- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ASFL

-

Year:

-

2022

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

1908*1280*1920

-

Hollow part volume:

-

0.2L-2L

-

Clamping Force (kN):

-

1000KN

-

Power (kW):

-

12

-

Weight (KG):

-

1000 KG

-

After-sales Service Provided:

-

Bottle Blowing Machine

-

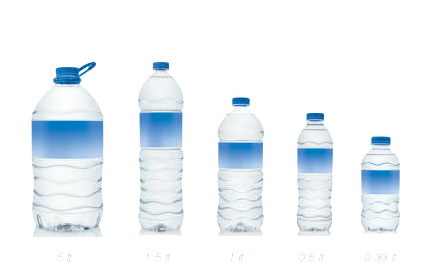

Suitable bottle:

-

Drink Bottle

-

Product name:

-

PET Blowing Machine

-

Capacity:

-

1500-8000PCS/H

-

After Warranty Service:

-

1year

-

Machine type:

-

Stretch Bottle Blowing

-

Material:

-

Stainless Steel 304/316

-

Color:

-

Customer Choice

-

Certification:

-

CE ISO

-

Blow Moulding Type:

-

Stretch Blow Moulding

Quick Details

-

Neck Diameter(mm):

-

2 mm

-

Max.Bottle Diameter(mm):

-

28 mm

-

Max.Bottle Height(mm):

-

360 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ASFL

-

Year:

-

2022

-

Voltage:

-

380V 50HZ 3P

-

Dimension(L*W*H):

-

1908*1280*1920

-

Hollow part volume:

-

0.2L-2L

-

Clamping Force (kN):

-

1000KN

-

Power (kW):

-

12

-

Weight (KG):

-

1000 KG

-

After-sales Service Provided:

-

Bottle Blowing Machine

-

Suitable bottle:

-

Drink Bottle

-

Product name:

-

PET Blowing Machine

-

Capacity:

-

1500-8000PCS/H

-

After Warranty Service:

-

1year

-

Machine type:

-

Stretch Bottle Blowing

-

Material:

-

Stainless Steel 304/316

-

Color:

-

Customer Choice

-

Certification:

-

CE ISO

-

Blow Moulding Type:

-

Stretch Blow Moulding

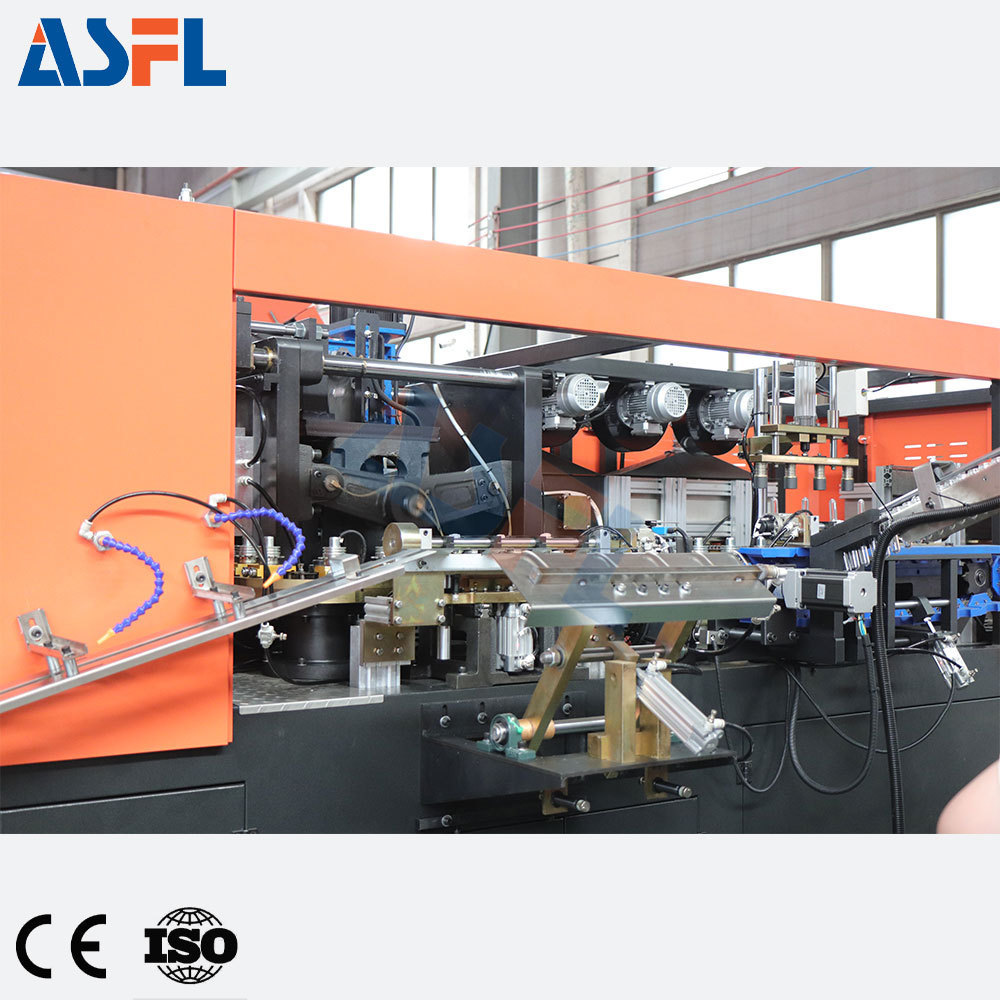

The two–step high speed automatic linear blow molding machines which are applicable in a wide range of PET packaging practice,such as for beverages, edible oil, food, pharmaceutical products and cosmetics,etc. With more than 10 years experience indeveloping and producing blow molding machine as well as the advanced technology absorbed domestic and abroad, we have developed with our constant innovation dozens of high speed and high precision equipments which have won the top reputation in the filed.

Final Products

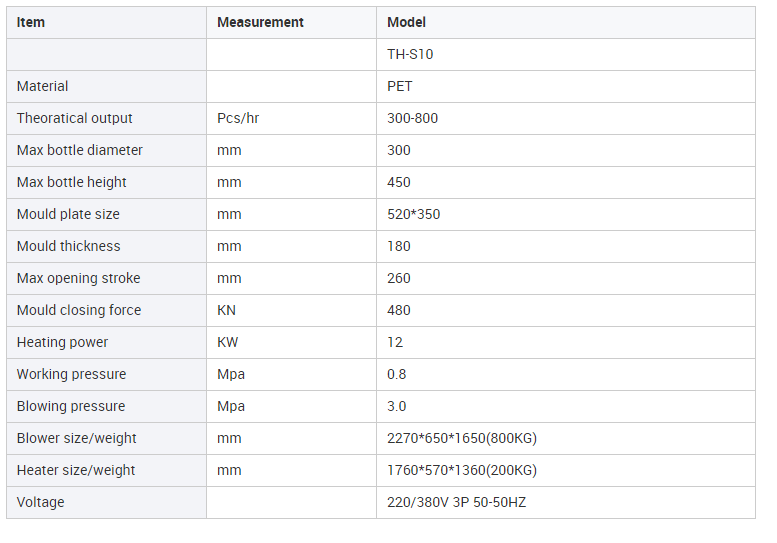

Product Paramenters

Product Description

Main Features

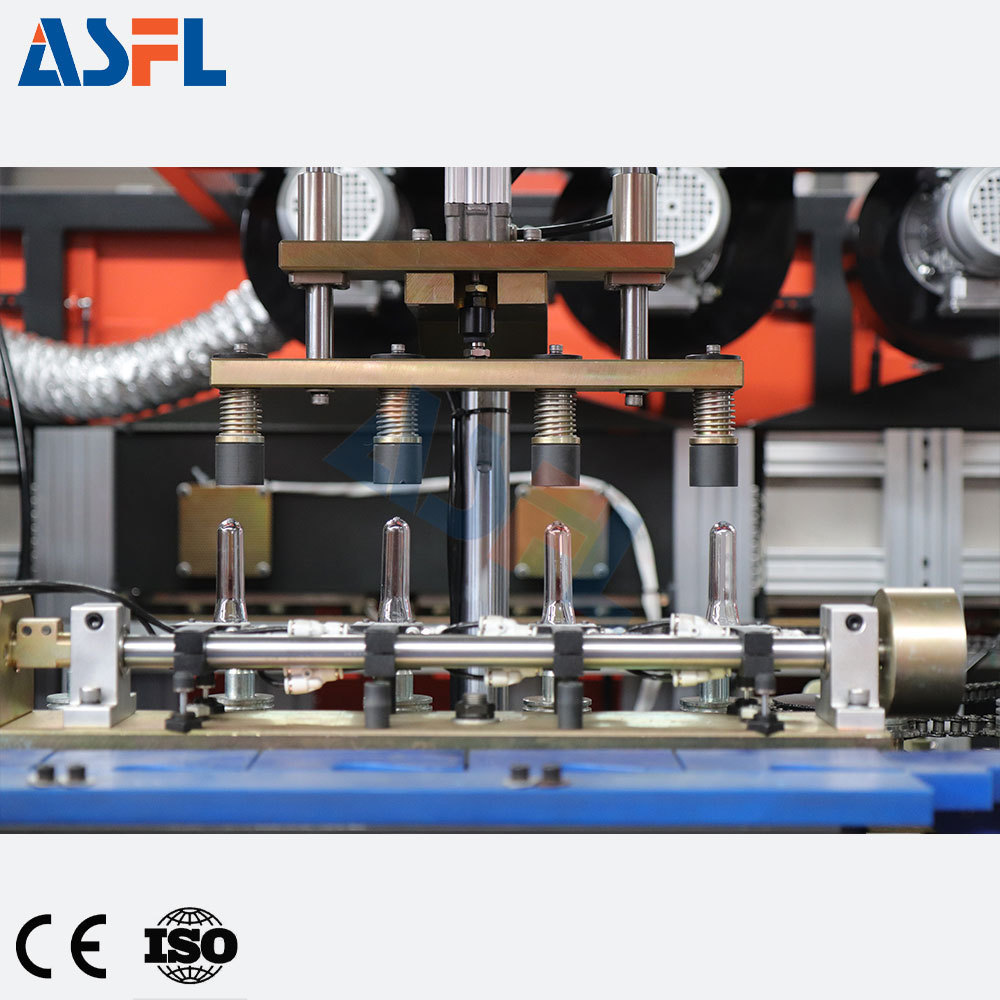

repeatable and consistently high bottle quality

2 - Production flexibility: Up to 200 different equipment size configurations from one platform

3 - Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 - Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 - Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

Product Details

- Safe,reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

- Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

- Ideal cooling system make the finished bottles without any flaws.

- Easy for you to install,test and start up.

- Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

- Ideal cooling system make the finished bottles without any flaws.

- Easy for you to install,test and start up.

Recommend Products

Why Choose Us

Ace-Filling Machine.

Ace-filling (Suzhou) Packaging Machinery Co., Ltd. is a professional manufacturer of liquid beverage packaging solutions. We supply bottle blowing machine, water treatment, water filling production line, carbonated drink making filling production line,beer wine alcohol filling production line, juice making filling production line, beverage canning machine, edible oil ketchup filling machine, 5 gallon filling production line, labeling machine and shrink packing machine. With our machines, bottles can be plastic bottle, glass bottle barrel and cans. In other words, machines can be customized according to client's requirements. We have exported to South East Asia, Middle East, Africa and South America and South East,more than 40 countries. We are always focusing on the researches and developments, since they are our key of enterprise innovation. They make us better doing inproduction,technical services and marketing sales.

Production Process.

In the production process, we strictly control the quality of the product.

It consists of ten processes, including welding,drilling,bending,machining,assembling,bebugging&test and acceptance.

After repeated testing, the practice finally put into use.

Our

Customers.

We have exported to South East Asia, Middle East, Africa and South America and South East,more than 40 countries. We are always focusing on the researches and developments, since they are our key of enterprise innovation.

FAQ

Q:Are you a manufacturer or trading company?

A:We are a manufacturer in beverage machine field more than 10 years, located at Leyu town, Zhangjiagang, 1.5 hours from Shanghai,1 hour from Wuxi by car. We will pick you up to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE

Q:What about the delivery time?

A:Usually 45 Working days

Q:The after-sale service

A:24 months warranty.

Solve basic questions by phone, email, whatsapp, Wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machine or by email.

Q:If our bottle size changes, can we just do some adjustment on machine according to our new bottle?

A:Yes.

* Please do not hesitate to contact me if you want more details!

Hot Searches