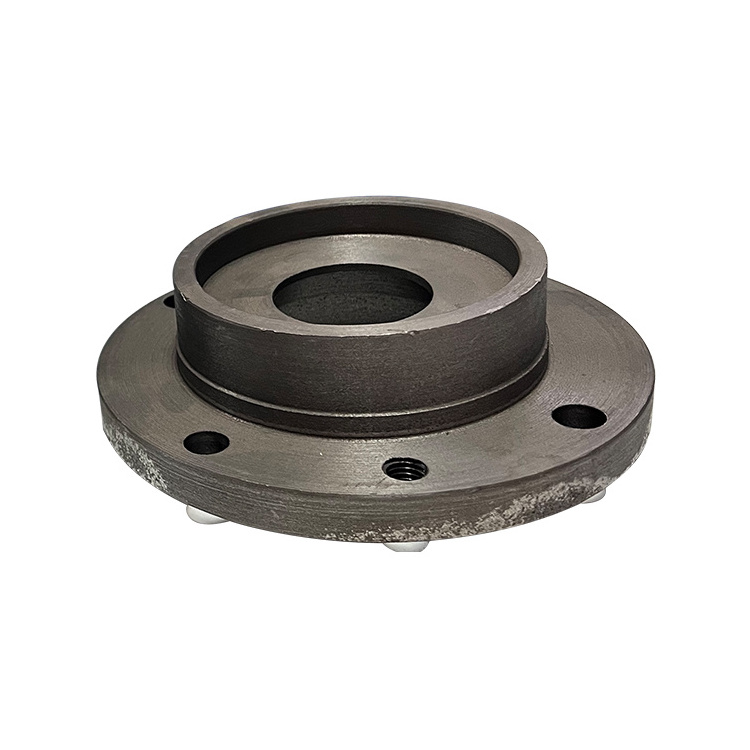

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Custom Iron Casting Parts

-

Material:

-

Customer's Requirements

-

Application:

-

Industry

-

Surface treatment:

-

Customers' Demand

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM\ODM

-

Technology:

-

Continual Casting,Lost Foam Casting,Low Pressure Casting,Sand Casting

-

Equipment:

-

Die-casting machine

-

MOQ:

-

1 Piece

-

Payment term:

-

30% in advance and 70% balance

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Fangzhuo

-

Model Number:

-

FZ-005

-

Product name:

-

Custom Iron Casting Parts

-

Material:

-

Customer's Requirements

-

Application:

-

Industry

-

Surface treatment:

-

Customers' Demand

-

Process:

-

Casting +Machining(if Need)+surface Treatment

-

Service:

-

OEM\ODM

-

Technology:

-

Continual Casting,Lost Foam Casting,Low Pressure Casting,Sand Casting

-

Equipment:

-

Die-casting machine

-

MOQ:

-

1 Piece

-

Payment term:

-

30% in advance and 70% balance

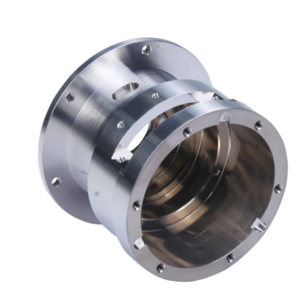

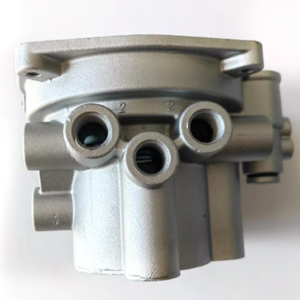

ALUMINUM CASTING PART

SHANDONG FANGZHUO FABRICATION CO.,LTD.

山东方卓精工机械有限公司

Product Overview

Shandong Fangzhuo Fabrication Co.,Ltd, was established in December 2018 with more than 100 employees, located in the Economic De-velopment Zone of Qihe County, Dezhou City, Shandong Province. We have anannual output of 7 thousand tons of processing capacity, mainly engaged inconstruction machinery, engineering equipment, CNC/laser machine tools andother important equipment mechanical parts forming and automation integra-tion.

Our products mainly include engineering machinery accessories, engineer-ing equipment accessories, all kinds of machine tool accessories processing and manufacturing. With the help of computer technology, we have formed a sef of management systems from product drawings toproduction quality tracking, from financial

control to material consumption, fromproduct market development to sales and after-sales service, and a set of hori-zontal to edge

and vertical to the end.

control to material consumption, fromproduct market development to sales and after-sales service, and a set of hori-zontal to edge

and vertical to the end.

|

Product Name

|

Casting Metal Part

|

|

Surface Treatment

|

Painting,Sandblasting,Galvanizing,Oiled,Cleaning,Polishing,Grinding, Polishing, Brushing

|

|

Material

|

Iron/Steel/Aluminum/Copper/Zinc/Magnesium/Titantium etc.,

|

|

Casting Type

|

Ordinary sand castings, metal mold castings, die castings, centrifugal castings, continuous castings, investment castings, ceramic

mold castings, electroslag remelting castings, bimetal castings |

|

Drawing Format

|

STEP/STP/IGS/X-T/STL/CAD/PDF

|

|

Application

|

Construction, hardware, equipment, machine tools, ships, aerospace, automobiles, locomotives,computers, electrical appliances,

lighting fixtures. |

|

Advantage

|

Corrosion Resistance, High Temperature Resistance, Low Temperature Resistance,

|

|

Processing Method

|

Casting/Milling/Turning/Polishing/Painting

|

|

Delivery Time

|

7-10 days

|

|

|

|

FAQ

Q1:What materials can you process?

Q3:How do you usually pack your products?

A3:We can provide packaging according to your requirements. Products with high appearance requirements will be packaged separately in blister boxes, and finally shipped in cartons or wooden boxes.

Q4:What surface treatment can you provide at present?

A4:Anode, electroplating, blackening, heat treatment, painting, etc.

Q5:Can you do die-casting, injection molding, stamping and sheet metal business?

A5:Yes, we can support all these processing.

Q6:Can you provide test reports and material certificates when shipping?

A6:Corresponding proof can be provided upon request.

A1:Brass, aluminum, stainless steel, mild steel, alloy steel, POM, PEEK, Kovar and other metal and non-metal materials

.

Q2:How long is your delivery time?

A2:This depends on the product and quantity, the general sample lead time is 7-10 days, and the mass production lead time is 15-30 days

A2:This depends on the product and quantity, the general sample lead time is 7-10 days, and the mass production lead time is 15-30 days

Q3:How do you usually pack your products?

A3:We can provide packaging according to your requirements. Products with high appearance requirements will be packaged separately in blister boxes, and finally shipped in cartons or wooden boxes.

Q4:What surface treatment can you provide at present?

A4:Anode, electroplating, blackening, heat treatment, painting, etc.

Q5:Can you do die-casting, injection molding, stamping and sheet metal business?

A5:Yes, we can support all these processing.

Q6:Can you provide test reports and material certificates when shipping?

A6:Corresponding proof can be provided upon request.

Hot Searches