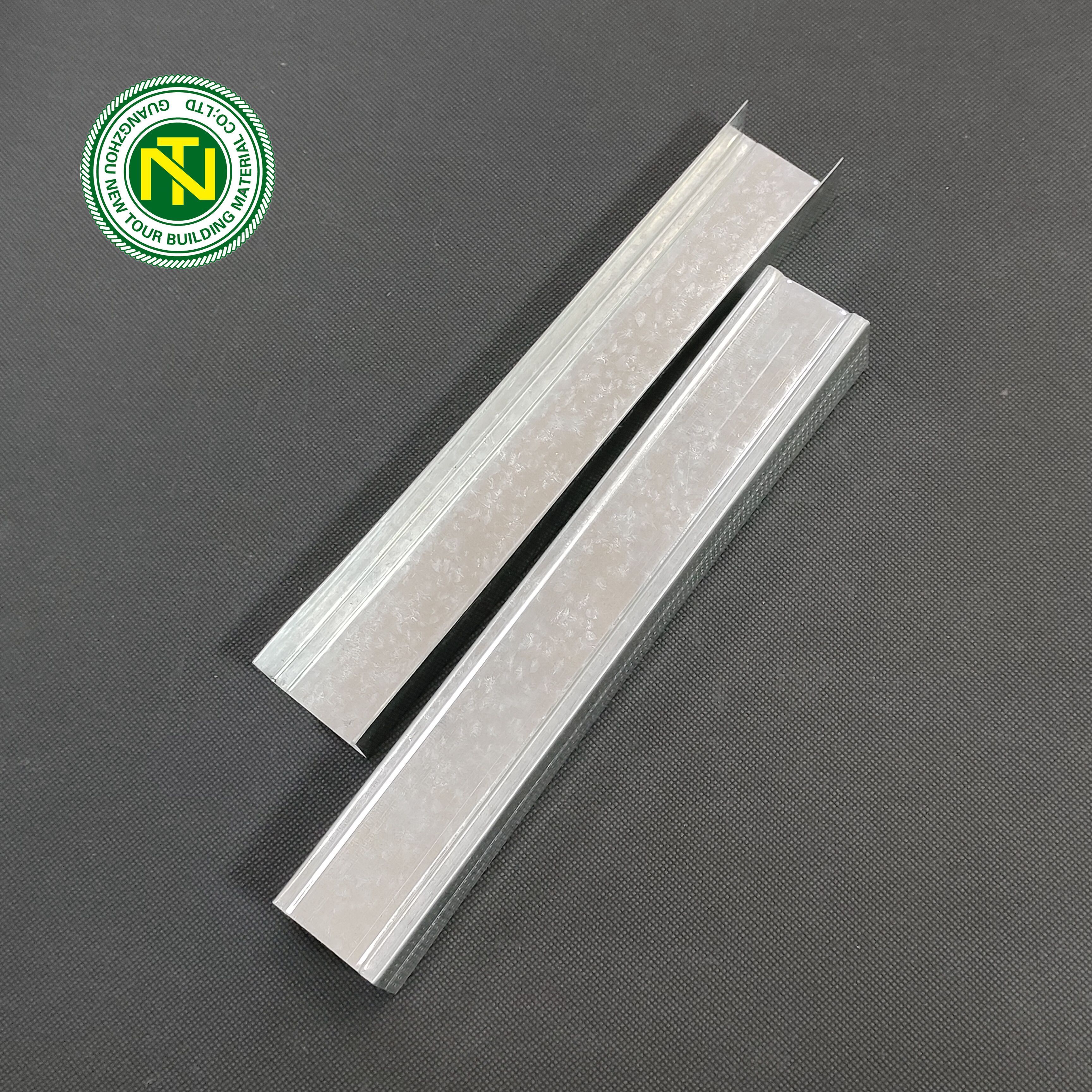

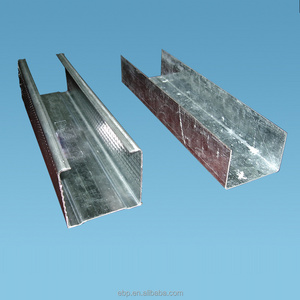

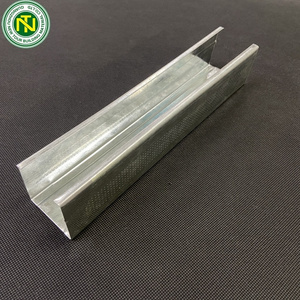

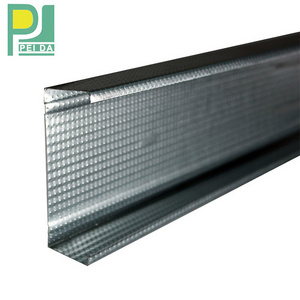

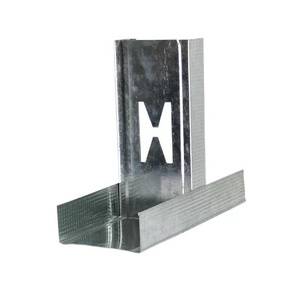

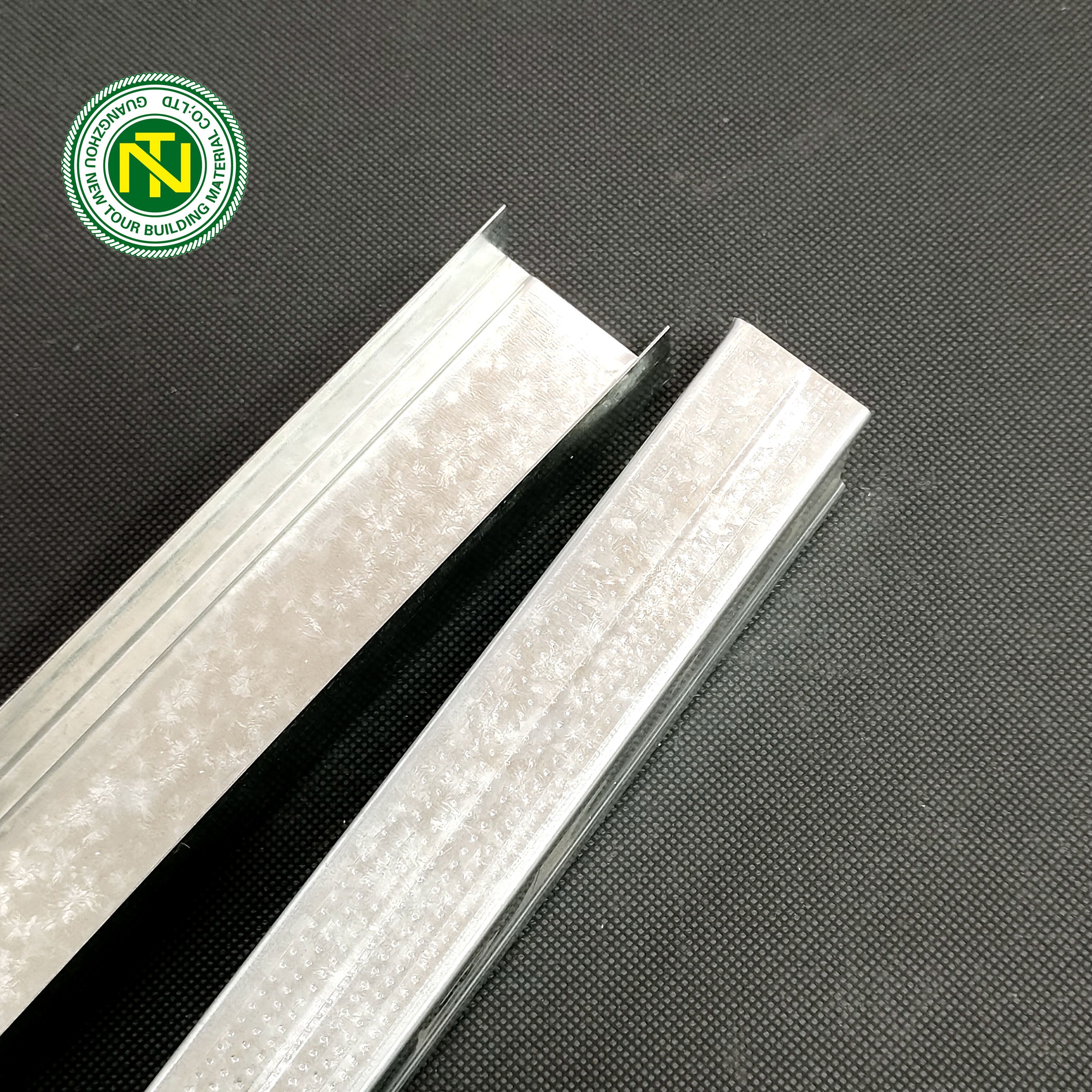

1. Galvanized Metal Frame

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with laterally supporting keel installed.

2. Board Material Package Fixed

a.Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b.Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250 mm with screws sinking 0.5 mm under the board face.

c.The expansion seam of about 4 mm between boards should be kept.

d.The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking.

e.Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Weight:

-

0.60

-

Chemical Composition:

-

Galvanized Sheet

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NEW TOUR

-

Model Number:

-

u channel

-

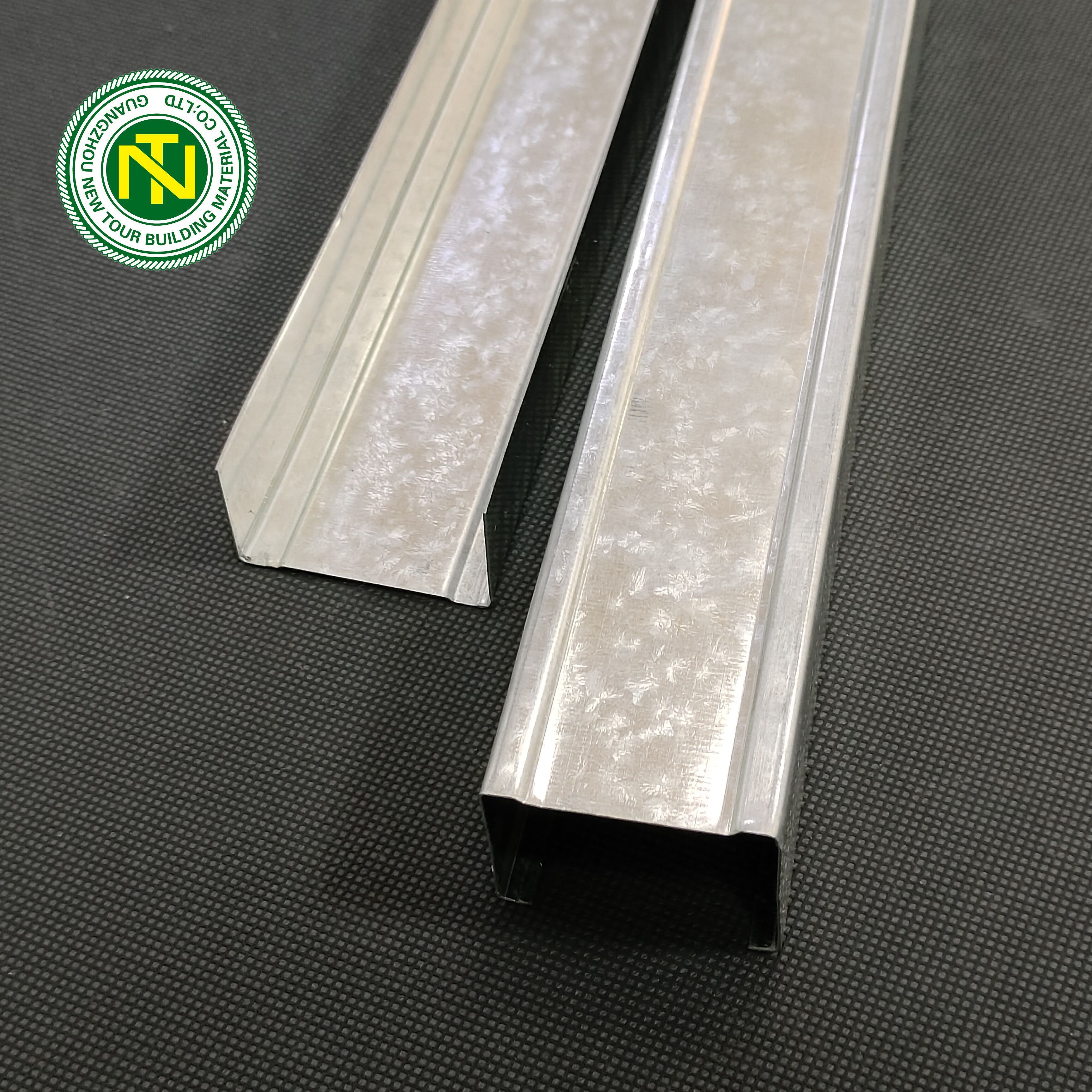

Type:

-

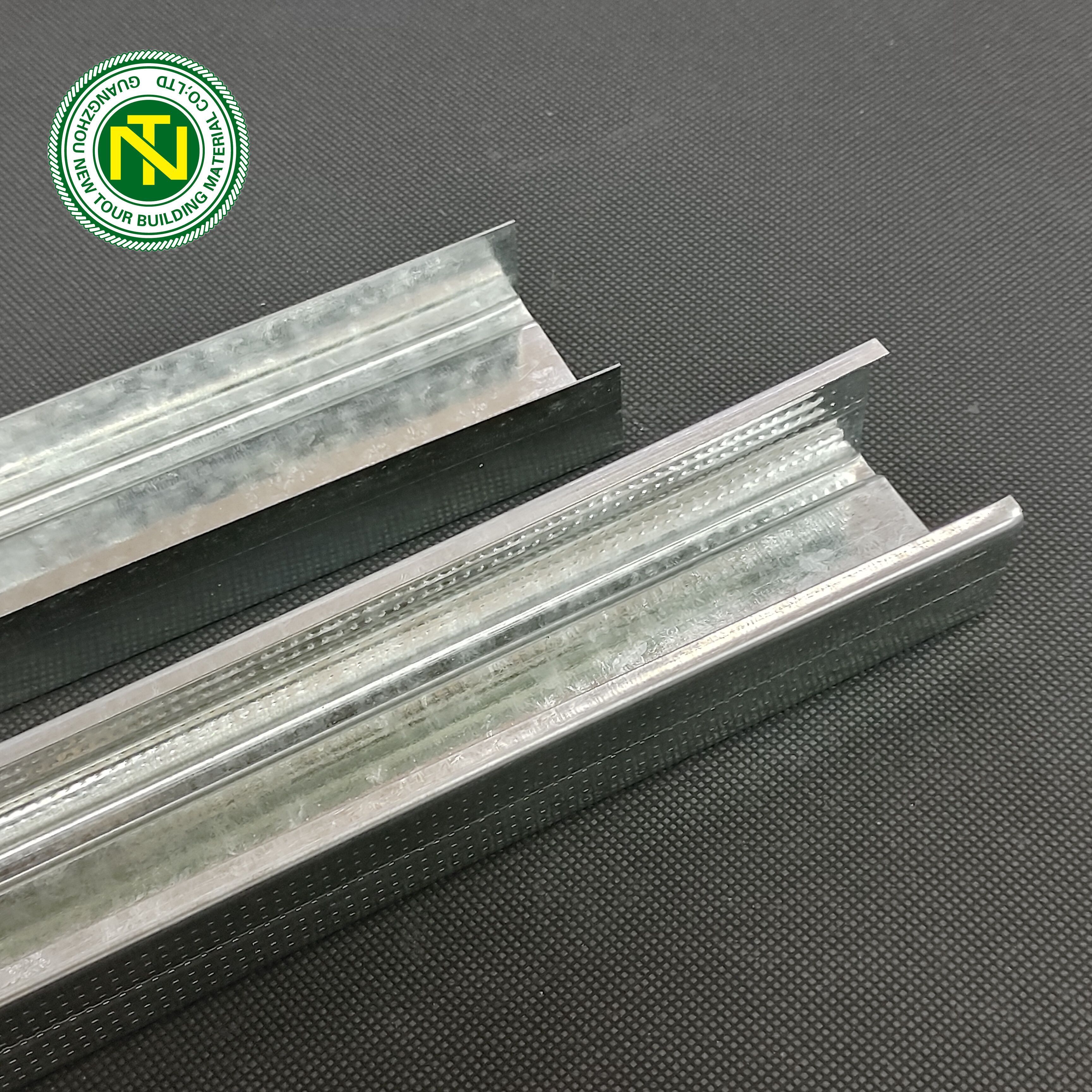

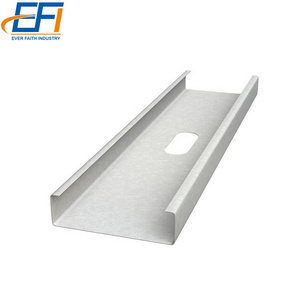

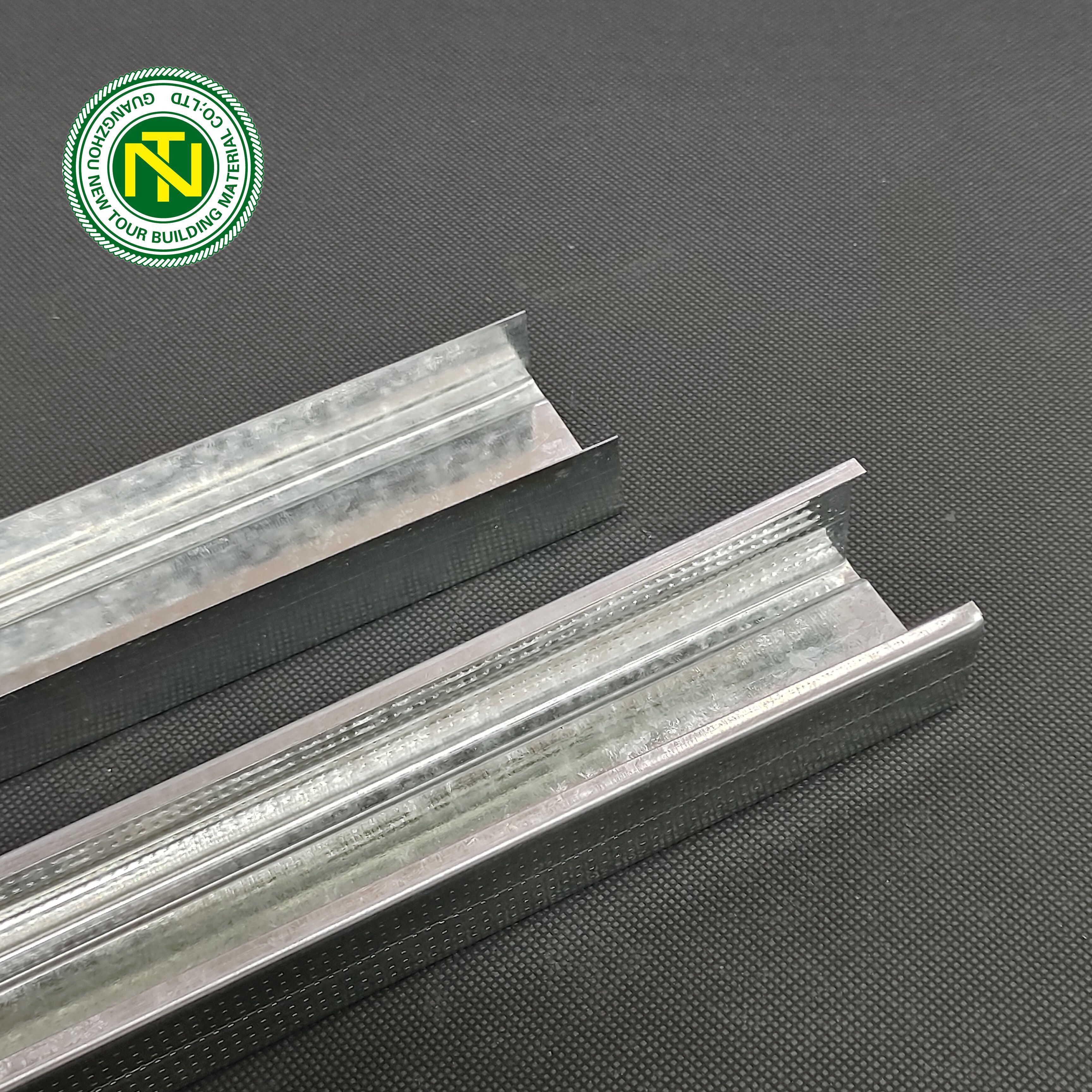

C channel, U channel

-

Function:

-

drywall ceiling tile

-

Material:

-

Galvanized Steel

-

Zine coat:

-

60~180g/m2

-

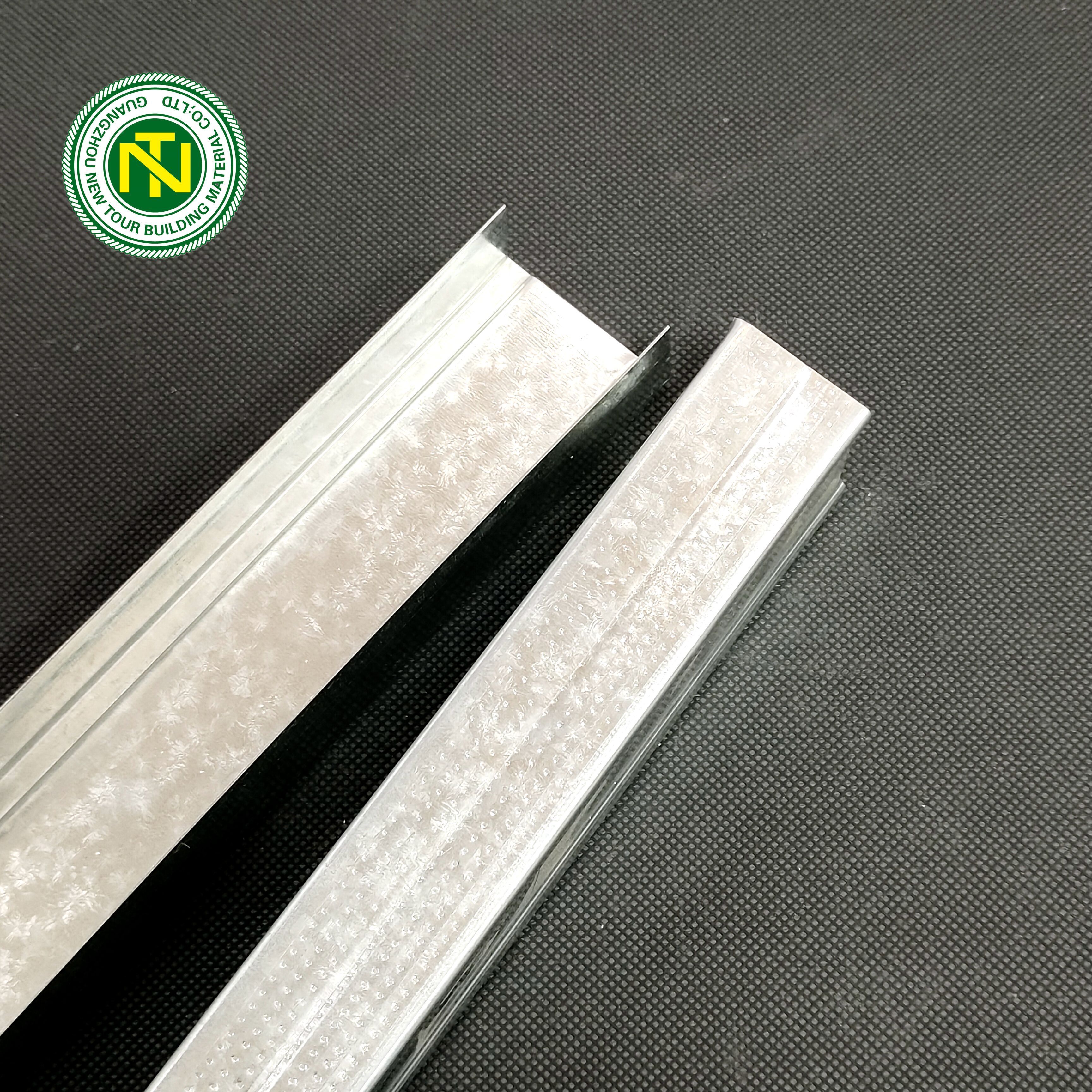

Length:

-

3000 mm or customized

-

Height:

-

25mm,30mm,35mm,40mm,45mm

-

Width:

-

50mm,60mm,70mm,75mm,90mm,

-

Light weight:

-

Relieve the burden of building structural load-bearing

-

Thickness:

-

0.45 , 0.5 , 0.6 ,0.8,0.9MM

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

Other, NONE

-

Project Solution Capability:

-

NONE, Others

-

Application:

-

Office Building

-

Design Style:

-

Modern

-

Weight:

-

0.60

-

Chemical Composition:

-

Galvanized Sheet

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NEW TOUR

-

Model Number:

-

u channel

-

Type:

-

C channel, U channel

-

Function:

-

drywall ceiling tile

-

Material:

-

Galvanized Steel

-

Zine coat:

-

60~180g/m2

-

Length:

-

3000 mm or customized

-

Height:

-

25mm,30mm,35mm,40mm,45mm

-

Width:

-

50mm,60mm,70mm,75mm,90mm,

-

Light weight:

-

Relieve the burden of building structural load-bearing

-

Thickness:

-

0.45 , 0.5 , 0.6 ,0.8,0.9MM

Product Description

Main Characteristic:

1.Galvanized Zinc coating will protect the channel from being rust;

2.Flexibility of application makes each ceiling tile/plasterboard easily installed and disconnected;

3.Size adjustability can easier to match your request;

4.High quality leads longer life span & higher strength;

5.Better function of dealing with both high tensile stress and blending stress.

6. Easy and fast for installation,time-saving.

1.Galvanized Zinc coating will protect the channel from being rust;

2.Flexibility of application makes each ceiling tile/plasterboard easily installed and disconnected;

3.Size adjustability can easier to match your request;

4.High quality leads longer life span & higher strength;

5.Better function of dealing with both high tensile stress and blending stress.

6. Easy and fast for installation,time-saving.

Specification

|

Metal Stud

|

|

|

|

|||

|

Width(mm)

|

Height(mm)

|

Length(mm)

|

Thickness(mm)

