- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZhongSu

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

20*2.5*2.5

-

Power (kW):

-

220

-

Weight:

-

20000 KG

-

machine:

-

wpc/pvc profile

-

Processing Type:

-

Extruding Machine

-

Product Type:

-

WPC PVC profile

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Fully Automatic

Quick Details

-

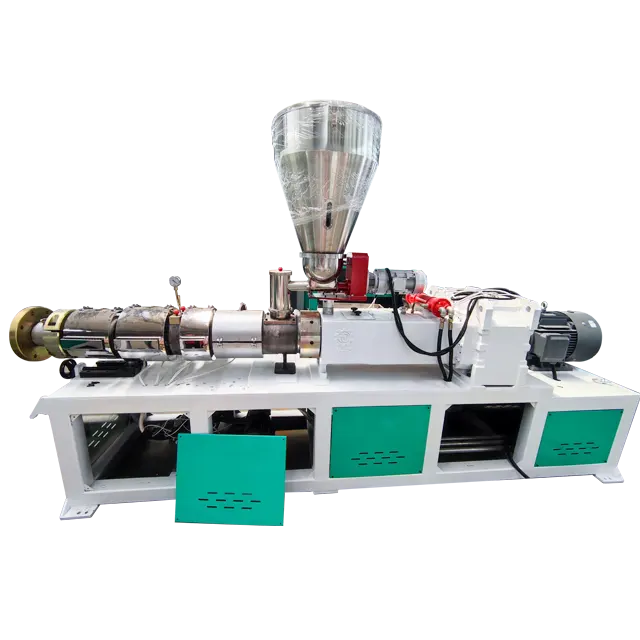

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

22:1

-

Screw Speed (rpm):

-

47 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ZhongSu

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

20*2.5*2.5

-

Power (kW):

-

220

-

Weight:

-

20000 KG

-

machine:

-

wpc/pvc profile

-

Processing Type:

-

Extruding Machine

-

Product Type:

-

WPC PVC profile

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Automatic Grade:

-

Fully Automatic

Product Description

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

Condition

|

New

|

|

Processing Type

|

Extruding Machine

|

|

Product Type

|

WPC PVC profile

|

|

Machine Type

|

wpc/pvc profile

|

|

Voltage

|

380V/220V

|

|

Dimension(L*W*H)

|

20*2.5*2.5

|

|

Power (kW)

|

220

|

|

Weight (KG)

|

20000 KG

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High-accuracy

|

|

Showroom Location

|

Pakistan, India, Turkey,Brazil

|

|

Applicable Industries

|

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing,Motor,Pump,Gear,PLC,Pressure vessel,Engine,Gearbox,Screw,Other

|

|

Screw Design

|

Double-screw

|

|

Screw Material

|

38CrMoALA

|

|

Screw diameter (mm)

|

65

|

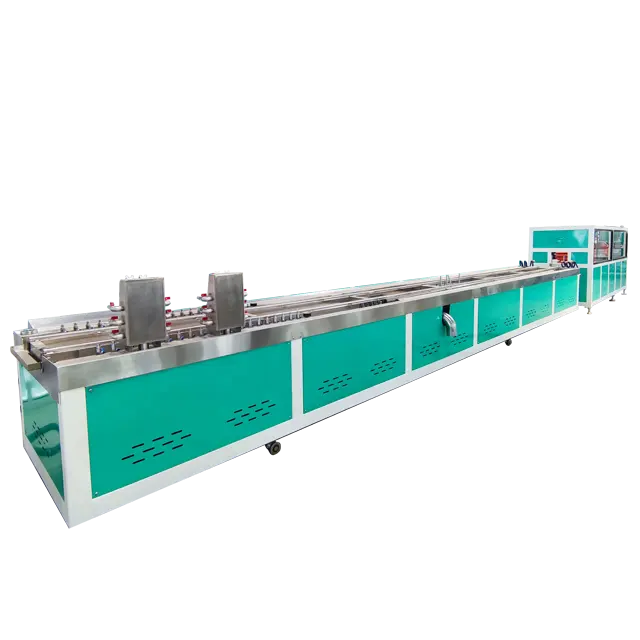

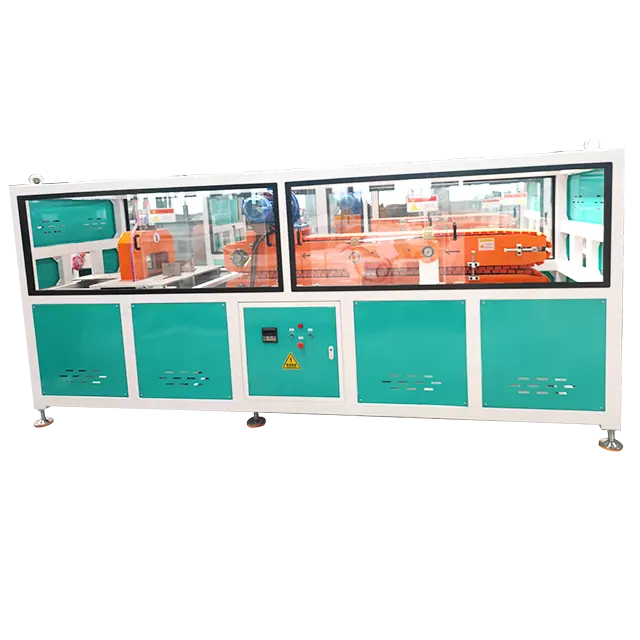

Characteristics of the equipment:

