- Product Details

- {{item.text}}

Quick Details

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KUSK

-

Voltage:

-

A.C.380V 50HZ

-

Power (kW):

-

185

-

Weight (KG):

-

49000 KG

-

Name:

-

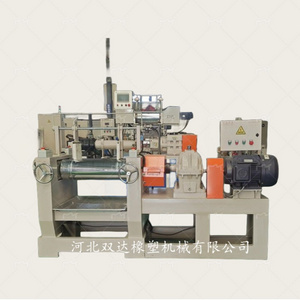

Rubber Open Roll Mill

-

Application:

-

Manufacturing Plant, Machinery Repair Shops

-

Model:

-

XK-660

-

Mixed capacity:

-

165kg

-

Function:

-

Rubber Processing

-

Keywords:

-

Roller Mixer

-

Lubrication:

-

Automatic Lubrication

-

Nip Adjustment:

-

Hydraulic

-

Motor:

-

185KW

-

Type:

-

Open Mixing Mill

Quick Details

-

Diameter of Roll(mm):

-

660 mm

-

Length of Roll(mm):

-

2130 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

water cooling

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

KUSK

-

Voltage:

-

A.C.380V 50HZ

-

Power (kW):

-

185

-

Weight (KG):

-

49000 KG

-

Name:

-

Rubber Open Roll Mill

-

Application:

-

Manufacturing Plant, Machinery Repair Shops

-

Model:

-

XK-660

-

Mixed capacity:

-

165kg

-

Function:

-

Rubber Processing

-

Keywords:

-

Roller Mixer

-

Lubrication:

-

Automatic Lubrication

-

Nip Adjustment:

-

Hydraulic

-

Motor:

-

185KW

-

Type:

-

Open Mixing Mill

Rubber Mixing mill with stock blender / open mixing mill

Brief description:

1.rollers,chilled cast iron

2.water or steam cooling system

3.hardened reducer ,bearing bush

4.welded or casting base

5.HS of rollers:75-80

1. Main features:

(1) materials of Rolls :chilled Cast iron alloy (LTG-H), after quenching and precision processing, hardness HS 78.

(2) in bearing : Dual-listed rolling bearings, which reduces energy consumption by 40%.

(3) roll gap adjustment: electric automatic or manual

(4) Voltage: 220v, 380v, 415v Frequency control of motor speed or as per customer's request

(5) reducer: Airtight leaching oil type, ZSYE reducer (There are a variety of choice: hardened tooth, gear wheel reducer. the price is different), Almost no noise, safety and durable

2.Materials of Rolls:

The roller are made of chilled cast iron alloy (LTGH), whose surface is 78HS, after quenching

and precision processing it is harder than other company,(they are usually 72HS ) .

The working surface is well grinded and machined.temperature uniformity in smooth surface, high hardness and long working life.

3. Motor:

We always use OMRON,SIMENS ect brand electric parts or you can choice the ordinary brand. All the motor is high quality and effiency, save energy, low noise, and small vibration.

4. Roll gap adjustment:

Roll nip adjustment is realized by hand or electricity which can obtain high accuracy and sensitivity.

5. Reducer:

The speed reducer is hardened tooth with class 6 precision, no noise and vibration, safety with higher transmission efficiency.(There are a variety of choice, the price is different),Gear Box(double out shaft transmission).

6. Frame:

The base frame is a whole framework and cast iron, which is convenient for installation and easy to maintain.

7. Stock bender:

It for direct rubber sheet and knife to cut as your need to assemble. Then improve the quality of mixing, and reduce the energy consumption.

8. Emergency brake device:

The machine is also equipped with an emergency brake device. When an emergent arises, just draw the safety pull rod or press the emergency button and the machine will stop immediately. It is safe and reliable.

The machine is equipped with an overload protection device to prevent the main components from being damaged.

9. Cooling system: (with rotating joint)

Universal rotary joints with inner spray pipes with hoses and headers. Piping is complete up to supply pipe terminal, which reduces energy consumption by 50% and high efficiency.

10. Auto-lubrication system for grease or oil and match bearing bush.

|

Xk-160 |

Xk-250 |

Xk-300 |

Xk-400 |

Xk-450 |

Xk-560 |

Xk-660 |

|

|

Working diameter of rolls(mm) |

160 |

250 |

300 |

400 |

450 |

560 |

660 |

|

Working length of rolls(mm) |

320 |

620 |

750 |

1000 |

1200 |

1530 |

2130 |

|

Front roll surface speed(m/min) |

8.99 |

15.3 |

15.1 |

18.65 |

24.32 |

27.72 |

28.6 |

|

Friction ratio |

1:1.35 |

1:1.1 |

1:1.27 |

1:1.27 |

1:1.27 |

1:1.2 |

1:1.24 |

|

Max.nip(mm) |

4 |

8 |

8 |

10 |

15 |

15 |

15 |

|

Capacity per.batch(kg) |

1-2 |

10-15 |

15-20 |

18-35 |

25-50 |

35-50 |

165 |

|

Motor power (kw) |

5.5 |

18.5 |

25 |

45 |

70 |

110 |

245 |

|

Overall dimension(mm |

1160*920 *1370 |

3120*1322 *1500 |

3580*1550 *1695 |

4350*1850 *1780 |

5670*2390 *1670 |

5845*2284 *1978 |

7465*3662 *2080 |

|

Weight(kg) |

1000 |

4000 |

5200 |

8000 |

12000 |

23000 |

49000 |

...

.......

FAQ:

Q1: Where is your factory located?

A1:

we

are in Qingdao city, Shandong Province, China

Q2: Are you an integrated supplier for rubber & plastic machine ?

A2: Yes, we can provide the complete solution line to customer according to customer’s requirement.

Q3: How about the quality control in your factory?

A3:

We have

the SOP (Standard Operation Procedure) and all the production step must follow up this SOP. Every machine needs at least automatic running over 72 hours and must be inspected carefully before shipment.

Q4: Will you offer the pre-sales service?

A4: Yes, we have an experienced pre-sales team to support customers not only including machine, technology also water

.electrical, machine layout in factory, etc.

Q5: What about the after-service? Will you send your engineer to my country to help commission and install the machine?

A5: Surely, we have many experience technical engineers for oversea service, they would help you install machine and train workers also.

Q6: What is the delivery time of the machine?

A6: Actually, the delivery time of the machines is depended on the machine options. Normally, the delivery time of standard machine could be within 30 days

Q7 : What is the warranty of the machine ?

A7: The whole machine’s warranty period is 12 months and key parts will be depended.

Q8 : Do you provide any spare parts with machine?

A8: Yes, we will provide one set standard spare parts to customer according to different machines