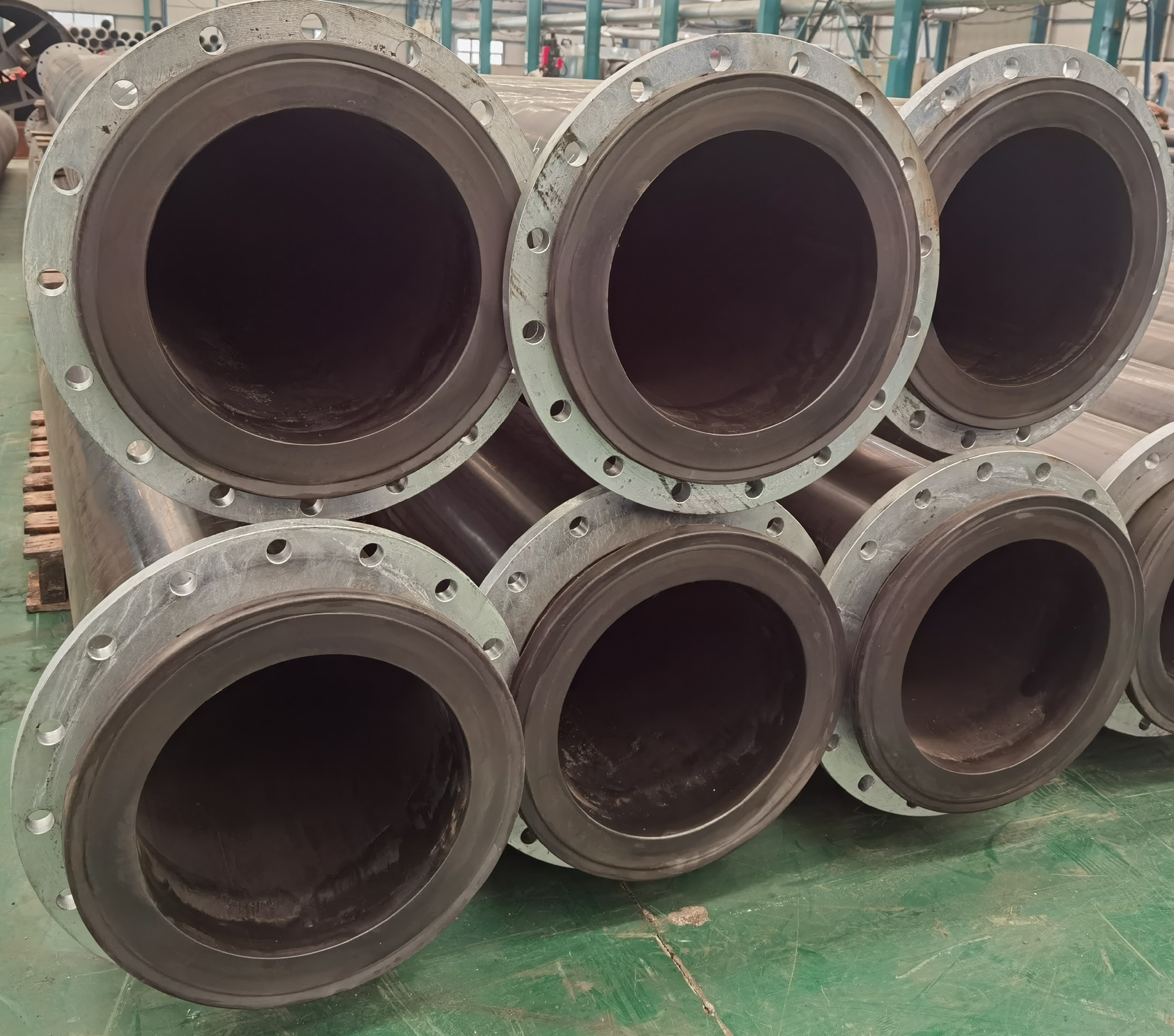

No.4, UHWMPE flange making with machine

No.5, Final checking

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DN300

-

Specification:

-

DN42-DN1200

-

Length:

-

5.8/PC or 11.8/pc

-

Thickness:

-

20

-

Standard:

-

ISO9001

-

Type:

-

dredging

-

Application:

-

sand/slurry

-

Connection:

-

steel flange

-

Color:

-

Black

-

Name:

-

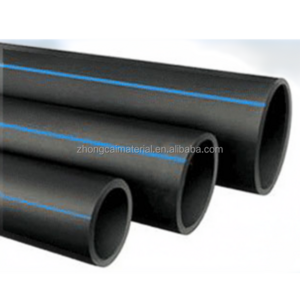

18 INCH UHMWPE sand/slurry Flexible Dredge Pipe

-

Working pressure:

-

0.4~2.0Mpa

-

Usage:

-

Dredging

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

haohua

-

Model Number:

-

DN300

-

Specification:

-

DN42-DN1200

-

Length:

-

5.8/PC or 11.8/pc

-

Thickness:

-

20

-

Standard:

-

ISO9001

-

Type:

-

dredging

-

Application:

-

sand/slurry

-

Connection:

-

steel flange

-

Color:

-

Black

-

Name:

-

18 INCH UHMWPE sand/slurry Flexible Dredge Pipe

-

Working pressure:

-

0.4~2.0Mpa

-

Usage:

-

Dredging

Product Description

UHMWPE Pipe Introduction

Ultra-high molecular weight polyethylene (UHMW-PE) pipelines are made of ultra-high

molecular weight polyethylene raw materials with a viscosity average molecular weight of 3.5 million to 9.2 million. They are extruded under high temperature and high pressure by special machinery. They are widely used in blow filling, dredging, and mine tailings. Mine, ash and slag transportation and other fields.

molecular weight polyethylene raw materials with a viscosity average molecular weight of 3.5 million to 9.2 million. They are extruded under high temperature and high pressure by special machinery. They are widely used in blow filling, dredging, and mine tailings. Mine, ash and slag transportation and other fields.

Production Flow of UHMWPE Pipe

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand

|

haohua

|

|

Dimension

|

Dn300

|

|

Material

|

Other

|

|

Size

|

DN42-DN1200

|

|

Length

|

5.8/PC or 11.8/pc

|

|

|

20

|

|

Certificate

|

ISO9001

|

|

Processing Service

|

Moulding, Cutting, Cutting

|

|

Type

|

dredging

|

|

Application

|

sand/slurry

|

|

Connection

|

steel flange

|

|

Color

|

Black

|

Benefits of UHMWPE Pipe

1,High Wear Resistant

Compare with existing plastic pipes, Wear resistant UNMWPE pipe has the most excellent wear resistance which is 4 to 7 times that of Q235 steel pipe and 2.7 times that of wear-resistant steel 16Mn. Therefore it increases pipe flow rate and improves the transmission efficiency of more than 20%. The working life of UHMWPE pipes is more than 3 times that of wear-resistant steel pipe.Wear resistant UHMWPE pipe has great advantages to replace traditional metal pipes in delivering abrasive media.

2,Impact Resistant

Wear resistant UHMWPE pipe is greatly impact resistant which is 5 times that of HDPE pipe, 2 times that of PC pipe and 10 times that of PTFE pipes.With extraordinary impact resistance,UHMWPE pipe can withstand great water hammer impact when starting up pump station.

3,Low Energy Consumption

Wear resistant UHMWPE pipe is self-lubrication and non-adhesive. Its coefficient of friction resistance is 0.009 while that of steel pipe is 0.013. With the same diameter, flow rate of UHMWPE pipe is larger than steel pipe, and with the same flow rate, UHMWPE pipe can save 25% energy.

4,Non-scaling

With roughness of 0.00022 and smooth pipe inner wall, it can efficiently avoid scaling without acid cleaning, which save a lot of maintenance cost.

5,Anti Low Temperature

At the temperature of -70 ℃,UHMWPE pipe can work with normal mechanical performance. It is suitable for water supply and drainage in cold area.

6,High Pressure Resistant

UHMWPE pipe is high pressure resistant and highly flexible. The compressive strength of UHMWPE pipe is 2 times to that of PE100 pipe and 2.5 times to that of PE80. UHMWPE pipes can withstand wide fluctuate of water pressure in the pipeline.

7,Maintenance Free

With characteristics of corrosion resistance, low temperature resistance, non-scaling, no leakage, etc, UHMWPE pipe can work without extra anticorrosive coating, cleaning and maintenance which save more than 95% energy.

8,Environment Friendly

The manufacturing and processing of wear resistant UHMWPE pipe is low carbon and environment friendly with low emission of carbon dioxide which is 15% that of steel pipe and without discharge of wasted water, exhausted gas and waste residue which saves 20% energy compare with the traditional steel pipes.

9,High Flexibility

With high toughness and elongation of no less than 350%, the UHMWPE pipe and the connection site will not crack when crust settling which maximally ensure to supply water normally.

Compare with existing plastic pipes, Wear resistant UNMWPE pipe has the most excellent wear resistance which is 4 to 7 times that of Q235 steel pipe and 2.7 times that of wear-resistant steel 16Mn. Therefore it increases pipe flow rate and improves the transmission efficiency of more than 20%. The working life of UHMWPE pipes is more than 3 times that of wear-resistant steel pipe.Wear resistant UHMWPE pipe has great advantages to replace traditional metal pipes in delivering abrasive media.

2,Impact Resistant

Wear resistant UHMWPE pipe is greatly impact resistant which is 5 times that of HDPE pipe, 2 times that of PC pipe and 10 times that of PTFE pipes.With extraordinary impact resistance,UHMWPE pipe can withstand great water hammer impact when starting up pump station.

3,Low Energy Consumption

Wear resistant UHMWPE pipe is self-lubrication and non-adhesive. Its coefficient of friction resistance is 0.009 while that of steel pipe is 0.013. With the same diameter, flow rate of UHMWPE pipe is larger than steel pipe, and with the same flow rate, UHMWPE pipe can save 25% energy.

