Heating ring material:Cast aluminum

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OCTTECH

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

25000*2000*2500MM

-

Power (kW):

-

120

-

Weight:

-

2500 KG

-

Keywords:

-

corrugated hose making machine

-

Final product:

-

PE HDPE PVC

-

Material:

-

PE PVC granules

-

Automatic Grade:

-

Fully Automaitc

-

Inverter:

-

ABB Brand

-

Color:

-

Customized Color

-

Screw type:

-

Singe screw

-

Motor brand:

-

SIENEMS BEIDE

-

Processing Type:

-

Corrugated pipe Extrusion Machine

-

Application Field:

-

Construction Material

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

35 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OCTTECH

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

25000*2000*2500MM

-

Power (kW):

-

120

-

Weight:

-

2500 KG

-

Keywords:

-

corrugated hose making machine

-

Final product:

-

PE HDPE PVC

-

Material:

-

PE PVC granules

-

Automatic Grade:

-

Fully Automaitc

-

Inverter:

-

ABB Brand

-

Color:

-

Customized Color

-

Screw type:

-

Singe screw

-

Motor brand:

-

SIENEMS BEIDE

-

Processing Type:

-

Corrugated pipe Extrusion Machine

-

Application Field:

-

Construction Material

Products Description

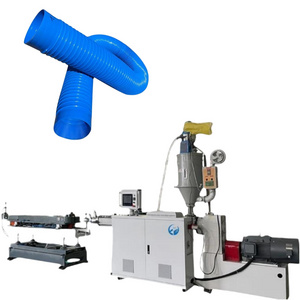

1.This extrusion line can be used to produce corrugated pipes of PE,PP,PVC.

2.Plastic single wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc.

3.The pipes made by our machines can be used in fields, such as auto wire, electric thread passing pipes, circuit of machine tool,protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc

2.Plastic single wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc.

3.The pipes made by our machines can be used in fields, such as auto wire, electric thread passing pipes, circuit of machine tool,protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc

Machine Working Flow

Raw material(pellets) + master batches→mixer→vacuum feeding →hopper and dryer →single screw extruder→extrusion mould→corrugated forming machine→double station winder→finished product inspecting &packing

Product Paramenters

|

Pipe size(mm)

|

4.5-9

|

9-32

|

16-63

|

||

|

Extruder

|

SJ30/30

|

SJ45/30

|

SJ65/30

|

||

|

Capacity(kg/h)

|

10

|

40

|

80

|

||

|

Main Motor(Kw)

|

2.2

|

11

|

18.5

|

||

|

Forming Machine(Kw)

|

1.1

|

1.5

|

2.2

|

||

|

Mold Block (Pair)

|

40

|

44

|

44

|

||

|

Cooling Method

|

Water/Air cooling

|

|

|

||

|

Production Speed(m/min)

|

8-16

|

6-14

|

6-12

|

||

Product Details

MAIN EXTRUDER

Material of screw and machine barrel:38CrMoALA

Extruder mould:

Basic mould:40Cr treatment

Die mouth,mandril:40Cr

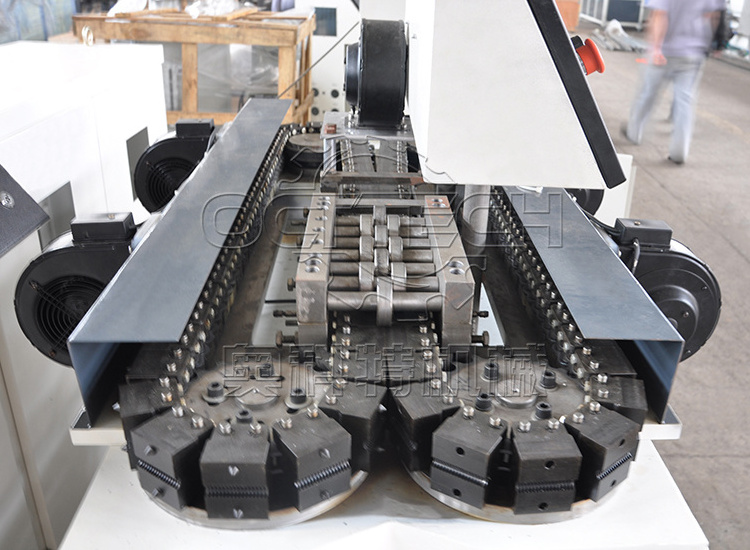

Corrugated forming mould

CORRUGATED FORMING MACHINE

Material of moulding board:Cast iron, processing

Hauling speed:1-15m/min

Speed controlled by Inverter

Hauling speed:1-15m/min

Speed controlled by Inverter

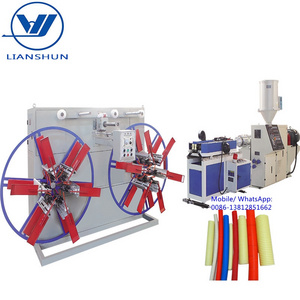

WINDER MACHINE

Double station or single station winder for

choice

Torque motor force

choice

Torque motor force

Hot Searches