- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friendpack

-

Dimension(L*W*H):

-

75*50*50cm

-

Weight:

-

40 KG

-

Product name:

-

powder dispensing machine

-

Function:

-

Weight Filling Machine

-

Bottle type:

-

Stand-up Pouch, Bags, Pouch

-

Capacity:

-

15-30 bags Per Minute

-

Filling range:

-

20/50/100/200/1000g

-

Feature:

-

High Efficiency

-

Keywords:

-

Powder Packing Machine

-

Material:

-

StainlessSteel

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Machinery Capacity:

-

12000BPH

-

Packaging Material:

-

Plastic, Paper, Glass

-

Filling Material:

-

Beer, Milk, Water, Juice

-

Filling Accuracy:

-

1%

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friendpack

-

Dimension(L*W*H):

-

75*50*50cm

-

Weight:

-

40 KG

-

Product name:

-

powder dispensing machine

-

Function:

-

Weight Filling Machine

-

Bottle type:

-

Stand-up Pouch, Bags, Pouch

-

Capacity:

-

15-30 bags Per Minute

-

Filling range:

-

20/50/100/200/1000g

-

Feature:

-

High Efficiency

-

Keywords:

-

Powder Packing Machine

-

Material:

-

StainlessSteel

-

Marketing Type:

-

Ordinary Product

This product is suitable for granular,powdery products, rice, millet, whole grains, vegetable seeds, frtilier, tea, alfalfa, dog

food, fish, dried fruit,nuts, herbs, salt, spices, chestnut, dried longan, electronic originals, original hardware, small plastic

parts, etc.

food, fish, dried fruit,nuts, herbs, salt, spices, chestnut, dried longan, electronic originals, original hardware, small plastic

parts, etc.

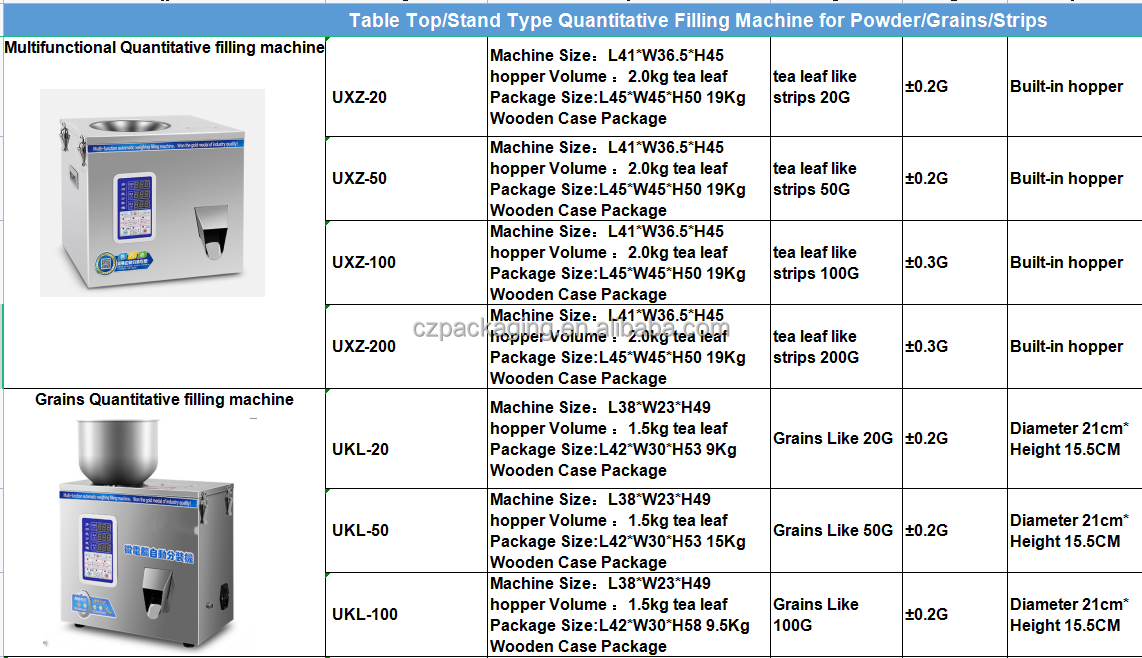

Products Description

|

Device name

|

F Type Granule powder sorting machine

|

|

VOLTAGE

|

220V/50Hz

|

|

Working principle

|

Automatic

|

|

Packing range

|

10g-999g/10g-1500g/20g-3000g/50g-5000g/100g-999g/0.5KG-15KG

|

|

Product error

|

0±0.2g

|

|

Scope of application

|

Tea, pellets, grains, powder, etc.