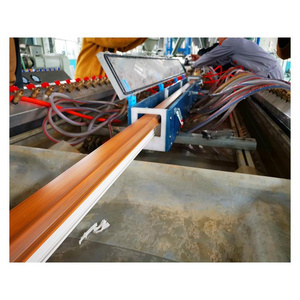

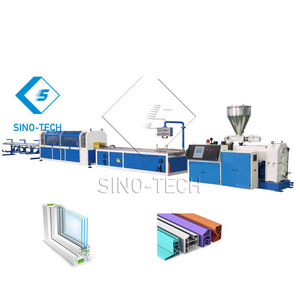

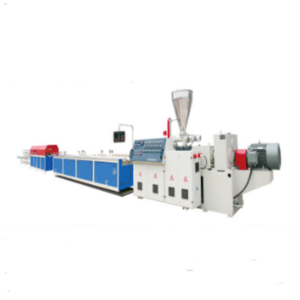

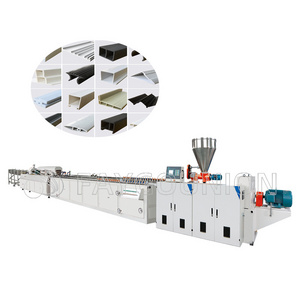

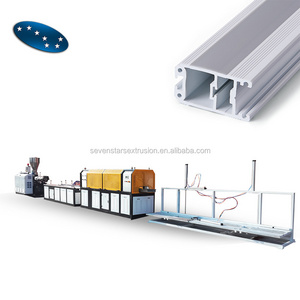

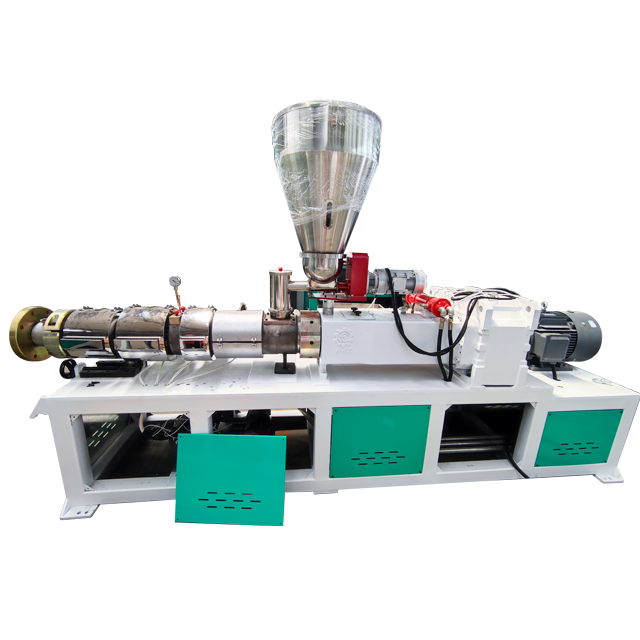

This production line can continuously produce PVC WPC profile,such as door frame and window profiles,wall panel,skirting etc.

