- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/415V/440V or customer

-

Power:

-

100-150KW customized

-

Dimension(L*W*H):

-

2250*2160*1760mm

-

Weight (KG):

-

6800

-

Product name:

-

Foundry Casting Sand Core Shooter

-

Application:

-

Die Casting Machine

-

Advantage:

-

Small Energy Consumption

-

Die thickness(min~max):

-

110~220~300mm

-

Usage:

-

Sand Moulding Making

-

Material:

-

Coated Resin Sand

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Foundry Core Shooting Machine

-

Brand Name:

-

TZZJ

-

Voltage:

-

220V/380V/415V/440V or customer

-

Power:

-

100-150KW customized

-

Dimension(L*W*H):

-

2250*2160*1760mm

-

Weight (KG):

-

6800

-

Product name:

-

Foundry Casting Sand Core Shooter

-

Application:

-

Die Casting Machine

-

Advantage:

-

Small Energy Consumption

-

Die thickness(min~max):

-

110~220~300mm

-

Usage:

-

Sand Moulding Making

-

Material:

-

Coated Resin Sand

Product Display&Details

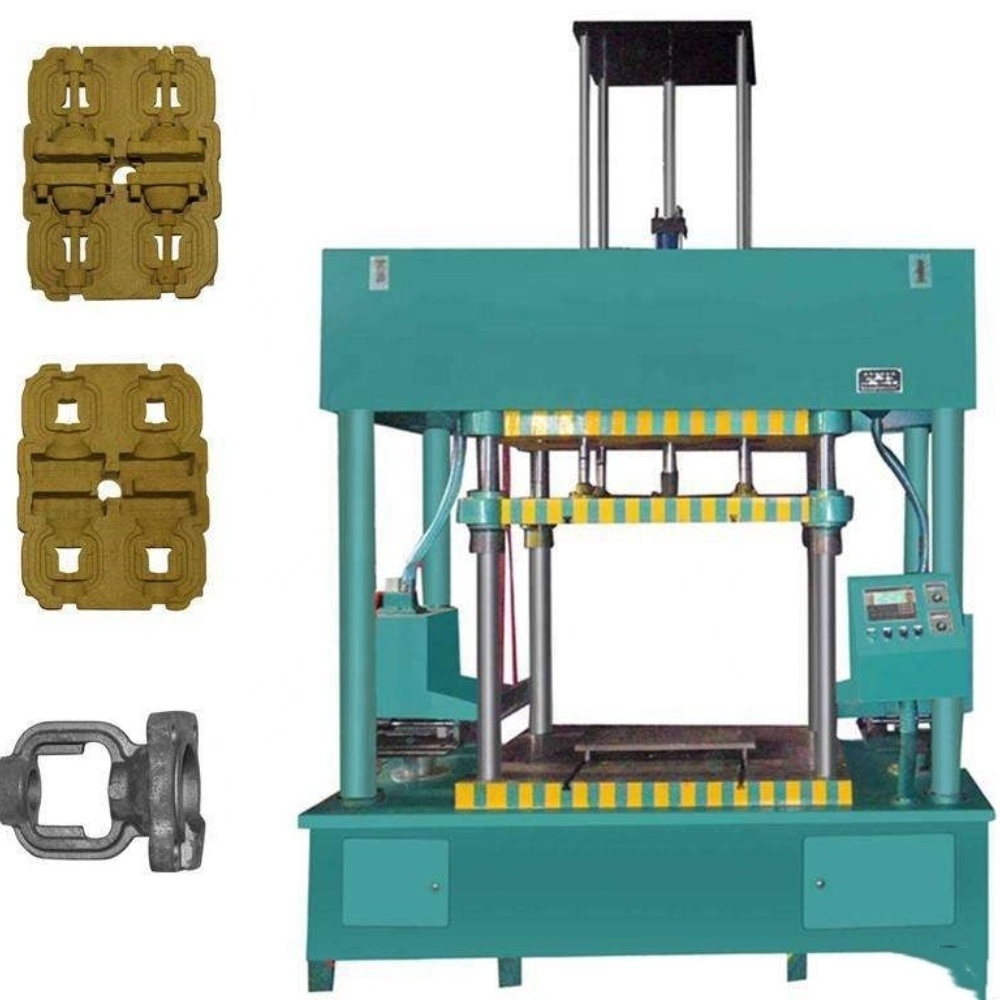

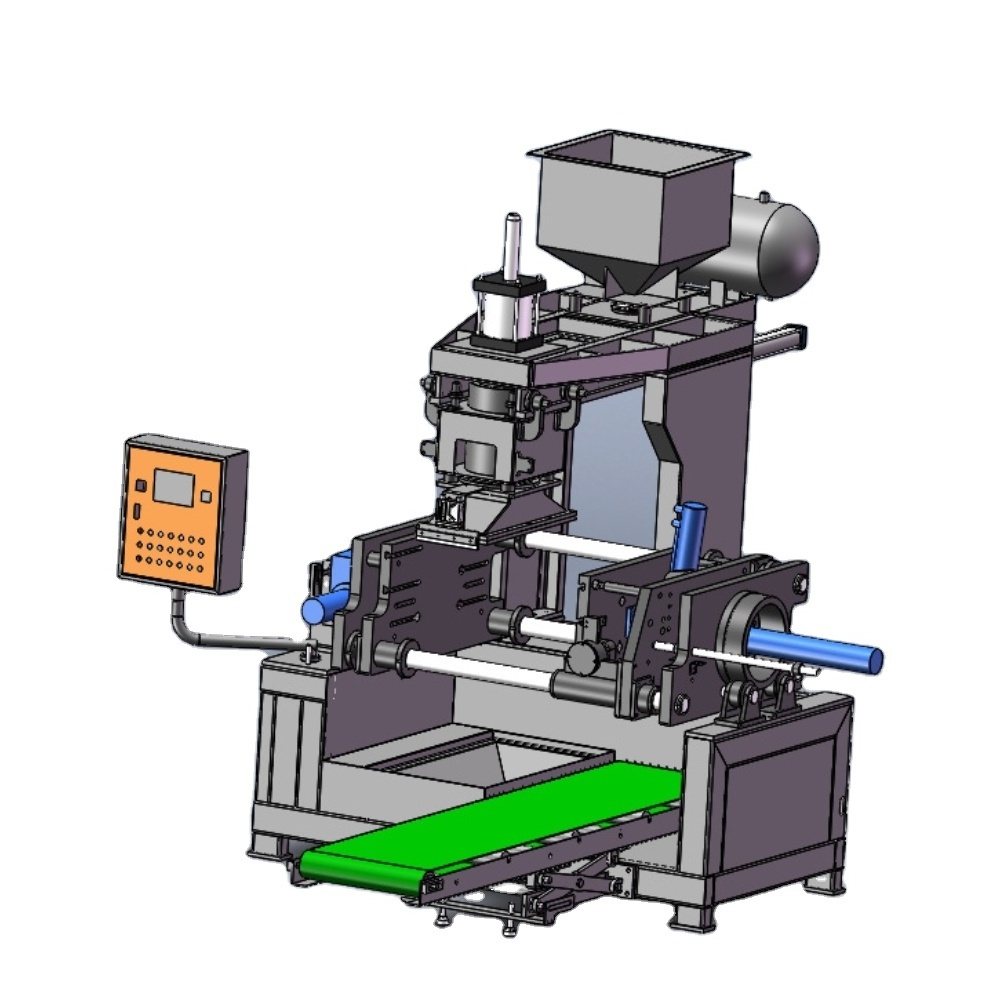

Coated sand core shooting machine

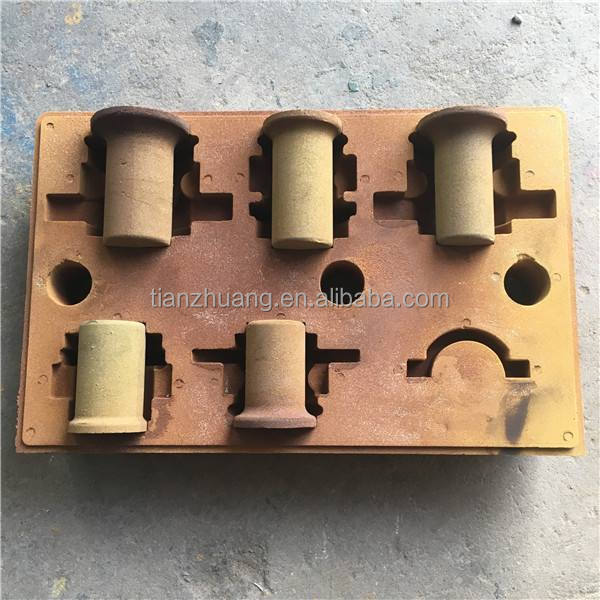

is a kind of machine which uses coated sand as raw material and hot core box principle to make coated sand mold. The raw material of film sand core for core shooting machine is phenolic resin sand. It has the characteristics of high production efficiency, accurate size, smooth appearance, and can produce complex inner cavity castings.

The double-head core-shooting machine can meet the needs of shell shape and shell core, PLC programmable control, adjustable process parameters, automatic mold temperature control, and can mass-produce small and medium-sized castings with responsible shapes.

The production material of double-head core-shooting machine is coated sand. The sand is instantly injected into the cavity by high-pressure airflow, and the mold is heated (electricity or gas) to 180-240 ℃ to solidify and form, and can make sand mold, shell mold, one finished product The molding cycle is generally 30-240 seconds (depending on the size of the sand mold). The surface of the product is smooth, and it can be used after molding, shortening the core making time and technological process, and production.

The water-cooled shooter in the core shooter is integral. If it is to be transformed, it is to be split into two parts, that is, the water-cooled shooter is divided into two parts: the shooter and the cooling water flow. In this way, the scope of use of common parts can be expanded, the cost will be reduced a lot, and the use will be more convenient.

double-head core-shooting machine specific working principle

The resin sand shell core method is a meticulous core making process. It fills the core sand containing phenolic resin (referred to as shell core sand) into the heated metal core box for a certain time (5~15s), The resin in the shell core sand near the wall of the core box is melted to bond the sand grains together, and a shell layer in a plastic state with a certain thickness is formed along the inner cavity wall of the core box. After pouring out the excess core sand, continue to heat for a certain time (30~90s), open the core box and push out the shell core, that is, the hollow thin shell sand core with a small wall thickness (only 5~12mm). It only takes 1~2min to make a sand core.

Product features:

1. High production efficiency: The working process of the hot core box core shooting machine is completed at the same time as the sand compaction, and the hot core box is immediately hardened. The production cycle of sand cores for casting is only ten to tens of seconds.

2. Good quality of sand core: can shoot any complex sand core, accurate size, smooth surface, reduce casting processing allowance.

3. Many auxiliary equipment and tools for core making can be omitted, such as core drying furnace, dryer, core bone, wax wire, etc.

4. Reduce labor intensity, flexible and convenient operation, the use of electric heating, temperature can be automatically controlled, the workplace is easy to keep clean, creating conditions for the mechanization and automation of the core process.

Daily maintenance measures of core shooter:

1. Check whether the gas cylinders, gas paths and valves are leaking, and remove them in time.

2. During work, clean the contact surfaces of moving parts at any time. Such as guide bushes, guide posts, etc.

3. Always check whether the fastening bolts and nuts of each component are loose, and tighten them in time.

4. Clean the equipment every day after get off work, and completely clean the inside and outside once a week.

5. Keep the electrical cabinet and operating surface clean. Close the door tightly after non-maintenance or set times.

Product Paramenters

Usage & Application scope

Z94 hot-core box core shooter/core shooting machine, is a four pillars open-close structure, auto & manual operation type core making equipment, which is suitable for making sand cores (less than 3.2kg). The working principle of the machine is shooting dried resin sand/coated sand into heated core box and harden to a certain thickness very fast, take out, then can get sand cores with smooth surface and precision size.

|

Item

|

Z9404

|

Z9406

|

Z9407

|

||

|

Template size(mm)

|

650*450

|

650*450

|

700*400

|

||

|

Max weight of shooting(kg)

|

27

|

25

|

25

|

||

|

Size of open and close template(mm)

|

Max700,Min330

|

Max700,Min330

|

Max700,Min330

|

||

|

Productivity(s)

|

60-80s

|

80s

|

80s

|

||

|

System pressure(Mpa)

|

0.6

|

0.6

|

0.6

|

||

|

Shooting pressure(Mpa)

|

0.4

|

0.4

|

0.4

|

||

|

Heating mode

|

Electrical heating

|

|

|

||

|

Nomber of work-box

|

1 set

|

2 set

|

2 set

|

||

|

Sand delivery mode

|

Pneumatic convey/bucket elevator

|

|

|

||

Product Show

Packing&Shipping

Hot Searches