- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Packing Machine

-

Usage:

-

Plastic Packaging

-

Material:

-

Stainless Steel

-

Bottle type:

-

Galss Bottle

-

Filling speed:

-

800-1200 Bottle/min

-

Feature:

-

High Efficiency

-

Machine type:

-

Filing Capping Machine

-

Power supply:

-

3Ph 380V 50/60HZ

-

Filling volume:

-

200-1000ml

Quick Details

-

Packaging Material:

-

Plastic, Metal, Glass

-

Place of Origin:

-

Shanghai, China

-

Function:

-

Automatic Filler

-

Product name:

-

Packing Machine

-

Usage:

-

Plastic Packaging

-

Material:

-

Stainless Steel

-

Bottle type:

-

Galss Bottle

-

Filling speed:

-

800-1200 Bottle/min

-

Feature:

-

High Efficiency

-

Machine type:

-

Filing Capping Machine

-

Power supply:

-

3Ph 380V 50/60HZ

-

Filling volume:

-

200-1000ml

tom yum paste jam filling machine production line

whatsapp/wechat/viber/mobile:008618017922132

Descriptions:

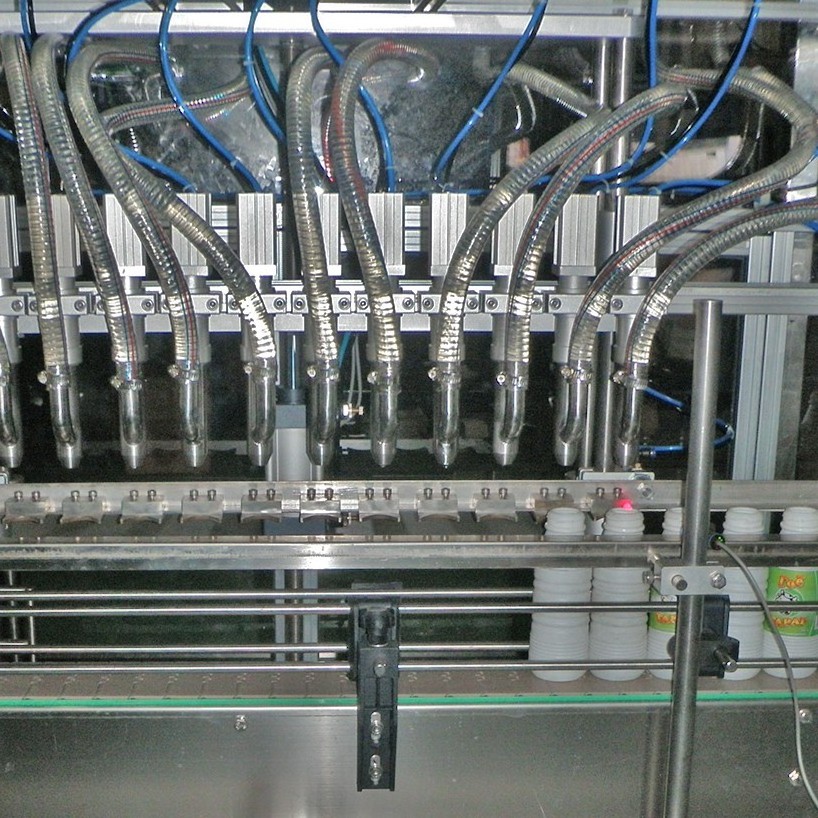

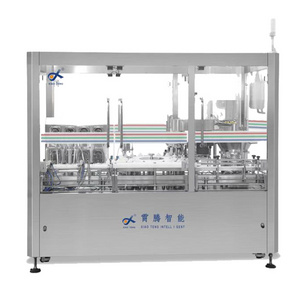

This Automatic organic tahini sauce filling machine is a multifunctional high-speed full automatic machin,including specially designed for jam or other liquid(such as water,milk.oil,juice,honey) to be filled and sealed.

The machine applied with world famous electrical.High quality,high stablity,long sevice line.All the parts of machine are made of high quality stainless steel.

automatic filling machine

Features:

1. Vacuum Preventing Leaking System

2. No Bottle or Lack of Bottle, No Filling System

3. Photoelectric Sensor, Mechatronics Filling Adjustment System

4. Photoelectric Sensor, Material Level Control Feeding System

5. Stainless Steel Frame, Plexiglass as Security Cover

6. Control System: PLC/Electronic-Pneumatic Controlled

7. Operation Panel: "Intelligent" Colorful Touch Screen

8. Filling Accuracy:+-0.5%

9. Capacity Adjustment:All cylinders adjusted automatically combine single cylinder adjusted individually.

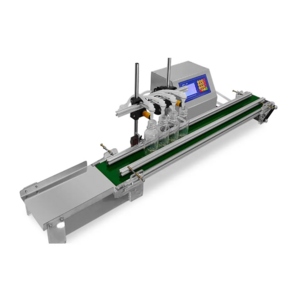

10. Container transport:Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor.

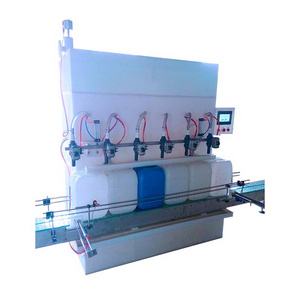

Technical Parameters:

|

Model |

LW--4A |

|

Filling Volume |

500ml can customize |

|

Air Pressure |

3-5kg/cm2 |

|

Total Power |

AC380V, 50/60HZ |

|

Capacity |

0--1920 bottles/h customize |

|

Filling Heads |

4 |

|

Material |

SUS304 |

Accessories list:

|

Accessories name |

Brand name |

|

PLC |

Siemens German |

|

electrical elements |

Schneider France |

|

pneumatic element |

AirTac Taiwan |

|

amphenol connector |

Weidmuller German |

|

Transducer |

Danfoss Denmark |

|

Bearing |

IGUS German |

|

Photoelectricity |

KEYENCE Japan it is waterproof |

|

Piston |

Taiwan, heat-resistant, oil proof |

Company information:

Shanghai leadworld machinery technology Co.,ltd is specialized in development researching and manufacturing variouspacking production systems,The filling machine is designed for bottles,filling machine for cans,packingaging machine,labeling machine,sealing machine,capping machineand so on.They have well-equipped testing equipment and etrong technical force.

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs.

Certifications

FAQ

Q:Are you manufacturer?

A:Yes,we are manufacturing filling machine with rich experence,our Engineer Team with over 20 year' experience.

Q:How can I know your machine has good quality?

A:We will send the video of testing the machine working condiion for you before delivery,so you can send us your bottle samples for a trial.

We can do whole line producing: