- Product Details

- {{item.text}}

Quick Details

-

Range of Spindle Speed(r.p.m):

-

20 - 8000

-

Spindle Taper:

-

BT40

-

Repeatability (X/Y/Z) (mm):

-

0.01

-

Place of Origin:

-

China

-

Brand Name:

-

NEWKer

-

Table Travel (mm):

-

1500x420

-

Voltage:

-

3Phase 220V 380V

-

Dimension(L*W*H):

-

2700*1800*2200

-

Weight (KG):

-

3200

-

Max. Table Load(kg):

-

5 kg

-

Machine Type:

-

Machining Center

-

Product name:

-

NEWKer

-

Model:

-

CNC-950QM

-

Precision:

-

±0.015

-

CNC Controller:

-

NEWKer

-

Axis:

-

2-6 Axis

Quick Details

-

Table Travel (X) (mm):

-

800 mm

-

Table Travel (Y) (mm):

-

500

-

Table Travel (Z) (mm):

-

500

-

Range of Spindle Speed(r.p.m):

-

20 - 8000

-

Spindle Taper:

-

BT40

-

Repeatability (X/Y/Z) (mm):

-

0.01

-

Place of Origin:

-

China

-

Brand Name:

-

NEWKer

-

Table Travel (mm):

-

1500x420

-

Voltage:

-

3Phase 220V 380V

-

Dimension(L*W*H):

-

2700*1800*2200

-

Weight (KG):

-

3200

-

Max. Table Load(kg):

-

5 kg

-

Machine Type:

-

Machining Center

-

Product name:

-

NEWKer

-

Model:

-

CNC-950QM

-

Precision:

-

±0.015

-

CNC Controller:

-

NEWKer

-

Axis:

-

2-6 Axis

Poster

Product

If you want more models of machine tools please contact us and we will send the catalog to you

Product detail:

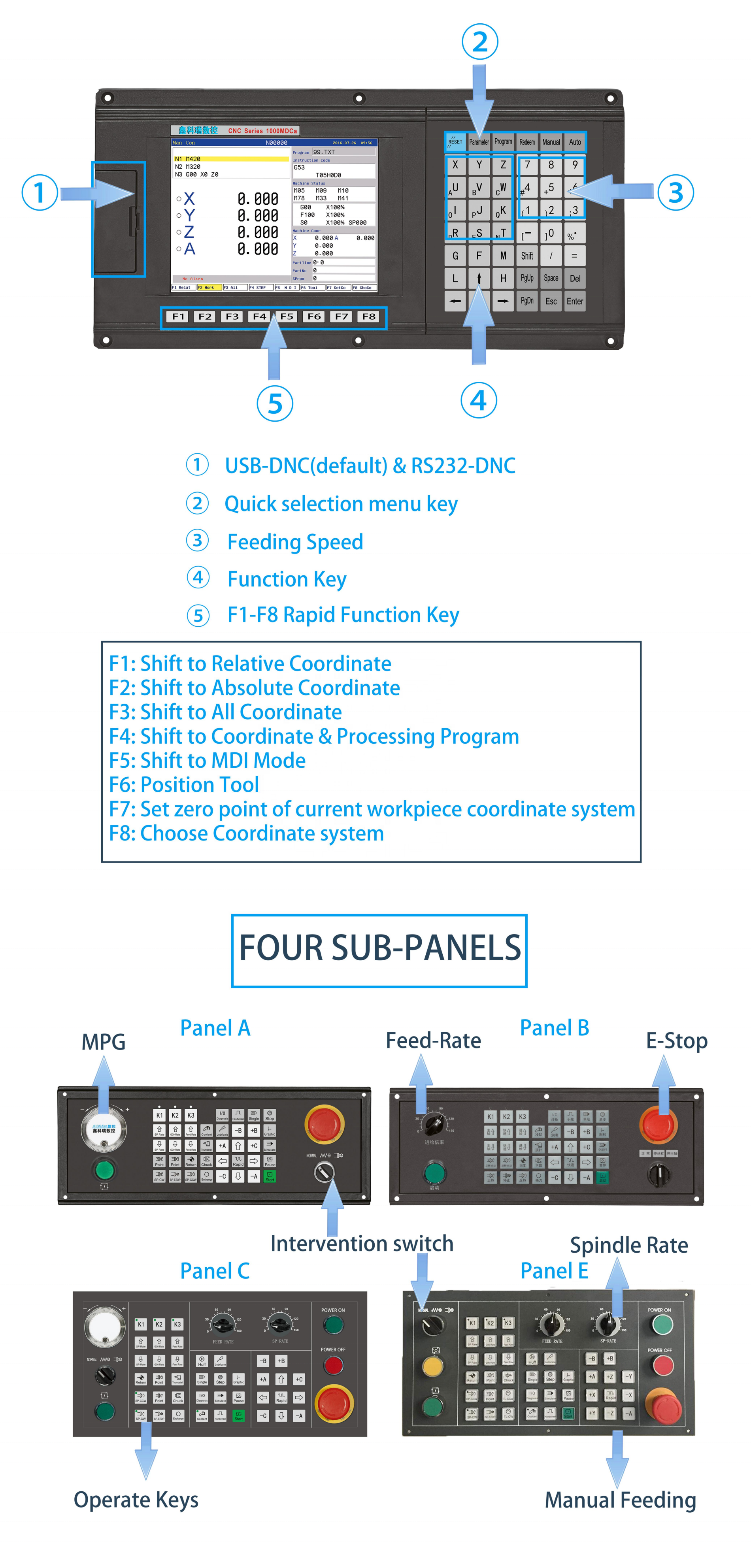

Subpanel:

It can be selected according to your needs

If you want more models of machine please contact us and we will send the catalog to you.

|

Item

|

Unit

|

Machine model

|

|

|

|

CNC-950QM

|

|

X axis travel

|

mm

|

800

|

|

Y axis travel

|

mm

|

500

|

|

Z axis travel

|

mm

|

500

|

|

Distance from spindle nose to the worktable

|

mm

|

120-620

|

|

Distance from spindle center to column guide rail surface

|

mm

|

580

|

|

X rapid feed G0

|

mm/min

|

30000

|

|

Y rapid feed G0

|

mm/min

|

30000

|

|

Z rapid feed G0

|

mm/min

|

24000

|

|

Cutting speed

|

mm/min

|

8000

|

|

Work table size

|

mm

|

1500*420

|

|

The maximum load capacity of working table

|

KG

|

350

|

|

Table "T" type groove number

|

pcs

|

3

|

|

Table "T" type groove width

|

mm

|

18

|

|

Table "T" type groove Spacing

|

mm

|

100

|

|

Unidirectional positioning accuracy

|

mm

|

0.015

|

|

Repeat positioning accuracy

|

mm

|

0.01

|

|

Spindle speed range

|

rpm/min

|

20-8000

|

|

Feed axis motor power

|

KW

|

1.6/2/2.5

|

|

Feed motor connection form

|

|

Direct installation

|

|

Taper of spindle hole

|

|

BT40

|

|

Tool standard

|

|

MSA403 BT40

|

|

Rivet standard

|

|

MSA403 P40T-1

|

|

The spindle of output power

|

KW

|

5.5

|

|

Cooling box form

|

|

independent

|

|

Tool magazine type

|

|

Umbrella

|

|

Tool number

|

pcs

|

12

|

|

Maximum tool diameter

|

mm

|

75

|

|

Maximum tool weight

|

kg

|

5

|

|

Maximum tool length

|

mm

|

300

|

|

Dimension of machine

|

mm

|

2700*1800*2200

|

|

Weight of machine

|

KG

|

3200

|

|

Working environment

|

|

0~45℃

20%~80% |

|

Controller Parameter details

|

|

|

|

|||

|

System Function

|

|

G code shows

|

|

|||

|

Number of control axis

|

3~8(X,Y,Z,A,B,C,Xs,Ys)

|

Locate rapidly:

|

G00

|

|||

|

The smallest programming:

|

0.001mm

|

Straight line interpolation

|

G01

|

|||

|

The most programming:

|

±99999.999mm

|

Arc interpolation:

|

G02/03

|

|||

|

The highest speed:

|

60m/min

|

Thread cut:

|

G32

|

|||

|

Feed speed:

|

0.001~30m/min

|

Cycle of cutting cyliner or cone:

|

G90

|

|||

|

Continuous manual:

|

one axis or multiple axis at the same time

|

Cycle of cutting end face:

|

G94

|

|||

|

Line interpolation:

|

Straight line, arc, screw thread interpolation

|

cycle of cutting thread

|

G92

|

|||

|

Cutter compensation:

|

Length of the compansation、radius nose of tool compensation

|

Fixed cycle of tapping

|

G93

|

|||

|

Cutter compensation input:

|

Try to cut measuring input mode

|

Cycle of rough cut in excircle

|

G71

|

|||

|

Spindle function:

|

gear、Double analog control、Rigid tapping

|

Cycle of rough cut at end face:

|

G72

|

|||

|

Handwheel function:

|

panel、handheld

|

Cycle of closed cut

|

G73

|

|||

|

handwheel processing:

|

The handwheel processing function

|

Cycle of drill deep hole at end face

|

G74

|

|||

|

Screen protection:

|

The screen protection function

|

Cycle of cutting groove with external diameter

|

G75

|

|||

|

Tool rest function:

|

Row tool rest、Electric too post 99 knife

|

Cycle of cutting compound thread

|

G76

|

|||

|

Communication function:

|

RS232、USB interface

|

Cycle of program

|

G22,G800

|

|||

|

Compensation function:

|

Tool compansation、Space compensation、Screw pitch compensation、Radius compensation

|

Local coordinate system:

|

G52

|

|||

|

Edit program:

|

Metric/Imperial、Straight thread、taper thread and so on

|

Detect the instruction of skip

|

G31,G311

|

|||

|

Limit position function

|

soft limit, hard limit

|

Pole coordinate

|

G15,G16

|

|||

|

thread function

|

metric and inch format, straight thread, taper thread and so on

|

Metrical/Imperial programme:

|

G20,G21

|

|||

|

Preread function:

|

Preread 10,000 short straight lines

|

Set coordinate, offset

|

G184,G185

|

|||

|

Password protection:

|

Multilevel password protection

|

Workpiece coordinate system:

|

G54~G59

|

|||

|

Input/output:

|

I/O 56*24

|

Tool radius C

|

G40,G41,G42

|

|||

|

PLC programme:

|

All open PLC design

|

Accurate locating/continuous path process:

|

G60/G64

|

|||

|

Acceleration and deceleration control:

|

Straight line、Index

|

Constant linear cutting:

|

G96/G97

|

|||

|

Number of encoder:

|

any setting

|

Feeding mode:

|

G98,G99

|

|||

|

User macro program:

|

Have

|

Backing to start point of program:

|

G26

|

|||

|

Electrical gear function:

|

Have

|

Backing to the fixed point:

|

G25,G61,G60

|

|||

|

Subpanel

|

A type with handwheel; B type with band switch; C type with both A and B, E type

|

Backing to the datum point:

|

G28

|

|||

|

Application:

|

VMC, grinding, special machine

|

Suspend:

|

G04

|

|||

|

|

|

Macro Program:

|

G65,G66,G67

|

|||

|

|

|

Auxiliary function:

|

S、M、T

|

|||

Function advantages

Product features

Never Crush the machine, the system with memorial function (Abosolute feature)

Needn't install hard limit with this 3 axis control wood drilling and milling machine and back to the zero point (Abosolute

feature)

Adapt bus modbus technology, ARM + DSP + FPGA technology

USB and RS232 port, DNC function of USB (NEW)

Network remote technology and could diagnose the system online (NEW)

User's storage is 128M and could be infinite number of program (NEW)

Abosolute type of motor (17bits multi circle) controlling technology (NEW)

The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

All closed-loop with grating ruler control and the accuracy is <2um (NEW)

Preread the short line program to satisfy with high speed engraving and cutting (NEW)

Intelligent Man-Machine dialog interface (NEW)

Needn't install hard limit with this 3 axis control wood drilling and milling machine and back to the zero point (Abosolute

feature)

Adapt bus modbus technology, ARM + DSP + FPGA technology

USB and RS232 port, DNC function of USB (NEW)

Network remote technology and could diagnose the system online (NEW)

User's storage is 128M and could be infinite number of program (NEW)

Abosolute type of motor (17bits multi circle) controlling technology (NEW)

The most moving rapid speed is 300m/min, processing speed reaches 0.01 ~ 30m/min (NEW)

The cycle of interpolation is 2ms, controlling accuracy is 0.1um (NEW)

All closed-loop with grating ruler control and the accuracy is <2um (NEW)

Preread the short line program to satisfy with high speed engraving and cutting (NEW)

Intelligent Man-Machine dialog interface (NEW)

Product applications

NEWKer is the manufacturer

We are a factory, not a trader, so we can provide you with low price but high quality products

This is our showroom:

About us

Certifications

Customer Photos

Why Choose Us

Main products

Rave

FAQ

PACKING & SHIPPING

Hot Searches