|

Features

*Full of intelligent design, simple operation.

*Stainless steel housing, the appearance of fine high-end.

*Automatic micro-computer control system.

*Scientific weighing and filling process.

*Infrared sensor device, items drop automatically once your hand is sensed by the sensor.

*Three level vibration cutting, the machine is running smoothly.

*Adjustable packing speed and accuracy.

*Operational process can be checked through the window on the surface.

*Full of intelligent design, simple operation.

*Stainless steel housing, the appearance of fine high-end.

*Automatic micro-computer control system.

*Scientific weighing and filling process.

*Infrared sensor device, items drop automatically once your hand is sensed by the sensor.

*Three level vibration cutting, the machine is running smoothly.

*Adjustable packing speed and accuracy.

*Operational process can be checked through the window on the surface.

Manufacturing Technique

01.Smart computer version design

The use of microcomputer intelligent control makes the sub-assembly more precise and accelerated, and the automation of the sub-assembly process makes it easier for you to operate.

02.HD viewing window

The visual viewing port is more convenient than the traditional stainless steel cover, and the feeding situation inside can be easily observed.

03.Infrared sensor

There is an infrared sensor at the bottom of the blanking outlet, and the hand reaches out to sense the blanking without manual switching.

04.Insulated computer interface and switch

The product power cord is made of engineering plastics, highly insulated, no leakage, so that the machine is more stable and safe to use

05.High quality stainless steel pull buckle

The stainless steel pull buckle is used without the cover, which can be directly opened and taken out; the upper cover cleans theinternal walkway; the disassembly is simple, convenient and flexible.

06.Data port

A data port is installed on the right side of the machine, which can be transmitted with our packaging machine data line later to achieve automatic packaging.

Product Application

Catalog

Production Process

About Us

Upack Imp. And Exp.,Ltd

is a Professional One-Stop Packing Solution Provider of Fill-Label-Cap-Shrink-Carton-Seal-Strap-Wrap-Convey-Stack process, Which has been focusing on the planning, R&D and manufacturing of automatic packaging production line. such as automatic carton packing line,shrinking wrapping line, Fully automatic pallet strapping line,Conveyor system and so on. Our company are providing one-stop purchase expereinces for customers. Our productions have beening exported to Europe, North America, the Middle East, Southeast Asia and more than 30 other Countries.

FAQ

1: Are you a factory or trading company?

A: As the pictures I show you in above, located in Changzhou city,we are the factory and our mainly products is: Auto capping machine, Auto labeling machine, and some semi-auto machine,also we can make production line based on your requirements.

2:What's the payment terms?

A: TT transfer,L/C and other payment methods if it is convenient for you.

3:What's the warranty of your equipment?

A:1 year warranty on the machine core after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support service in after-sales.We test every machine manually to make sure they are in good condition before they are sent to your place.

4:What is the service?

7 days 24 hours on line service,engineer overseas service is also available if necessary.

5:What's your advantage? Why we choose you?

A1: We have the most professional techniques and team, we are able to customiz machines according to the customer requirements,which is hardly acquired from other suppliers.

A2:We are a professional manufacturer and warmly welcome clients from worldwide to visit our factory and cooperate with us.

In order to meet the growing international demand, our company is looking for motivated agents to promote products all over the world. If you are interested in a partnership, please contact us and we will contact you as soon as possible.

Please don't hesitate to send us an inquiry for any other questions ,We will come back soon with proper solution.

Hot Searches