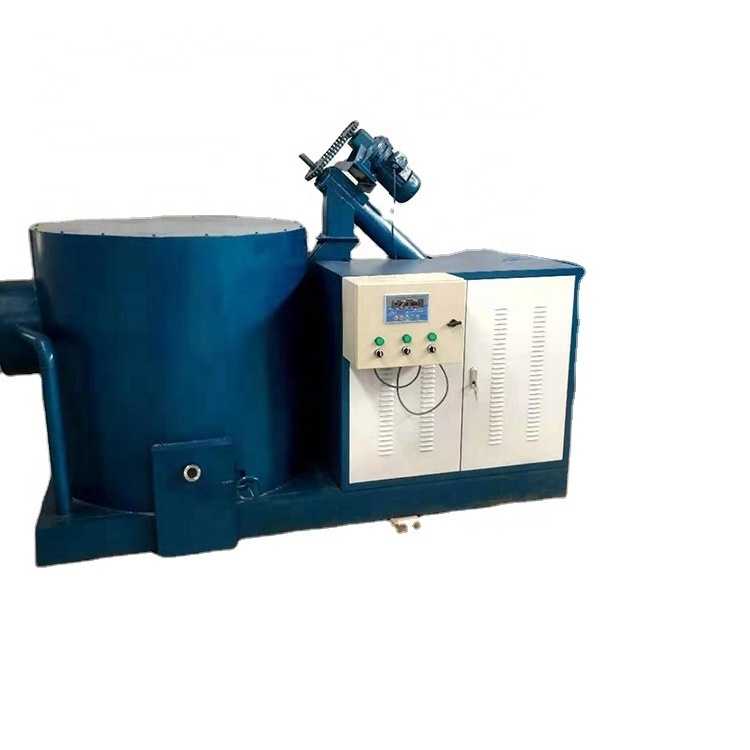

Biomass burner is a kind of biomass semi-gasification automatic control burner, biomass high temperature pyrolysis burner using

biomass particles, wood chips, wood powder, sawdust and other organic biomass as fuel, generally divided into air-cooled

combustion There are two models of engine and water-cooled burner.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

2600*1100*1600

-

Name:

-

Biomass Burner

-

Raw material:

-

Sawdust

-

Classification:

-

100,000 kcal,600,000 kcal,1 million kcal, etc.

-

Keyword:

-

Small Biomass Chip Burner Furnace

-

Application:

-

Industrial Boilers

-

Usage:

-

Heater

-

Function:

-

House Electricity Bill Saving

-

Type:

-

Biomass Fule Briquetting Machine

-

Other name:

-

Alternative Energy Generator

-

Main functions:

-

Provide Fuel Gas

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Aolai

-

Voltage:

-

380V

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

2600*1100*1600

-

Name:

-

Biomass Burner

-

Raw material:

-

Sawdust

-

Classification:

-

100,000 kcal,600,000 kcal,1 million kcal, etc.

-

Keyword:

-

Small Biomass Chip Burner Furnace

-

Application:

-

Industrial Boilers

-

Usage:

-

Heater

-

Function:

-

House Electricity Bill Saving

-

Type:

-

Biomass Fule Briquetting Machine

-

Other name:

-

Alternative Energy Generator

-

Main functions:

-

Provide Fuel Gas

Products Description

Use range:

Product Specification

|

Product model: 600,000 kcal

|

|

Rated voltage: 380V/220V

|

|

Rated power: 2.2KW

|

|

Applicable fuel: biomass pellets/Wood chips, rice husks, sawdust and so on

|

|

Full load consumption: 150kg

|

|

Fuel specification: &6-&8x30mm

|

|

Nozzle diameter: 168mm(Nozzle diameter: 168mm)

|

|

Shipping weight: 900kg

|

|

Dimensions: 1800*900*1400mm

|

|

The center of the crater is 95 cm from the ground, there are height adjustment wheels, and the size can be customized

|

Technical advantages

1. Renewable biomass energy can be used as fuel to realize sustainable use of energy, no tar, no waste water discharge, and meet GB132171 soot emission requirements. Avoid secondary pollution.

2. High thermal efficiency; using high-temperature phyrolysis combustion technology, coupled with a special air distribution design, continuous feeding, high thermal efficiency.

3. Stable; equipped with anti-tempering device, the inner tank is made of high-temperature resistant high-alumina bricks with a special process to build the outer high-temperature aggregate at one time, which truly realizes double-layer protection and makes it stronger and more durable.

4. Low carbon and energy saving; low smoke and dust, sulfur and nitrogen emissions, zero carbon dioxide emissions, operating costs are 40-60 lower than fuel and gas.

5. Simple operation; intelligent control, automatic feeding, wind dust removal, reduce labor intensity, simple operation, convenient maintenance, small workload, no need for special personnel

Our Company

Packaging And Shipping

Our Service

Before sale

1. Quick response

2. Professional technical consulting services

3. Provide a variety of related information about the product

On sale

1. Delivery on schedule

2. Strict factory acceptance

3. Use negotiated or suitable packaging for transportation

After sale

1.24 hours technical support

2. Long warranty

3. Sufficient spare parts guarantee

FAQ

1: What kind terms of payment can be accepted?

A: For terms of payment, L/C, T/T, D/A, D/P, Western Union (can be) could accepted

2: What certificates are available in Machinery?

A: For the certificate, we have CE, ISO,EPA(USA),CCC

3: What about the delivery time?

A: 7-20 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment or 2000 working hours, whichever occuts first.

5. What about the Minimum Order Quantity?

A: The MOQ is 1 pcs

6.What about the service?

1). Quick response to every inquiry.

2). Professtional and detailed answer to any of customer's questions.

3). Strict QC and in time delivery.

4). Offer all relative material for customer to know and better use the machine.

5). Periodically after service follow up, offer any necessary support if needed.

6).For the new machine, within determined limits, the manufacture guarantees warranty for a period of 12 months after bought or 20

00 working hours(whichever comes first).

7).The warranty includes repairation or replace the parts for free which were proved to be defective in origin by the technical

department of the manufacture.

8).The repairation or replacement for the parts should not exceed the warranty period.

9).The warranty is valid on the condition of all the terms listed in the contract was observed.

Contact Us

Shandong Aolai Machinery Co., Ltd

Facebook: Michele chen

Email : a

13176189701

@hotmail.com

Hot Searches