- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 220v/110v

-

Dimension(L*W*H):

-

650*300*540mm

-

Weight:

-

23 KG

-

Power:

-

0.45kW

-

Product name:

-

Water Chiller

-

Application:

-

Cooling Equipment

-

Function:

-

Chilled Water

Quick Details

-

Condition:

-

New

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KH

-

Voltage:

-

220V, 220v/110v

-

Dimension(L*W*H):

-

650*300*540mm

-

Weight:

-

23 KG

-

Power:

-

0.45kW

-

Product name:

-

Water Chiller

-

Application:

-

Cooling Equipment

-

Function:

-

Chilled Water

Products Description

Product Details

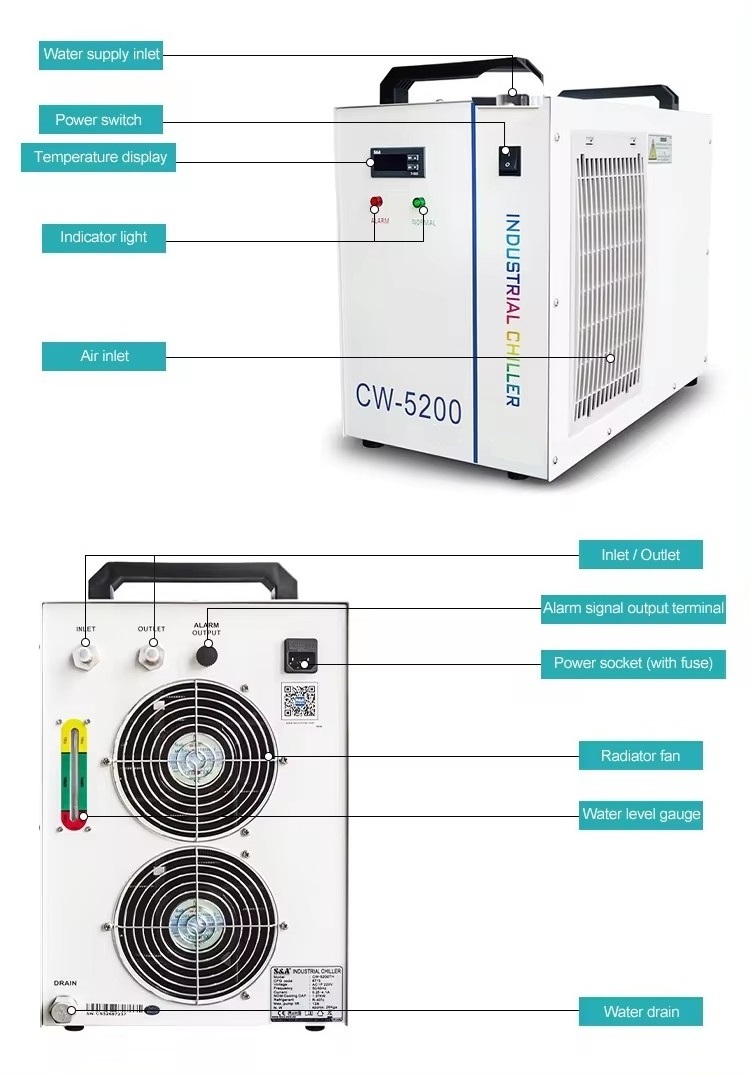

Temperature Controller

Fan

Water Inlet And Outlet

Parameter Details

|

Model

|

CW-3000

|

CW-5000

|

CW-5200

|

|

Voltage

|

AC 110V/ 220-240V

|

AC 110V/ 220-240V

|

AC 110V/ 220-240V

|

|

Frequency

|

50/60Hz

|

50/60Hz

|

50/60Hz

|

|

Current

|

0.4~1A

|

0.4~5.3A

|

0.5~8.9A

|

|

Machine Power

|

0.1kW

|

0.45kW

|

0.75kW

|

|

Max.lift

|

10M

|

10M

|

12M

|

|

Max.flow

|

10L/min.

|

10L/min.

|

13L/min.

|

|

Protection

|

Flow Alarm

|

Flow Alarm

|

Flow Alarm

|

|

Tank Capacity

|

9L

|

|

|

|

Inlet & Outlet

|

OD 10mm Barbed Connector

|

OD 10mm Barbed Connector

|

OD 10mm Barbed Connector

|

|

N.W.

|

9.5kg

|

22kg

|

23kg

|

|

G.W.