4,Non-scaling

With roughness of 0.00022 and smooth pipe inner wall, it can efficiently avoid scaling without acid cleaning, which save a lot of maintenance cost.

5,Anti Low Temperature

At the temperature of -70 ℃,UHMWPE pipe can work with normal mechanical performance. It is suitable for water supply and drainage in cold area.

6,High Pressure Resistant

UHMWPE pipe is high pressure resistant and highly flexible. The compressive strength of UHMWPE pipe is 2 times to that of PE100 pipe and 2.5 times to that of PE80. UHMWPE pipes can withstand wide fluctuate of water pressure in the pipeline.

7,Maintenance Free

With characteristics of corrosion resistance, low temperature resistance, non-scaling, no leakage, etc, UHMWPE pipe can work without extra anticorrosive coating, cleaning and maintenance which save more than 95% energy.

8,Environment Friendly

The manufacturing and processing of wear resistant UHMWPE pipe is low carbon and environment friendly with low emission of carbon dioxide which is 15% that of steel pipe and without discharge of wasted water, exhausted gas and waste residue which saves 20% energy compare with the traditional steel pipes.

9,High Flexibility

With high toughness and elongation of no less than 350%, the UHMWPE pipe and the connection site will not crack when crust settling which maximally ensure to supply water normally.

Application of UHMWPE pipe

UHMWPE pipe in dredging project

UHMWPE pipe is high in wear resistance. The flow rate of UHMWPE pipe is more than 4 times that of steel pipe i.e. Working life of UHMWPE pipe is 4 times longer than that of steel pipe, which reduce times of changing pipes during the project and reduce maintenance cost. With low roughness, UHMWPE pipe can save 20% energy which reduce the operation cost. UHMWPE pipe is light in weight and flexible which reduce installation cost and increase comprehensive benefit.

UHMWPE pipe in mining and metallurgy

Coke, mining powder,pulp and slag from mining and metallurgy is quite abrasive to pipelines. Traditional steel pipe can only use for 6 or 12 months for transmission of above media and need to turn 90 degrees every half year. Meantime, UHMWPE pipe has extraordinary wear resistance which greatly reduces damage of pipes from abrasion and its working life is more than 4 times that of traditional steel pipe. With good impact resistance and high flexibility,UHMWPE pipe can withstand impact from external force and diastrophism. Wear resistant UHMWPE pipe is better alternative as transmission pipe for mining and metallurgy.

UHMWPE pipe in transmission of coal ash in thermal power plant

For hydraulic ash-sluicing system of thermal power plant, the problem of scaling in inner pipe wall is quite prevalent. especially within 100 meters of the entrance, scaling and corrosion are more serious. Ash-sluicing pipe is seriously worn besides scaling.Within two years there will be serious leakage especially at the bend sites. Wear resistant UHMWPE pipe is self-lubricating and non scaling. With excellent wear resistance and corrosion resistance, it has longer working life and significantly save maintenance costs which greatly increases benefits.

UHMWPE pipe in pneumatic transmission

With low friction resistance, high self lubrication and high wear resistance, UHMWPE pipe can be widely used in field of pneumatic transmission of material which effectively reducing abrasion and corrosion and lowering energy consumption.

UHMWPE pipe is high in wear resistance. The flow rate of UHMWPE pipe is more than 4 times that of steel pipe i.e. Working life of UHMWPE pipe is 4 times longer than that of steel pipe, which reduce times of changing pipes during the project and reduce maintenance cost. With low roughness, UHMWPE pipe can save 20% energy which reduce the operation cost. UHMWPE pipe is light in weight and flexible which reduce installation cost and increase comprehensive benefit.

UHMWPE pipe in mining and metallurgy

Coke, mining powder,pulp and slag from mining and metallurgy is quite abrasive to pipelines. Traditional steel pipe can only use for 6 or 12 months for transmission of above media and need to turn 90 degrees every half year. Meantime, UHMWPE pipe has extraordinary wear resistance which greatly reduces damage of pipes from abrasion and its working life is more than 4 times that of traditional steel pipe. With good impact resistance and high flexibility,UHMWPE pipe can withstand impact from external force and diastrophism. Wear resistant UHMWPE pipe is better alternative as transmission pipe for mining and metallurgy.

UHMWPE pipe in transmission of coal ash in thermal power plant

For hydraulic ash-sluicing system of thermal power plant, the problem of scaling in inner pipe wall is quite prevalent. especially within 100 meters of the entrance, scaling and corrosion are more serious. Ash-sluicing pipe is seriously worn besides scaling.Within two years there will be serious leakage especially at the bend sites. Wear resistant UHMWPE pipe is self-lubricating and non scaling. With excellent wear resistance and corrosion resistance, it has longer working life and significantly save maintenance costs which greatly increases benefits.

UHMWPE pipe in pneumatic transmission

With low friction resistance, high self lubrication and high wear resistance, UHMWPE pipe can be widely used in field of pneumatic transmission of material which effectively reducing abrasion and corrosion and lowering energy consumption.

Packing & Delivery

SEA WORTH PACKING

Hot Searches