|

|||

|

50

|

32

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

75

|

30

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

75

|

40

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

100

|

50

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

Above all are our normal size,we can accept customized size,welcome to contact

|

|

|

|

|||

|

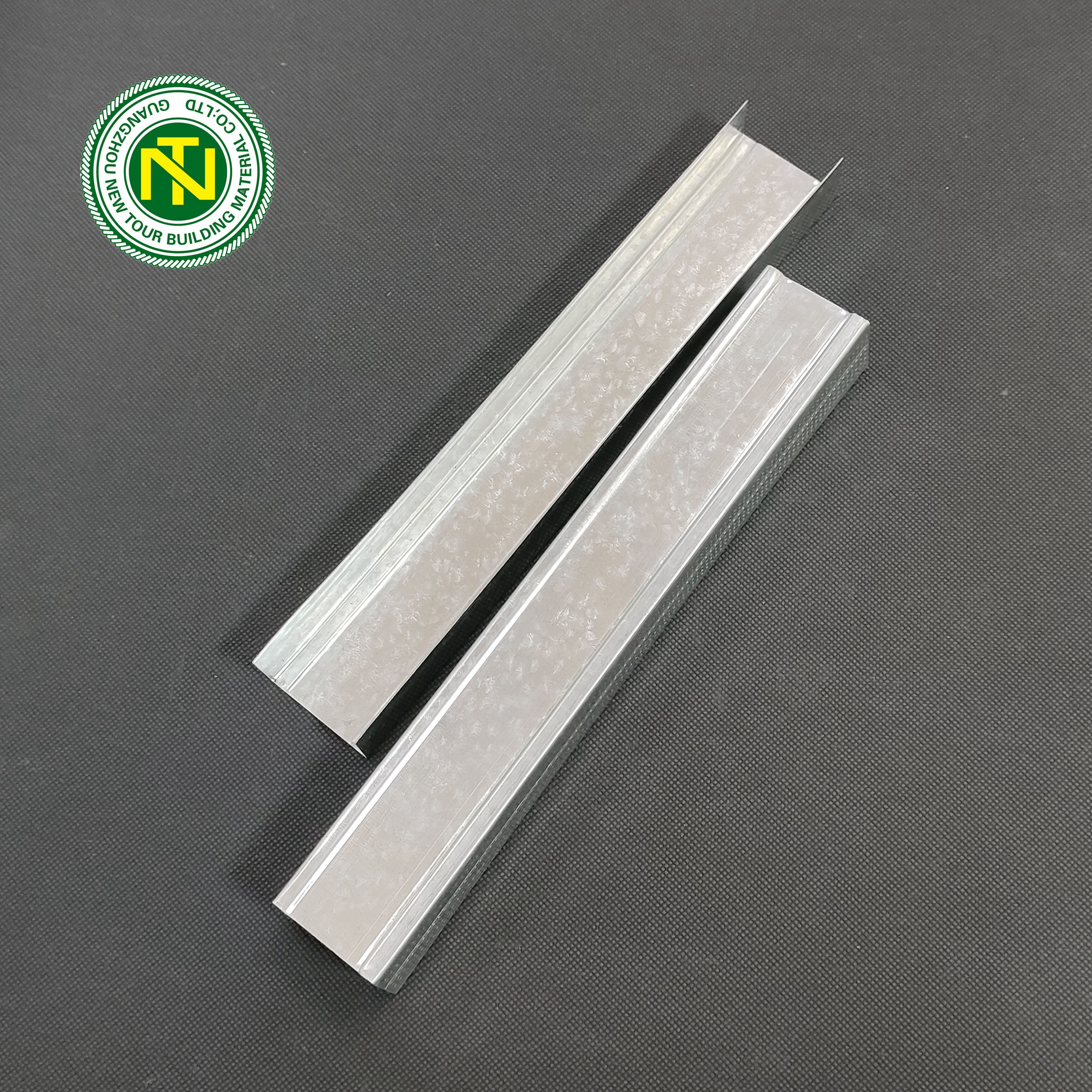

Metal Track

|

|

|

|

|||

|

Width(mm)

|

Height(mm)

|

Length(mm)

|

Thickness(mm)

|

|||

|

50

|

22

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

75

|

22

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

75

|

30

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

100

|

40

|

3000

|

0.4/0.45/0.5/0.6/0.8/0.9

|

|||

|

Above all are our normal size,we can accept customized size,welcome to contact

|

|

|

|

|||

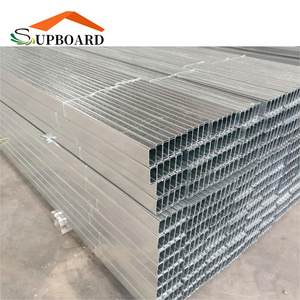

Packing & Delivery

Packaging Details: loose bundle package each 8pcs or 10pcs,12pcs,20pcs, etc.

Delivery Time: Shipped in 10 days after payment

Delivery Time: Shipped in 10 days after payment

Application

How to install it

Production Line

Hot Searches