- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xingxing

-

Model Number:

-

Ceramic Media Medium Cut

-

Use:

-

deburring, edge radiusing, descaling

-

Name:

-

Ceramic Media

-

Color:

-

Grey

-

Application:

-

deburring, edge radiusing, descaling

-

Shape:

-

ACT, SCT, CW

-

Feature:

-

Long Life

-

Size:

-

Customer Size

-

Density:

-

2.40-2.51g/cm3

-

Package:

-

25 Kg/bag

-

Hardness:

-

2.5-3.0

-

MOQ:

-

500 Kgs

Quick Details

-

Type:

-

Mass Finishing Media

-

Abrasive Grain Sizes:

-

80#-150#

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Xingxing

-

Model Number:

-

Ceramic Media Medium Cut

-

Use:

-

deburring, edge radiusing, descaling

-

Name:

-

Ceramic Media

-

Color:

-

Grey

-

Application:

-

deburring, edge radiusing, descaling

-

Shape:

-

ACT, SCT, CW

-

Feature:

-

Long Life

-

Size:

-

Customer Size

-

Density:

-

2.40-2.51g/cm3

-

Package:

-

25 Kg/bag

-

Hardness:

-

2.5-3.0

-

MOQ:

-

500 Kgs

Product Description

Mass finishing is a process which conditions the surface of a part for its ultimate intended use.Consequently,a process which causes a planned effect to a part's surface,or creates,prepares the surface of a part so as to assist or completely achieve the final desired quality without changing the basic shape of the part,can be described as mass finishing.

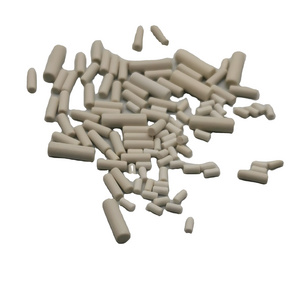

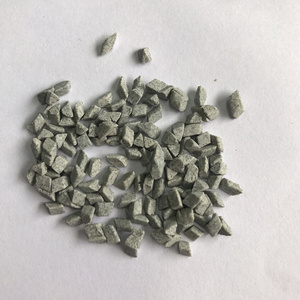

Ceramic media is a preformed tumbling media for deburring, polishing, radiusing, cleaning and de-rusting. This material can be shaped in a variety of shape and size.Brown corundum is the most common type of abrasive in the ceramic media. Besides, the abrasive content, abrasive grit size, as well as abrasive type, contribute to the ceramic media performance.

Different recipes are formulated for different industrial applications. Fast cutting, medium cutting, light cutting as well as slow-to-non cutting grade are the most common types.

Detailed Images

Ceramic media is one of the best general-purpose media. It is considered suitable for several different finishing applications including deburring, polishing, radiusing, cleaning and de-rusting. You can use it with workpieces of any composition or shape.

Our media

is of good quality. It will grind itself before shipment to ensure a certain smoothness. This ceramic media with low wear rate,it has the long life.

Size Information

|

Ball

|

Straight/angle cut triangle

|

straight/angle cut cylinder

|

Cone

|

Tri-star/Angle Tri-star

|

Straight/angle cut ellipse

|

|

1-5

|

3x3 4x4

|

2x4 3x6

|

20x20

|

6x6

|

8x3x8

|

|

6-10

|

5x5 6x6

|

5x10 6x12

|

30x30

|

10x10

|

10x5x10

|

|

11-15

16-20

|

8x8 10x10

12x12 15x15

20x20 25x25

|

8x15 10x15

12x25 15x25

|

40x40

|

15x15 20x20

|

15x7x15

25x10x25

|

|

21-25

|

30x30 35x35 40x40 45x45

|

16x30 20x40

35x40

|

|

22.23x9.53

28.58x9.53

|

28x15x28

|

Remark

:Customer's special needs for media is cared upon request.

Related Products

Xingxing service

Trial test service

Xingxing Abrasive will process samples parts from customers and recommend the proper equipment all at no charge to customers.Just send us samples with an explanation of your desired finish and we will process them in our lab,then send back samples within 3 working days.You will see the way our machines handle deburring ang polishing process!If you are satisfied with the finishing effect,we will trial test the samples parts till your confirmation.

After sales service

1. Provide user tracking service to record users' problems at any time and solve them as soon as possibl

e. After the completion of the order, users will be checked irregularly.

2. Regularly introduce new products and new functions and technologies to users.

Packing&Shipping

Packing:

wood pallet

Suitable for sea shipping,

25kg per plastic woven bag, then 1000kg or 500kg in one pallet.

Certifications

Company Introduction

FAQ:

Q:How is Xingxing brand?

Xingxing Abrasive is the leading manufacturer of mass finishing machinery and consumable medias in China.

- Provincial High-Tech enterprise

- More than 24 years of expertise in this field.

- 21000 square meters of factory area size.

-7250 tons/year of consumable medias production output

-1030 sets/year of mass finishing machinery production output

Q: How far is it from Shanghai or Hangzhou?

- Close to Shanghai, 2.5-3 hours of ride.

- Close to Hangzhou, 1 hour ride.

Q: What Certifications do you have?

ISO9001, ISO140001,CE, SGS(Rohs) certifications etc.

Q: What is machinery and consumble medias warranty?

- 2 year warranty for standard machinery.

- 1 year warranty for customized equipment.

- Consumble medias warranty as standard international brand media for quality lifetime consideration.

Q: What service we can offer?

- OEM/ODM product Manufacturing service.

