1

.Using unique design,avoid the traditional bottle on rubber clip to block the bottle threade

d parts m

ay be caused by the pollution.

2

.Washing pump is made of stainless steel.

3

. By high spray nozzle, blunt bottle of water jet angles, flush to the bottle of any part of the inner wall, rinse with water thoroughly and save flush bottle.

4

. Bottle clamp and flip agencies sliding sleeve adopts Germany Igus corrosion resistant bearing without maintenance.

- Product Details

- {{item.text}}

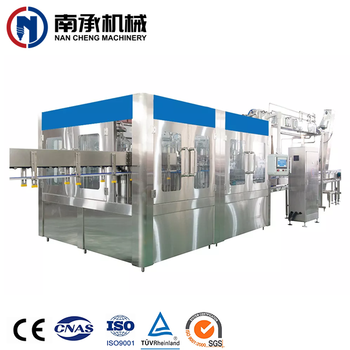

Quick Details

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

nancheng machinery

-

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weight:

-

6500 KG

-

Product name:

-

Soft Drink Filling Machine

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

water, Carbonated soft drink,CSD,juice,etc

-

Bottle type:

-

pet/plastic bottle

-

Material:

-

Stainless Steel 304/316

-

Filling type:

-

High Precision Filling Level

-

Capacity:

-

1000-24000bph

-

Filling volume:

-

200 -- 2000ML

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

20 Years Experiences

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, Other, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Water, Juice

-

Filling Accuracy:

-

99.9%

-

Voltage:

-

220/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

nancheng machinery

-

Dimension(L*W*H):

-

3880*2800*2500mm

-

Weight:

-

6500 KG

-

Product name:

-

Soft Drink Filling Machine

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

water, Carbonated soft drink,CSD,juice,etc

-

Bottle type:

-

pet/plastic bottle

-

Material:

-

Stainless Steel 304/316

-

Filling type:

-

High Precision Filling Level

-

Capacity:

-

1000-24000bph

-

Filling volume:

-

200 -- 2000ML

-

Control:

-

PLC+ Touch Screen

-

Advantage:

-

20 Years Experiences

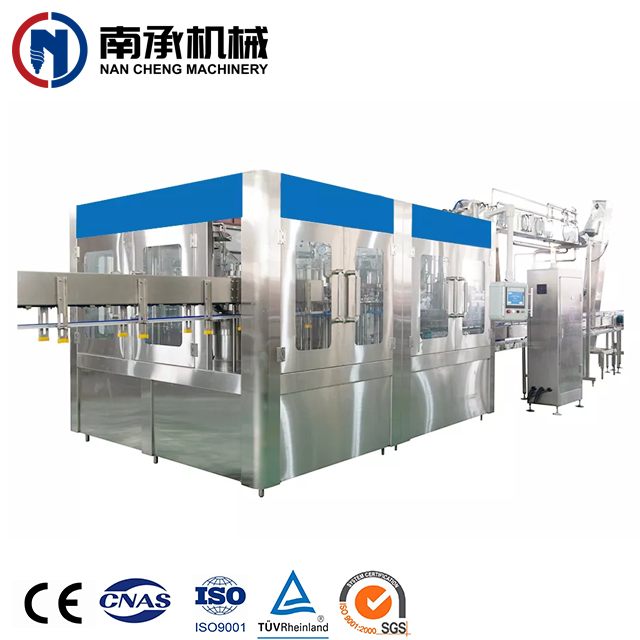

Product Overview

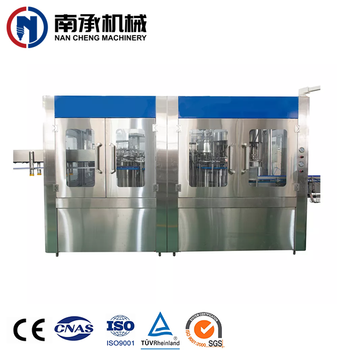

Fully Automatic Soda Drink Filling Machines

Introductions of soda drink filling machines. This type of machine is suitable for filling and sealing aluminum canned beer and carbonated soft drinks. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling repose fully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss. It can be equipped long-distance control system.

It is the preferred equipment for the medium beer and beverage plant. And we are able to provide the complete pop cans / tin can filling and package solution, from can depalletizer, can rinsing machine, can filling & sealing monoblock machine, leakage check, liquid nitrogen dosing machine, pasteurizer tunnel, blow dryer, carton package, film package system ,which is widely used for the beverage, beer, juice industry and so on.

It is the preferred equipment for the medium beer and beverage plant. And we are able to provide the complete pop cans / tin can filling and package solution, from can depalletizer, can rinsing machine, can filling & sealing monoblock machine, leakage check, liquid nitrogen dosing machine, pasteurizer tunnel, blow dryer, carton package, film package system ,which is widely used for the beverage, beer, juice industry and so on.

Product Description

Product Features

The series equipment is used in producing all kinds of carbonated or non-carbonated liquid with container Washing, filling,sealing and can carried out on the same machine.The design of the machine is scientific and reasonable.

A fully connected line helps you optimise performance and make smarter decisions across the lifetime of your line. Our holistic approach supports your need for increased flexibility and efficiency, with minimal waste, quick SKU changeovers and lower environmental costs. Reductions in resource consumption and bottle weight, consistent bottle durability and high efficiency are all achieved through careful packaging design, detailed equipment planning and a flexible line setup.

A fully connected line helps you optimise performance and make smarter decisions across the lifetime of your line. Our holistic approach supports your need for increased flexibility and efficiency, with minimal waste, quick SKU changeovers and lower environmental costs. Reductions in resource consumption and bottle weight, consistent bottle durability and high efficiency are all achieved through careful packaging design, detailed equipment planning and a flexible line setup.

|

Applicable Products:

|

Cola, soft drinks, gas soda, beer,energy drinking,etc.

|

|

Suitable Container:

|

POP Can, PET bottles and glass botttle of various shapes and capacities

|

|

Filling Mode:

|

Mechanical valve filling or electronic valve filling

|

|

Production Capacity:

|

1000 bottles/hour – 72000 bottles/hour

|

Product Paramenters

Details Images

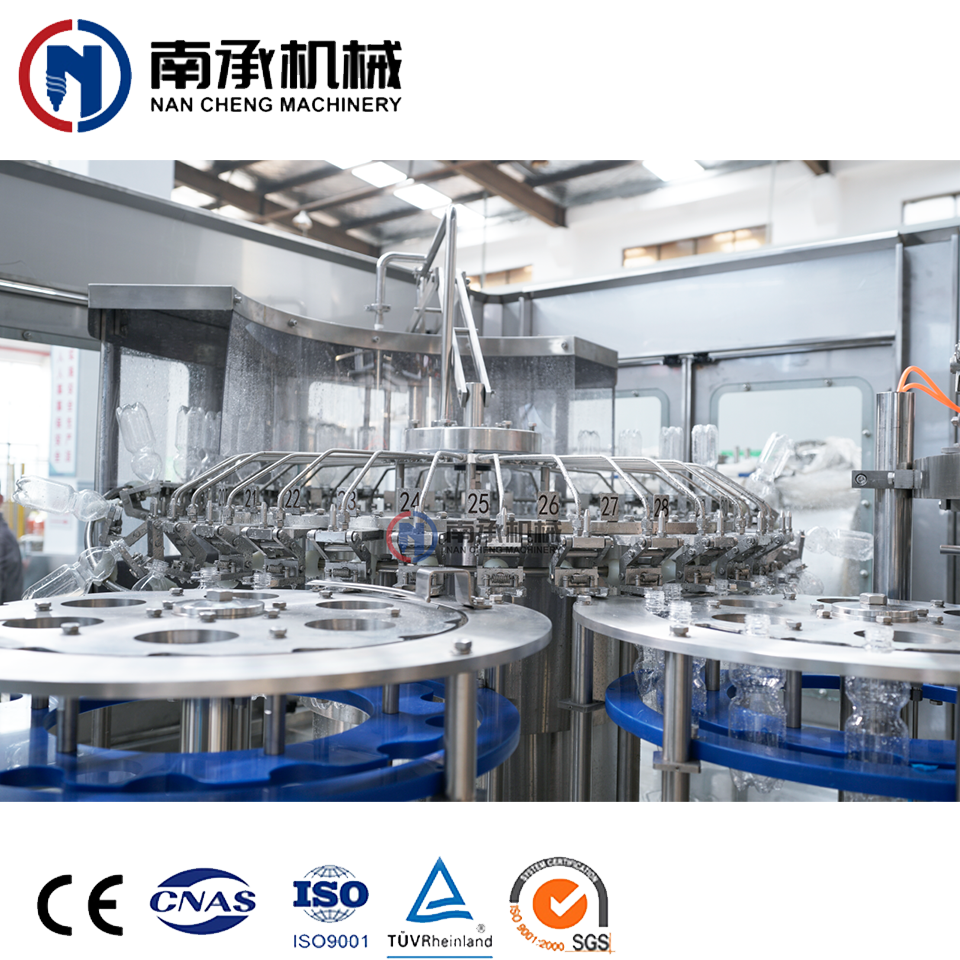

WASHING PARTS

FILLING PARTS

1

.Filling method for equal pressure filling.

2 .Filling valve manufactured SUS 304/316.

3 .High precision, high speed liquid filling.

4 .Filling move by the rack drive system through gear transmission.

5 .Hydraulic cylinder controlled by a float liquid level.

6. Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

2 .Filling valve manufactured SUS 304/316.

3 .High precision, high speed liquid filling.

4 .Filling move by the rack drive system through gear transmission.

5 .Hydraulic cylinder controlled by a float liquid level.

6. Using the latest double guide pillar type bottle of lifting mechanism, avoid the bottle of elevating the old products must be through the mesa caused by leakage on the edge, at the same time, easy installation and maintenance.

CAPPING PARTS

1

.Automatic check,no bottle no capping.

2 .Capping heads in stainless steel 304/316.

3 .Capping heads stop working when lack of bottle.

4 .Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5 .High efficiency centrifugal principle.

2 .Capping heads in stainless steel 304/316.

3 .Capping heads stop working when lack of bottle.

4 .Fall guy guide sets out to prevent the cover through and cover on the body, at the same time equipped with a set of photoelectric switch, automatic stop when lighted cover rail without cover machine, can effectively avoid the occurrence of open bottle.

5 .High efficiency centrifugal principle.

