Liquid silicone rubber, also known as LSR, is a type of silicone material that is in liquid form. It is made from a two-component

system that consists of a liquid silicone rubber base and a catalyst, which allows it to cure or solidify when exposed to heat.

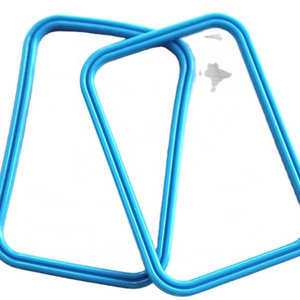

LSR has excellent properties such as high tear resistance, good elongation, and high temperature resistance. It is widely used in

various industries including automotive, electronics, medical, and consumer goods. Some common applications of liquid silicone

rubber include sealants, gaskets, o-rings, medical implants, and baby products such as bottle nipples and pacifiers.

system that consists of a liquid silicone rubber base and a catalyst, which allows it to cure or solidify when exposed to heat.

LSR has excellent properties such as high tear resistance, good elongation, and high temperature resistance. It is widely used in

various industries including automotive, electronics, medical, and consumer goods. Some common applications of liquid silicone

rubber include sealants, gaskets, o-rings, medical implants, and baby products such as bottle nipples and pacifiers.