- Trial test service, and professional advice for specific workparts surface finishing needs.

- Inquiry replied within 8 hours.

- Aftersales service starts from delivery stage, receiving stage, standard operation guide, problem shooting & fixing, regular

maintenance guide, spare parts providing, Machine lifetime maintenance service.

- Sample available for consumable medias.

Q: How you guarantee consumable (tumbling) media quality?

- Mature consumable media formula, highly acknowledged by overseas customers for more than 15 years.

- From raw material QC check to final products check before delivery.

- Extremely test conditioned for final products of every batch, and file data kept for monitoring.

- The test method is similar to Japan and USA standards.

- If quality test result doesn’t meet customer’s standard, we will do the internal rejection and remaking step scheduled as

priority.

Q: How you guarantee the mass finishing machinery quality?

-From raw material QC check to final products check before delivery.

-Standard machinery, we do the extremely test conditioned running for 24 hours continuously.

- OEM machinery, test method instructed by customers.

- ODM machinery, test method instructed by customers.

Q: What is your international term?

- CIF destination port or location of customer side.

- FOB Shanghai/Ningbo

- EXW/FCA

Q: What is your Payment method?

- T/T (Bank transfer) payment,as prepayment rate discussed.

- For bulk order, we can accept L/C at sight.

Q: What is your Minimum order amount?

- MOQ for machinery is 1 set.

- MOQ for consumble media is 500kg as one wooden pallet.

Q: What is your way of packaging?

- Fumigation wooden pallets for medias, 1000kg per pallet, 25kg/plastic bag.

- Fumigation wooden case for mass finishing machinery.

Q: How long is your production time?

- Generally, it will take 5-40 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

- 5 working days for stock available machine and medias.

- 25-30 days for machinery.

- 25 days for customized medias.

- 30-40 days for ODM machine or customized machinery, not including the automatic surface finishing system.

Q: What is the nearest Port? Shipping methods?

- Sea port: Shanghai, Ningbo.

- Railway departure station: Suzhou, Shanghai, Yiwu.

- Airport departure station: Shanghai.

- Express: Fedex, or other international courier service available.

Our factory

Q:How is Xingxing brand?

Xingxing Abrasive is the leading manufacturer of mass finishing machinery and consumable medias in China.

- Provincial High-Tech enterprise

- More than 24 years of expertise in this field.

- 21000 square meters of factory area size.

-7250 tons/year of consumable medias production output

-1030 sets/year of mass finishing machinery production output

Q: How far is it from Shanghai or Hangzhou?

- Close to Shanghai, 2.5-3 hours of ride.

- Close to Hangzhou, 1 hour ride.

Q: What Certifications do you have?

ISO9001, ISO140001,CE, SGS(Rohs) certifications etc.

Q: What is machinery and consumble medias warranty?

- 2 year warranty for standard machinery.

- 1 year warranty for customized equipment.

- Consumble medias warranty as standard international brand media for quality lifetime consideration.

Q: What service we can offer?

- OEM/ODM product Manufacturing service.

- Trial test service, and professional advice for specific workparts surface finishing needs.

- Inquiry replied within 8 hours.

- Aftersales service starts from delivery stage, receiving stage, standard operation guide, problem shooting & fixing, regular

maintenance guide, spare parts providing, Machine lifetime maintenance service.

- Sample available for consumable medias.

Q: How you guarantee consumable (tumbling) media quality?

- Mature consumable media formula, highly acknowledged by overseas customers for more than 15 years.

- From raw material QC check to final products check before delivery.

- Extremely test conditioned for final products of every batch, and file data kept for monitoring.

- The test method is similar to Japan and USA standards.

- If quality test result doesn’t meet customer’s standard, we will do the internal rejection and remaking step scheduled as

priority.

Q: How you guarantee the mass finishing machinery quality?

-From raw material QC check to final products check before delivery.

-Standard machinery, we do the extremely test conditioned running for 24 hours continuously.

- OEM machinery, test method instructed by customers.

- ODM machinery, test method instructed by customers.

Q: What is your international term?

- CIF destination port or location of customer side.

- FOB Shanghai/Ningbo

- EXW/FCA

Q: What is your Payment method?

- T/T (Bank transfer) payment,as prepayment rate discussed.

- For bulk order, we can accept L/C at sight.

Q: What is your Minimum order amount?

- MOQ for machinery is 1 set.

- MOQ for consumble media is 500kg as one wooden pallet.

Q: What is your way of packaging?

- Fumigation wooden pallets for medias, 1000kg per pallet, 25kg/plastic bag.

- Fumigation wooden case for mass finishing machinery.

Q: How long is your production time?

- Generally, it will take 5-40 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

- 5 working days for stock available machine and medias.

- 25-30 days for machinery.

- 25 days for customized medias.

- 30-40 days for ODM machine or customized machinery, not including the automatic surface finishing system.

Q: What is the nearest Port? Shipping methods?

- Sea port: Shanghai, Ningbo.

- Railway departure station: Suzhou, Shanghai, Yiwu.

- Airport departure station: Shanghai.

- Express: Fedex, or other international courier service available.

Our factory

The mass finishing media is sintered through the tunnel kiln.We own two tunnel kilns,each of it is made up of high temperature sintering tunnel kiln and heating tunnel kiln.The nature gas tunnel kiln has the advantage of energy saving,easy control sintering temperature,non-stop production,short cycle of sintering,stable working condition,and more production capacity.

Our laboratory

Please contact us!

Hot Searches