Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2024

-

Core Components:

-

IGBT, Control board

-

name:

-

induction heating generator

-

usage:

-

hardening, forging, brazing,annealing ,melting

-

processing work piece:

-

gear, shaft, steel rod, billets ,copper,aluminum

-

Color:

-

blue or black white

-

accessories:

-

induction coils

-

protect function:

-

OC,OV,LP, etc. over ten alarm lamps

-

frequency:

-

auto tracking

-

technology:

-

IGBT module

-

market:

-

Asia, Africa, south america, middle east, europe

-

induction coils:

-

customized coils

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

yongda

-

Weight (KG):

-

135

-

Marketing Type:

-

Hot Product 2024

-

Core Components:

-

IGBT, Control board

-

name:

-

induction heating generator

-

usage:

-

hardening, forging, brazing,annealing ,melting

-

processing work piece:

-

gear, shaft, steel rod, billets ,copper,aluminum

-

Color:

-

blue or black white

-

accessories:

-

induction coils

-

protect function:

-

OC,OV,LP, etc. over ten alarm lamps

-

frequency:

-

auto tracking

-

technology:

-

IGBT module

-

market:

-

Asia, Africa, south america, middle east, europe

-

induction coils:

-

customized coils

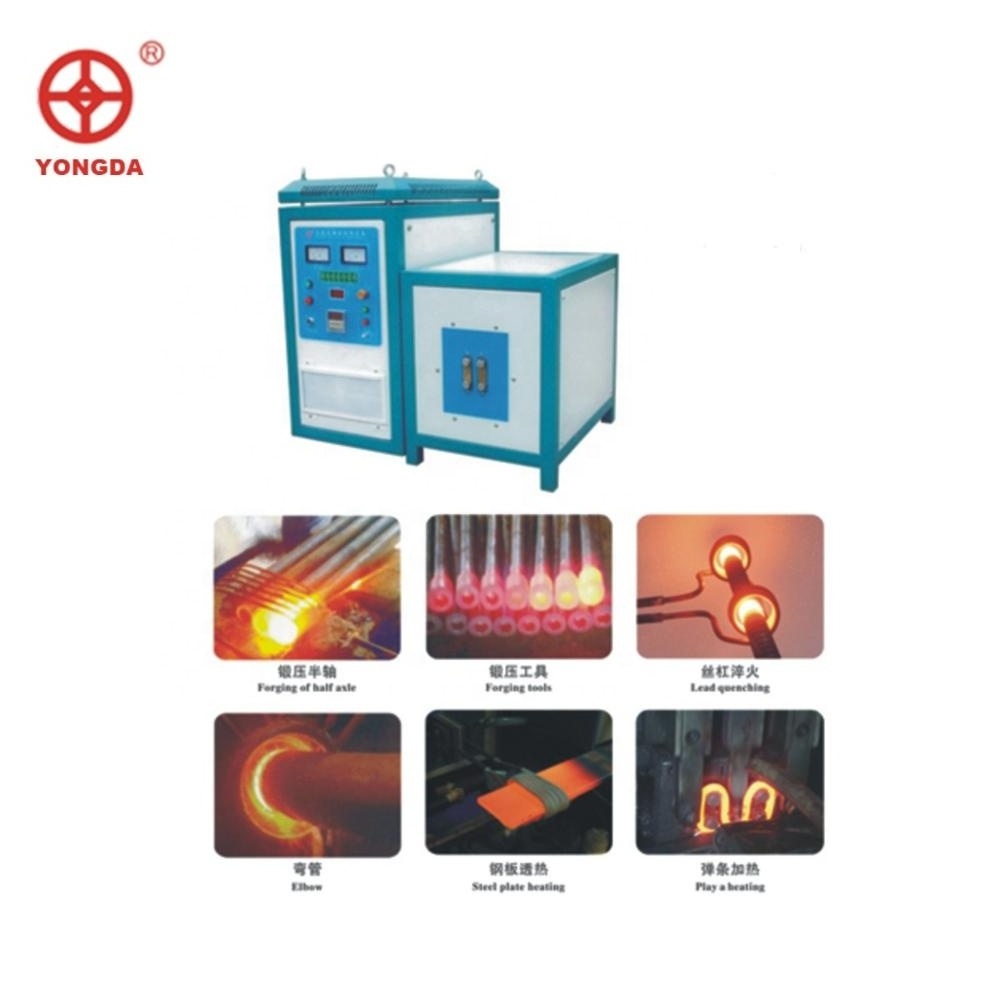

Introduction of induction heating generator/equipment/device/plant/machine:

YONGDA high frequency equipment is a device adopt for modern electronic module as key part of converter, through convert 50/60Hz power current into current with at different frequency band, which produces strong electromagnetic field in inductor to heat metal in a very short time. it can widely used in hardening, brazing, forging, melting, annealing, and some other industrial metal heating process.

Advantages of induction heating generator/equipment

1. The machine adopts IGBT modules (Siemens, Germany), high efficiency, energy saving.

2. Environmental. Almost no oxide layer, produced no exhaust, no waste-water is generated.

3. Heating fast and uniform.

4. A unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

5. Easy installation, simple operation.

6. Safe and reliable. No high voltage, very safe for operating people.

7. Machine power can be adjust step-less.

8. It has complete self-protect functions: such as many types of alarm lamps: over-current, over-voltage, over hot, water shortage etc, can also control and protect itself.

