- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

580

-

Voltage:

-

110V/220V/380V/415V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Autompack

-

Dimension(L*W*H):

-

3770*1000*1380mm

-

Vendor Model:

-

ATM-350XQ-105D/ATM-350XQ-135D

-

Single Knife Making Bag Size:

-

L(85-350)*W(50-160)*H(3-65)mm

-

Double Knife Making Bag Size:

-

L(60-145)*W(30-90)*H(3-55)mm

-

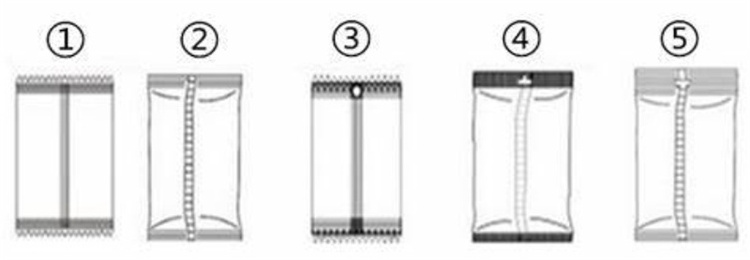

Bag type:

-

Pillow bag

-

Extruder type:

-

Single screw diameter

-

Film material:

-

32*15(25g),44*18MM(50g),58*26(100g) ,75*30MM(250g)

-

Packing speed:

-

30-200bags/min

-

Bag size:

-

(80-160)*(30-150)*(3-45)mm

-

Packaging weight:

-

≤350mm(20-250g)

-

Thickness of packaging film:

-

25-70um

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Laminating, Capping, COATING, Sealing, BOXING, Embossing, Gluing, SLITTING

-

Packaging Type:

-

Film, Foil

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

580

-

Voltage:

-

110V/220V/380V/415V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Autompack

-

Dimension(L*W*H):

-

3770*1000*1380mm

-

Vendor Model:

-

ATM-350XQ-105D/ATM-350XQ-135D

-

Single Knife Making Bag Size:

-

L(85-350)*W(50-160)*H(3-65)mm

-

Double Knife Making Bag Size:

-

L(60-145)*W(30-90)*H(3-55)mm

-

Bag type:

-

Pillow bag

-

Extruder type:

-

Single screw diameter

-

Film material:

-

32*15(25g),44*18MM(50g),58*26(100g) ,75*30MM(250g)

-

Packing speed:

-

30-200bags/min

-

Bag size:

-

(80-160)*(30-150)*(3-45)mm

-

Packaging weight:

-

≤350mm(20-250g)

-

Thickness of packaging film:

-

25-70um

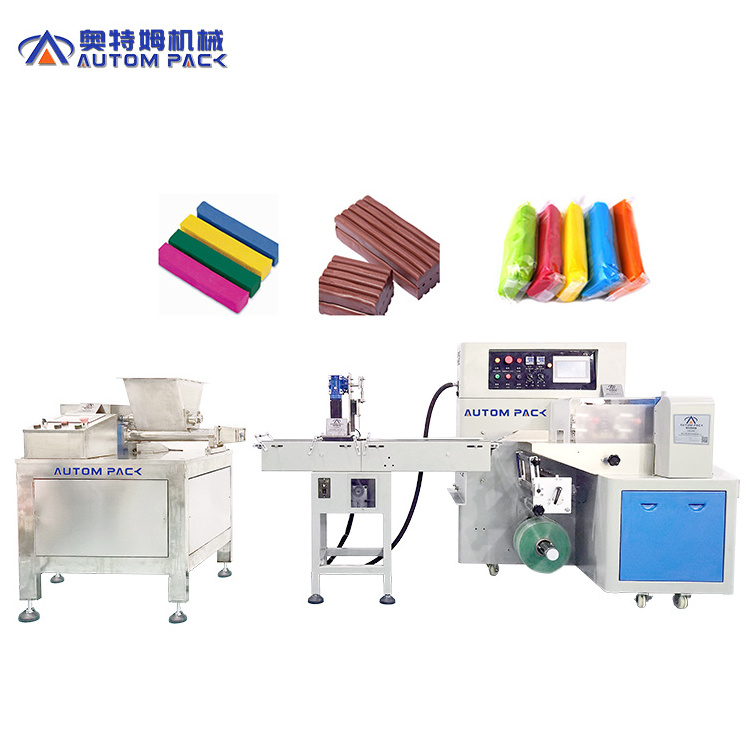

Autompack Factory Precut Aluminum Foils Bag Filling Hookah Tobacco Packing Machine for Smoking Shisha Hookah Charcoal 40mic Thick 50pcs/pack

Product Description

ATM-350XQ-105D/135D Horizontal Packing Machine is a kind of advanced equipment applicable for such different materials as composite film, paper film and aluminum film to pack various solid and regular-shaped objects.