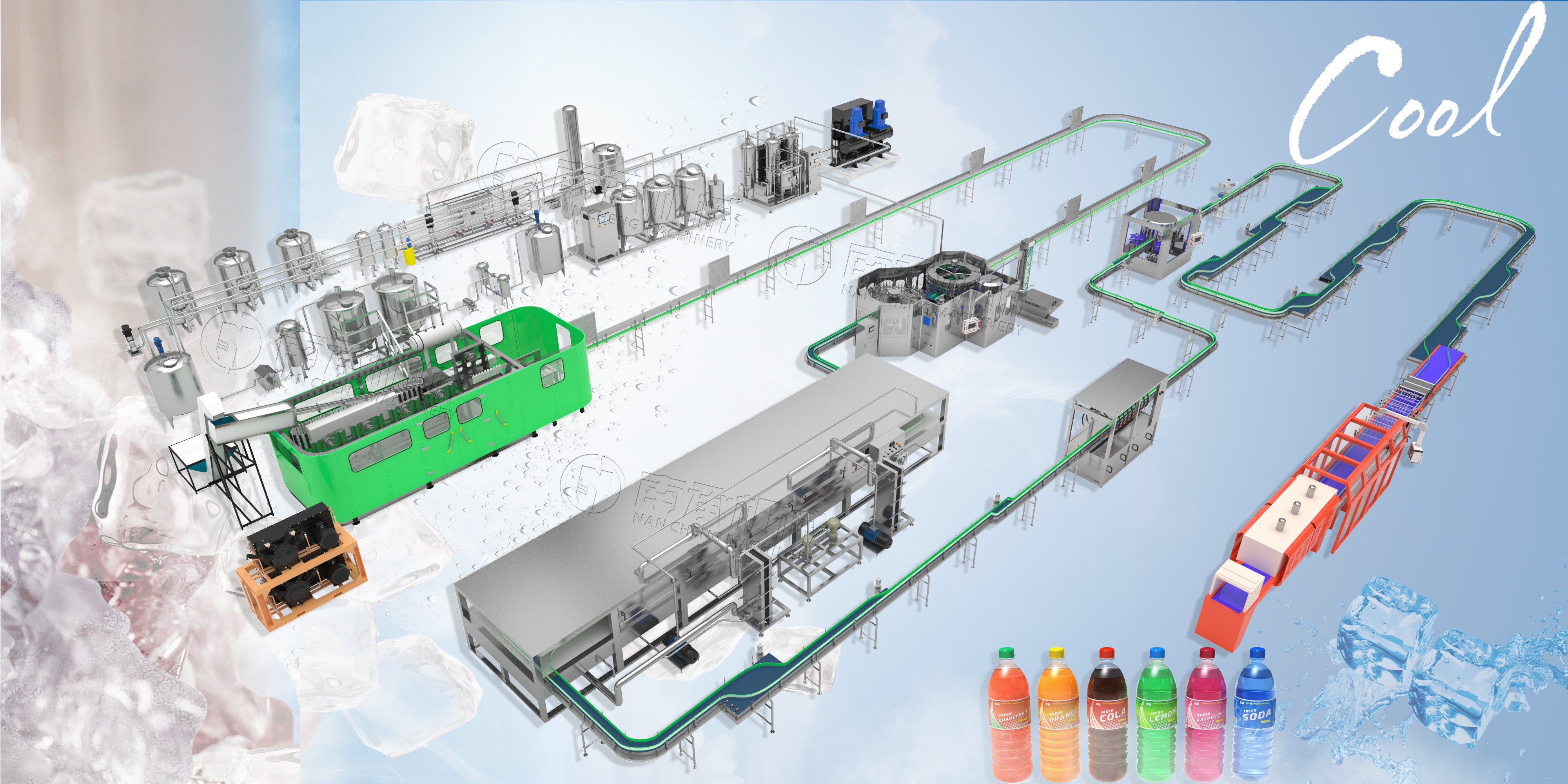

Production Process

Complete Carbonated Drinks Production Line

1. Water treatment system (quartz sand filter, active carbon filter,

sodium ion filter,

softner, RO system and so on)

2. Ozone generator sterilizer

3. Aseptic water storage tank

4. Sugar melting tank & syrup filter

5. Flavour blending tank & syrup cooler

6. Co2 drink mixer & Co2 filter

7. Water chiller

8. Auto bottle washing, filling and capping line

9. Labeling machine

10. Date of manufacture printer

11. Final products film packaging machine and so on.

1-Water Treatment System.

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

Benefits.

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

Benefits.

1 / Pack consistency and quality 2 / Gentle and precise infeed configuration

1 / Pack consistency and quality 2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple

Packaging combination

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

5 / Heat, glue, carton and film optimisation

\uD83D\uDC4DPET Bottle Water Filling Machine

\uD83D\uDC4DCarbonated Beverage Filling Machine

3-5 Liters Water Filling Machine

5 Gallon Water Filling Machine

\uD83D\uDC4DPure Mineral Water Treatment System

Glass Bottle Filling Machine

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines.

Hot Searches