Technical parameters of induction heating generator/machine/plant

|

Model |

Input voltage |

Input current |

Oscillation frequency |

Cooling water pressure |

|

WZP-40 |

320-420V |

2-40A |

15-30KHZ |

0.1MPA |

|

WZP-60 |

320-420V |

3-60A |

15-30KHZ |

0.2MPA |

|

WZP-90 |

320-420V |

4-90A |

15-30KHZ |

0.3MPA |

|

WZP-120 |

320-420V |

6-120A |

15-30KHZ |

0.3MPA |

|

WZP-160 |

320-420V |

6-160A |

15-30KHZ |

0.3MPA |

|

WZP-200 |

320-420V |

6-200A |

15-30KHZ |

0.3MPA |

|

WZP-300 |

320-420V |

6-300A |

15-30KHZ |

0.3MPA |

|

WZP-400 |

320-420V |

6-400A |

8-15KHZ |

0.3MPA |

|

WZP-500 |

320-420V |

6-500A |

8-15KHZ |

0.3MPA |

Induction heating machine mainly used for forging,hardening, annealing, tempering, brazing, melting for many kinds of metal materials, such as auto parts workpieces, pipes, tubes, wires, rebars, motorcycle parts, camshaft, crankshaft, gear, axles, sprockets, etc. According to specifications of your workpiece requirement, we will offer you the best suitable machine.

1, forging, hot forming

A, all kinds of standard parts, fasteners, machinery parts, hardware tools, straight shank twist hot upsetting, hot.

B, metal heat annealing. Such as: tensile steel tube, pipe, smashed head; wire, heating wire nail; stainless steel annealed, rose type.

2, heat treatment,hardening,quenching

Various types of hardware, electrical, hydraulic, pneumatic components, automobiles, and motorcycle parts and other mechanical parts of the surface of the metal, bore, in part or in whole quenching. Such as: hammer, knife, scissors, pliers and various types of shafts, cams, sprockets, gears, valves, ball pin, large-scale Machine Tool, ductile iron quenching.

3, brazing,welding

Various types of carbide blades, turning, milling, planer, reamer, diamond saw blade, saw welding; grinding, drilling, cutting welding; brass, copper, stainless steel and other metal materials, the composite bottom of the pot Welding.

4, metal melting:

melting gold, silver and copper.

5, the other heated areas

Plastic pipe, cable, wire heating film; food, beverage, pharmaceutical industry uses aluminum foil.

Package & shipping of induction heating machine

1.Standard wooden case packaging.

2.Add foam for shockproof and add plastic film for waterproof.

3.Add steel belt and rivets fastening wooden cases.

4.The bottom pallet can bear 3 times weight than goods.

5.Transportation by sea,by air,by express DHL is available.

6.We will send you packaging photos, after goods sent from our factory.

7.Warranty: 12 months free replacement spare parts.

8.Manuals: operating and maintenance instructions,Troubleshooting Guide, Equipment inspection certification, warranty card,factory packing.

Service of YONGDA induction heating equipment/generator/plant:

1. Reply your inquiry within 24 hours.

2. Recommend suitable machine model,according to your work piece specifications and heating requirements.

3. Send detailed product parameters, photos and price.

4. Solve all the problem , such as shipping cost, shipping time,delivery time, warranty etc,what you concerned.

5. Produce induction heating equipment strictly based on the PI/contract.

6. About installation: provide install technical skecth, install and operating instruction, or send engineer to helps if need.

7. Tracking goods and help you install and operating machines.

8. Offer 12 months free replacement spare parts and Provide long-terms technical supporting.

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu 466300 , Zhoukou City.

We professionally dedicated to R&D, production of induction heating machine (high frequency, medium frequency ,super audio frequency) , used for forging, hardening, brazing,annealing, melting ,shrink fit, etc.

We also produce CND quenching machine tool, automatic feeding machine, heat exchanger, automatic welding frame.

Our factory scene

Rated matching product: industrial chiller, closed cooling tower,temperature controller etc.

The MF.HF induction heating power is essentially a "converter." Its role is to converted 50KHZ AC power, into MF.HF energy. By sensors in the MF, high-frequency energy is coupled to the work piece. Non-contact heating. Thus it is widely used. Especially heating ferromagnetic material, the effect is very good.

Quality spare parts from famous manufacturer

YONGDA Brand induction heating machine adopt IGBT modules (Germany Siemens technology ),small size, light weight, fast heating, power consumption, cheap and quickly these advantages , won the lover from majority of users. Over the past decade, with the development of our company in high-frequency induction heating technology, applications expand, users are increasingly , our products gradually formed a relatively complete two series (WGH series, WZP series)

We are in india heat treatment exhibition

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2. How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free.

And we provide life long time technical support and other assistance.

3. How to install your machine?

We have paper installation instructions and videos, we will teach till you learn it.

4. Which export port you use?

Any China port, commonly we will use Shenzhen, Guangzhou, Hongkong port, it can appoint as you like.

5. How about the payment terms and delivery time?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 30% deposit, 70% before shipment. You can pay by T/T, L/C, Western Union or other ways.

The small machine delivery time is within 7 days, the bigger one takes about 15days, we will delivery goods on time.

6. Is your goods has ISO9001 or CE certificate?

Yes, all our goods has ISO and CE certificate. All machines are high quality goods.

7. What is your nature of your company: Dealer or factory?

We are manufacturer and have a big factory, warmly welcome to visit our factory and contact us.

Alice Ann

Mob:008618738125957

Email: aliceann(at)yongdagp.com

Welcome to send us inquiry!

Please wirte your requirements in the following blanks,and click "send" to us directly, we will reply you within 12 hours.