|

12kg

|

24.5kg

|

29kg

|

|

Dimension

|

470mm*270*370mm (L*W*H)

|

630*290*500mm (L*W*H)

|

650*300*540mm (L*W*H)

|

|

Package Dimension

|

590*380*470mm (L*W*H)

|

700*430*580mm (L*W*H)

|

720*440*620mm (L*W*H)

|

CW-3000, CW-5000,CW-5200 Series are professional cooling machines referring to international, advanced thermolysis cooling system designed,suitable for small water-cooled cooling devices requested machinery. The Industrial Water Chiller has a patent Certificate, CE and RoHS Certificate. It has been sold largely to Europe, South America, Asia and other markets.

It is designed for cooling the one CO2 glass laser tube under 130W/150W of the laser engraving and cutting machine.

Under normal circumstance, the new intelligent temperature controller does not need to adjust the controlling parameters.

It will self-adjust controlling parameters according to room temperature to meet cooling demands.

Application

Mainly used to have the heat generated during the laser device working that gone through the refrigerating cycle in compressor

refrigeration system and eventually transferred to the air. The water temperature is able to be adjusted. There are 2

specifications as 1 water outlet / inlet and dual water outlet / inlet, applicable to cool single laser glass tube.

Economic cooling equipment, easy to install and operate, compact and easily movable.

Our industrial water chillers are popular for its 2 temperature control modes as constant temperature and intelligent temperature

control. Under intelligent mode, the water temperature is adjusted according to ambient temperature. With this 1 key solution,

customers no longer need to worry about water temperature adjustment of seasonal changes.

How to use

* Fill the water tank with purified water.

* Connect the water inlet of the water tank to the water outlet of the laser machine and connect the water outlet of the water

tank to the water inlet of the laser machine.

Installation steps

A. Open the package to check if the machine is intact and all the necessary accessories are completed.

B. Open the injection port to feed cooling water.

Observe water level gauge while adding water slowly, be careful not to have water overflowed! For the cooling of carbon steel

equipment, water should be added with an appropriate amount of anti-corrosion agentia. Working in cold north area, it’s better to

use noncorrosive antifreeze fluid.

C. According to system conditions, please well connect water inlet and outlet pipe.

D. Plug in, turn on the power switch. (Do not start up without water in the tank!)

(1) Circulation pump of the chiller starts working. Operating for the first time may produce bubbles in the pipe, which

occasionally leads to flow alarming. In such case, it will go back to normal after running for a few minutes.

(2) After the first boot, please immediately check whether the water pipe leaks.

(3) Power switched on, if the water temperature is below the set figure, it is normal that fans and other components of the

machine do not work. The temperature controller will automatically control the working conditions of the compressor, magnetic

valve, fans and other parts based on the set controlling parameters.

(4) As it takes a longer time to start the compressor and other components, the time you take might range from seconds to minutes,

please do not turn the power off and on again frequently.

E. Check the water level in the water tank.

The first startup of the new chiller empties the air in the water pipe, leading slightly water level decline. In order to keep the

water level in the green area, it’s allowed to replenish adequate water. Please observe and record the current water level and

inspect it again after the chiller has been running for a period of time, if the water level drops obviously, please re-inspect

the water pipeline leakage.

F. Adjust parameters of temperature controller.

CW-5200 series use an intelligent thermostat. Normally users do not need to adjust it. If it's really necessary, please refer to

"Operating status and parameters adjustment."

Notice

* Cooling water must be kept empty when cooling machine has been not in use for long or in transport.

* It is strictly forbidden to plug and run the cooler without feeding water.

* Cooler should be placed in a well-ventilated, dry environment away from heat sources. Please keep at least 30cm from

obstructions to the air outlet which is in the back of the cooler, and leave at least 10cm between obstructions and air inlets

of two sides.

* To protect laser tubes , the radiator fan of cooler will suspend to work when water temperature is too low , and it will

restart to run when water temperature rises back to accceptable range.

* To ensure good heat dissipating, please open the lid to clean the dirt regularly.

* Working in cold north area, it is better to use noncorrosive antifreeze fluid.

Alarm Function

E1- Over high room temperature

E2- Over high water temperature

E3- Over low water temperature

E4- Room temperature sensor failure

E5- Water temperature sensor failure

Remark:

When alarm occurs, the error code and the temperature will be alternately displayed.

In alarming state, the alarm sound could be suspended by pressing any button, but the alarm display

remains until the alarm condition is eliminated.

Flow alarm and output ports:

In order to guarantee that the equipment will not be damaged when cooling water circulation is out of control, CW-5200series chillers possesses an unique low flow alarm protection.

The flow alarm is connected to the normally open relay and normally closed relay contacts, requiring operating current less than 5A, working voltage less than 300V.

It is designed for cooling the one CO2 glass laser tube under 130W/150W of the laser engraving and cutting machine.

Under normal circumstance, the new intelligent temperature controller does not need to adjust the controlling parameters.

It will self-adjust controlling parameters according to room temperature to meet cooling demands.

Application

Mainly used to have the heat generated during the laser device working that gone through the refrigerating cycle in compressor

refrigeration system and eventually transferred to the air. The water temperature is able to be adjusted. There are 2

specifications as 1 water outlet / inlet and dual water outlet / inlet, applicable to cool single laser glass tube.

Economic cooling equipment, easy to install and operate, compact and easily movable.

Our industrial water chillers are popular for its 2 temperature control modes as constant temperature and intelligent temperature

control. Under intelligent mode, the water temperature is adjusted according to ambient temperature. With this 1 key solution,

customers no longer need to worry about water temperature adjustment of seasonal changes.

How to use

* Fill the water tank with purified water.

* Connect the water inlet of the water tank to the water outlet of the laser machine and connect the water outlet of the water

tank to the water inlet of the laser machine.

Installation steps

A. Open the package to check if the machine is intact and all the necessary accessories are completed.

B. Open the injection port to feed cooling water.

Observe water level gauge while adding water slowly, be careful not to have water overflowed! For the cooling of carbon steel

equipment, water should be added with an appropriate amount of anti-corrosion agentia. Working in cold north area, it’s better to

use noncorrosive antifreeze fluid.

C. According to system conditions, please well connect water inlet and outlet pipe.

D. Plug in, turn on the power switch. (Do not start up without water in the tank!)

(1) Circulation pump of the chiller starts working. Operating for the first time may produce bubbles in the pipe, which

occasionally leads to flow alarming. In such case, it will go back to normal after running for a few minutes.

(2) After the first boot, please immediately check whether the water pipe leaks.

(3) Power switched on, if the water temperature is below the set figure, it is normal that fans and other components of the

machine do not work. The temperature controller will automatically control the working conditions of the compressor, magnetic

valve, fans and other parts based on the set controlling parameters.

(4) As it takes a longer time to start the compressor and other components, the time you take might range from seconds to minutes,

please do not turn the power off and on again frequently.

E. Check the water level in the water tank.

The first startup of the new chiller empties the air in the water pipe, leading slightly water level decline. In order to keep the

water level in the green area, it’s allowed to replenish adequate water. Please observe and record the current water level and

inspect it again after the chiller has been running for a period of time, if the water level drops obviously, please re-inspect

the water pipeline leakage.

F. Adjust parameters of temperature controller.

CW-5200 series use an intelligent thermostat. Normally users do not need to adjust it. If it's really necessary, please refer to

"Operating status and parameters adjustment."

Notice

* Cooling water must be kept empty when cooling machine has been not in use for long or in transport.

* It is strictly forbidden to plug and run the cooler without feeding water.

* Cooler should be placed in a well-ventilated, dry environment away from heat sources. Please keep at least 30cm from

obstructions to the air outlet which is in the back of the cooler, and leave at least 10cm between obstructions and air inlets

of two sides.

* To protect laser tubes , the radiator fan of cooler will suspend to work when water temperature is too low , and it will

restart to run when water temperature rises back to accceptable range.

* To ensure good heat dissipating, please open the lid to clean the dirt regularly.

* Working in cold north area, it is better to use noncorrosive antifreeze fluid.

Alarm Function

E1- Over high room temperature

E2- Over high water temperature

E3- Over low water temperature

E4- Room temperature sensor failure

E5- Water temperature sensor failure

Remark:

When alarm occurs, the error code and the temperature will be alternately displayed.

In alarming state, the alarm sound could be suspended by pressing any button, but the alarm display

remains until the alarm condition is eliminated.

Flow alarm and output ports:

In order to guarantee that the equipment will not be damaged when cooling water circulation is out of control, CW-5200series chillers possesses an unique low flow alarm protection.

The flow alarm is connected to the normally open relay and normally closed relay contacts, requiring operating current less than 5A, working voltage less than 300V.

Accessories

Hot Searches