Can be applied to:

Food (snack bar, bread, cookies, ice lolly cake, chocolate bar, ice cream bar, biscuit), Plastic(cutlery, clay, shisha hookah, mud), Hardware, Soap, sponge, tissue, card etc.

Packaging various kinds of regular objects.

Packing material and size detail:

Packaging film: PPOP/CPP, POPP/VMCPP, CPP/PE and so on.

The motor of the packaging machine can be a variable frequency motor or a servo motor. The servo motor can control the length of the package through the sensor, and the equipment automatically adjusts. Frequency conversion motors need to be adjusted on system. The width of the packaging can be adjusted by changing the size of the packaging film and adjusting the size of the former

Main features:

1. Panasonic double transducer control, flexible bag length cutting. Save time and film.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable, convenient for parameters adjusting.

4. Self diagnosis failure function, machine error can be clearly displayed.

5. Separate PID temperature controller, suitable for various packing materials

6. High sensitivity optical photocell for eye mark tracking, digital input for cutting position.

7. Position stop function, no adhesive and no waste of membrane and protect cutting jaws.

8. Simple driving system, stable performance and convenient maintenance.

9. According to product, the input conveyor can use pusher, belt or film for transportation.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable, convenient for parameters adjusting.

4. Self diagnosis failure function, machine error can be clearly displayed.

5. Separate PID temperature controller, suitable for various packing materials

6. High sensitivity optical photocell for eye mark tracking, digital input for cutting position.

7. Position stop function, no adhesive and no waste of membrane and protect cutting jaws.

8. Simple driving system, stable performance and convenient maintenance.

9. According to product, the input conveyor can use pusher, belt or film for transportation.

Technical Parameter

| Table of technical parameters of full automatic extrusion and quantitative packing machine for plasticene (down film) | |||||

| Vendor Model |

ATM-350XQ-105D color mud |

ATM-350XQ-135D Ultralight clay |

ATM-350XQ-130S Oilsludge, mastic |

||

| Width of film | ≤ 350mm | ≤ 350mm | ≤ 350mm | ||

| Extruder Type | ATM-105D Diameter of single screw barrel130MM | ATM-135D Diameter of single screw barrel160MM | ATM-100D single screw 2-15g | ATM-100S double screw 2-50g |

ATM-130S double screw 2-500g |

| Mold range | Φ10-Φ30 | Φ10-Φ55 |

width20-60MM height3-25MM |

width30-80MM height3-50MM |

width45-130MM height3-50MM |

| Thickness of film | 25-70um | ||||

| Dimension of film roll | external diameterOUTER DIAMETER ≤Φ300mm ,internal diameterINNER DIAMETER ≤Φ75mm | ||||

| Quantitative cut-off | Double knife35MM) | Single knife (25MM) | Single knife (25MM) | ||

| Single Knife |

Bag size: (85-350)*(50-160)*(3-65) mm (L*W*H) Speed: 200 bags/min |

Bag size: (85-350)*(50-160)*(3-65) mm (L*W*H)

Speed:200 bags/min |

Bag size: (85-350)*(50-160)*(3-65) mm (L*W*H)

Speed: 200 bags/min |

||

| Double Knife |

Bag size: (60-145)*(30-90)*(3-55) mm (L*W*H)

Speed: 200 bags/min |

Bag size: (60-145)*(30-90)*(3-55) mm (L*W*H)

Speed: 200 bags/min |

Bag size: (60-145)*(30-90)*(3-55) mm (L*W*H)

Speed: 200 bags/min |

||

| Power | 220V/380V,50HZ/60HZ, 7.5KW | 220V/380V,50HZ/60HZ, 7.5KW | 220V/380V,50HZ/60HZ, 10.5KW | ||

| Outer dimensions | 3770 * 1000 * 1380mm (L*W*H) | 3300 * 900 * 1380mm (L*W*H) | 4000 * 1100 * 1380mm (L*W*H) | ||

| Gross weight | 800kg | 750kg | 900kg | ||

| Optional device | Printer | ||||

Hot Searches