pump speed control (to reduce foam), and ease of operation.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1%

-

Voltage:

-

220

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JPACKS

-

Dimension(L*W*H):

-

2000mm*1200mm*1800mm

-

Weight:

-

400 KG

-

Product name:

-

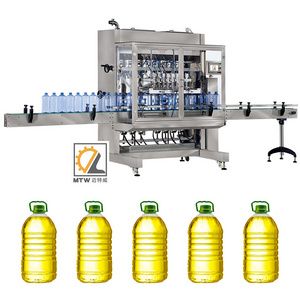

Oil drum filling machine

-

After-sales Service Provided:

-

Online Support

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Processing Types:

-

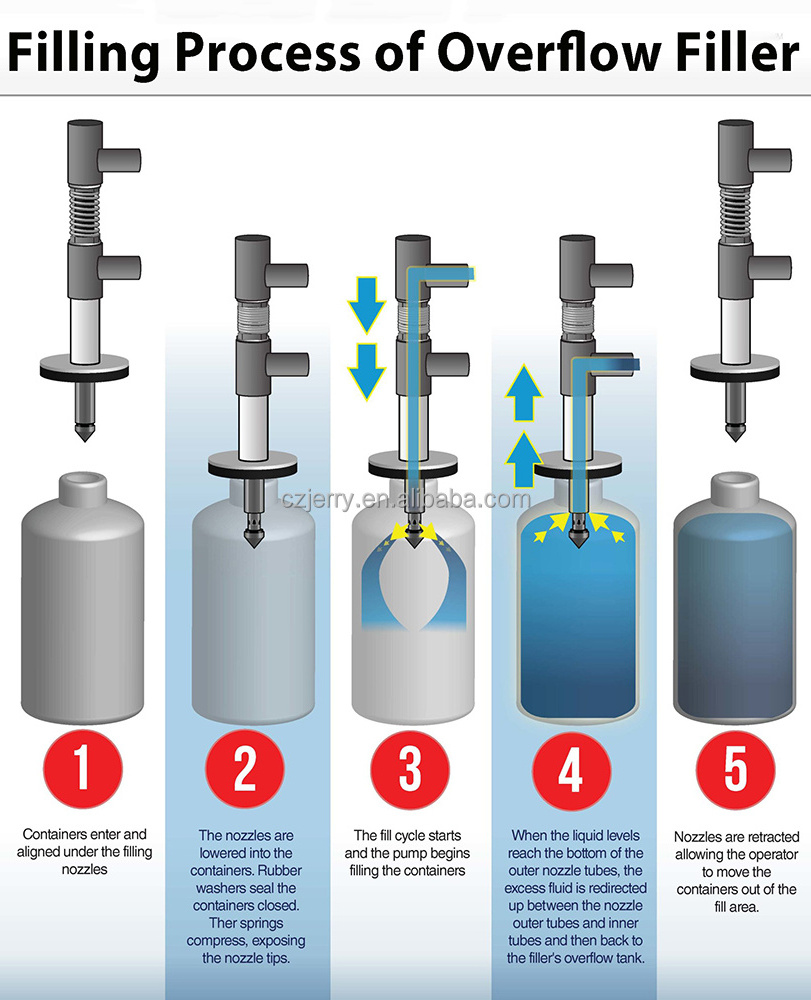

Overflow

-

Feature:

-

Consistent visual fill level

-

Filling volume:

-

50ml-25000ml

-

Control:

-

PLC+ Touch Screen

-

Filling nozzles:

-

4/6/8/12/16(customized)

-

Keywords:

-

Oil drum filling machine

-

Marketing Type:

-

New Product 2021

Quick Details

-

Machinery Capacity:

-

4000BPH, Other, 6000BPH, 16000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Other, Milk, Water, Oil, Juice, Spirits

-

Filling Accuracy:

-

1%

-

Voltage:

-

220

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JPACKS

-

Dimension(L*W*H):

-

2000mm*1200mm*1800mm

-

Weight:

-

400 KG

-

Product name:

-

Oil drum filling machine

-

After-sales Service Provided:

-

Online Support

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Processing Types:

-

Overflow

-

Feature:

-

Consistent visual fill level

-

Filling volume:

-

50ml-25000ml

-

Control:

-

PLC+ Touch Screen

-

Filling nozzles:

-

4/6/8/12/16(customized)

-

Keywords:

-

Oil drum filling machine

-

Marketing Type:

-

New Product 2021

Products Description

pump speed control (to reduce foam), and ease of operation.

Product Application

Product Features

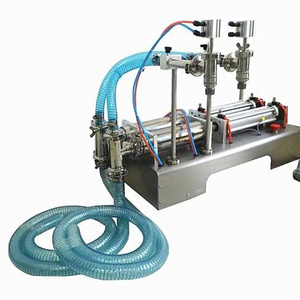

Construction Features

304 Stainless steel heavy duty stainless steel welded C frame. 20 Gallon stainless steel overflow tank. Stainless steel cover for

overflow tank. 20 hose 304 stainless steel feeding manifold. All contact parts are stainless steel, sanitary, Teflon, viton and

hoses per your requirements. Special seals or hoses by order. Calibrated guide for fast height changeovers.

Filling machine mounted on 4 heavy duty casters. Leveling of machine by 1 inch 304 stainless steel leveling screws.

overflow tank. 20 hose 304 stainless steel feeding manifold. All contact parts are stainless steel, sanitary, Teflon, viton and

hoses per your requirements. Special seals or hoses by order. Calibrated guide for fast height changeovers.

Filling machine mounted on 4 heavy duty casters. Leveling of machine by 1 inch 304 stainless steel leveling screws.

Control Panel Features

SIEMENS PLC for all machine logic functions, special modifications on programs available for special adaptations. Frequency control

drive for pump speed, acceleration and deceleration. Front panel bottle filling time adjustment through Timer. Front panel

conveyor speed control for machine sold with conveyor. Front panel mounted bottle counter. Front panel Start and Emergency STOP

for easy access. Front panel nozzle code for changing nozzle quantities. Fiber optic sensors by Omron standard for container

gating. Expandable to 20 nozzles to increase speed. No bottle no fill PLC controlled.

drive for pump speed, acceleration and deceleration. Front panel bottle filling time adjustment through Timer. Front panel

conveyor speed control for machine sold with conveyor. Front panel mounted bottle counter. Front panel Start and Emergency STOP

for easy access. Front panel nozzle code for changing nozzle quantities. Fiber optic sensors by Omron standard for container

gating. Expandable to 20 nozzles to increase speed. No bottle no fill PLC controlled.

Main Components Features

96 Gallon per minute, 1 Hp, 3phase, 316 stainless steel centrifugal pump. Hardened Stainless steel calibrated shafts with linear

bearings for nozzle rack movement smoothness and durability. 10 inch stroke air cylinder with magnetic sensors for nozzle up and down movement. 316L Stainless steel sanitary check valve mounted on pump. Hand wheel and shaft mounted stoppers for height and stroke adjustment.

bearings for nozzle rack movement smoothness and durability. 10 inch stroke air cylinder with magnetic sensors for nozzle up and down movement. 316L Stainless steel sanitary check valve mounted on pump. Hand wheel and shaft mounted stoppers for height and stroke adjustment.

Standard Features

Nozzle spacing fully adjustable through top screw. Container height adjustment from 1 to 16 inches high. Nozzle stroke adjustments

from 0 to 10 inches. Entry and exit bottle gating cylinders adjustable, sideways, up and down and inside and outside. Will work

with plastic or glass containers. No change parts needed for various types of containers. Air filter-regulator and safety lockout

valve included. Spacing and additional bottle control obtained by flow controls mounted on air gating cylinders.

from 0 to 10 inches. Entry and exit bottle gating cylinders adjustable, sideways, up and down and inside and outside. Will work

with plastic or glass containers. No change parts needed for various types of containers. Air filter-regulator and safety lockout

valve included. Spacing and additional bottle control obtained by flow controls mounted on air gating cylinders.

Technical Parameters

|

Filling range

|

50ml-25000ml

|

|

|

|

|||

|

Filling heads

|

4/6/8/12/16 ((can be customized according to customer needs))

|

|

|

|

|||

|

Supply Voltage

|

220V; 50 / 60HZ

|

|

|

|

|||

|

Power Consumption

|

1.5kw

|

|

|

|

|||

|

Air Pressure

|

0.4-0.6Mpa

|

|

|

|

|||

|

Machine Dimension

|

3000mm*2000mm*1250mm

|

|

|

|

|||

Why Choose JERRY PACK

Changzhou Jerry Packaging Technology Co., Ltd. is specializing in packaging machinery R & D, manufacturing and sales.Our liquid bottle packaging technology is most advanced in China.All products are in accordance with the national "GMP" standard. The advanced design concepts and professional technology has been a prominent feature of Jerry Packaging Technology.We have perfect manufacturing system. We manage service after sale strictly and considerately.Jerry Packaging Technology has won a good reputation in the area.

OUR FACTORY

OUR TEAM

INTERNATIONAL EXHIBITION

OUR MACHINE IN CUSTOMER

OUR COMPONENT

SUPPLIERS

QC & INSPECTION

THROUGH WHOLE PRODUCTION PROCESS

ALL RAW MATERIALS

ALL PARTS

ALL COMPONENTS

Our Service

OUR SERVICES

For All Your Packaging Needs

Packaging line design and consultation

Factory acceptance testing

Installation, startup, and training

Free technical online support

Field service and preventative maintenance

FAQ

Q1: Are you factory or trading company?

A: We are factory or manufacturer.

Q2: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we put a high value on our reputation. Best quality is our principle all the time. You can be assured on our

oil drum filling machine

completely.

Q3: What should I do if we are not able to operate the

oil drum filling machine

when we receive it?

A: Operation manual and video demonstration sent along with the

oil drum filling machine

to give instructions. Besides, we have professional after-sale group to customer 's site to solve any problems.

Q4: How could I get the spares on

oil drum filling machine

?

A:We will send extra sets of easy broken spares and accessories like O ring etc. Non-artificial damaged spares will be sent freely and shipping free during 1 year's warranty.

Q5: Is there any insurance which I pay for to guarantee I will get the right

oil drum filling machine

?

A: We are an onsite check supplier from Alibaba. Trade Assurance provides quality protection, ontime shipment protection and 100% safe payment protection. Our factory already highest stars of the grade.

Q6.What's the payment terms and trade terms for new customers?

A: Payment terms:30% T/T DEPOSIT PAYMENT IN ADVANCE,BALANCE 70% AGAINST COPY OF B/L.WESTERN UNION,LC ARE ACCEPTABLE.

Q7:What's the Minimum Order Quantity and warranty?

A:MOQ:1 set Warranty:12 months,some customized products will be 24 months.

Q8:Do I need to pay for the extra cost like tax or duty ?

A:It is the buyers' responsibility to pay the custom duty.The shipping fee will not include the tax,please pay attention to this.

Recommend Products

Hot Searches