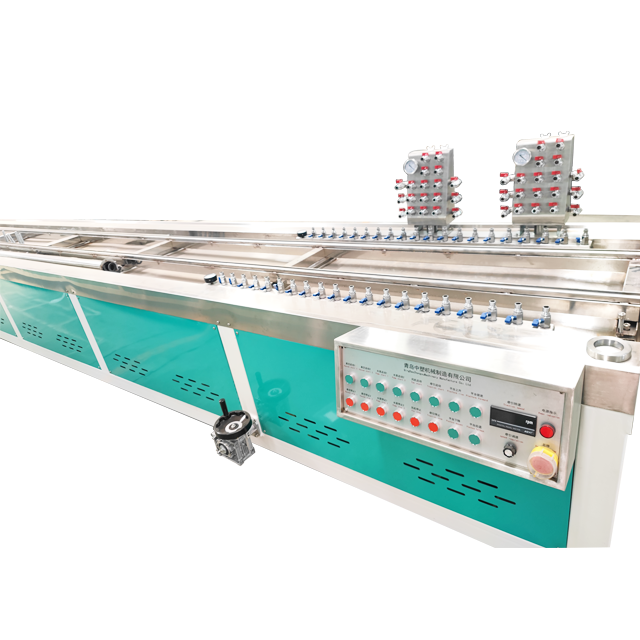

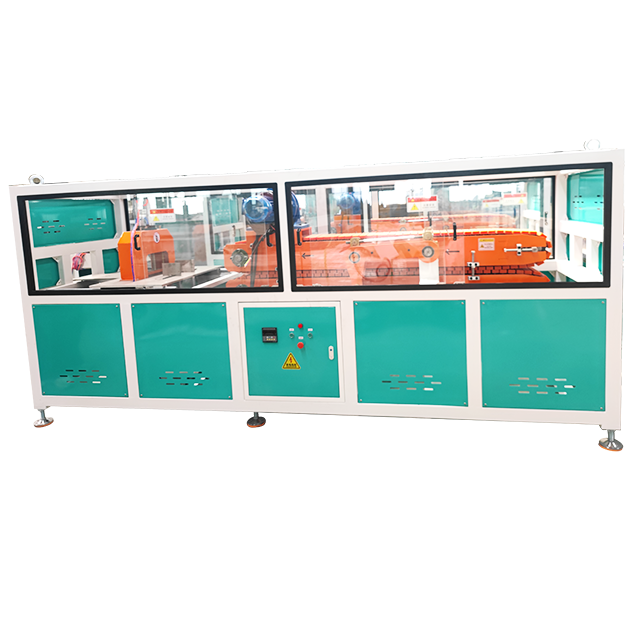

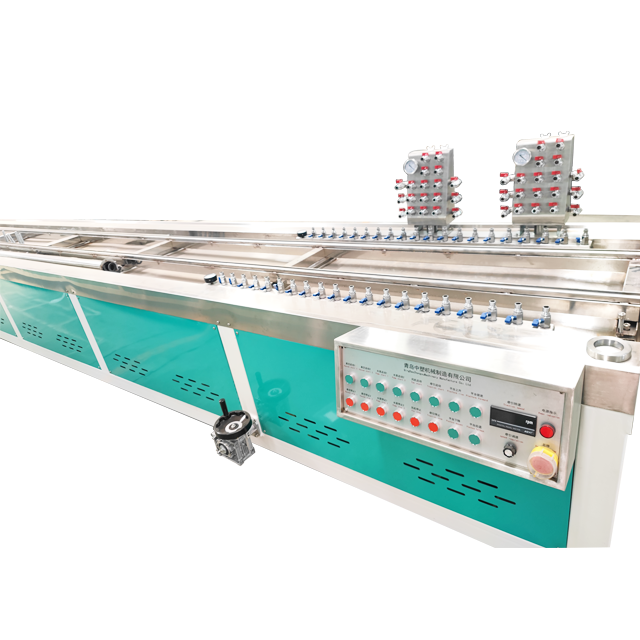

The production line consists of extruder,mould,calibrating platform,haul off and cutting machine and stacker.

This production line can continuously produce PVC WPC profile,such as door frame and window profiles,wall panel,skirting etc.

The production line consists of extruder,mould,calibrating platform,haul off and cutting machine and stacker.

The extruder can produce PVC or WPC material material profile by changing screw and mould.

The calibrating platform adopts two section structure and adopt double water tank to ensure the stability of machine in

production.

The haul off and cutting machine is one body struture ,the advantages of this unit are saving space and high precision cutting.

The calibrating platform adopts two section structure and adopt double water tank to ensure the stability of machine in

production.

The haul off and cutting machine is one body struture ,the advantages of this unit are saving space and high precision cutting.

Machine Production Process:

Production process of PVC plastic profile extrusion machinery and equipment: Proportioning and weighing according to the formula------ Screw feeding machine ------ High speed mixer unit High speed mixing ------ PVC raw materials are fully mixed in a hotmixer------ Low speed mixing in a cold mixer to 40~50 ° ------ Screw feeding machine ------ Conical twin screw extruder ------Extrusion through mold forming ------ Setting mold on the vacuum setting table is shaped through vacuum pumping and cooling water------Pulling Automatic traction of the traction machine, adjusting the speed of the traction machine ------- through the travelswitch for fixed length cutting and unloading the stack.

The production line can select different specifications of single or double screw extruders based on different profile sectionsand molds, and is equipped with corresponding auxiliary equipment such as vacuum molding tables, traction machines, cuttingmachines, and turning platforms.

The production line can select different specifications of single or double screw extruders based on different profile sectionsand molds, and is equipped with corresponding auxiliary equipment such as vacuum molding tables, traction machines, cuttingmachines, and turning platforms.

Equipment List

Final Product & Application

Packing & Delivery

PLASTIC FILM OR ACCORDING TO CUSTOMER'S REQUIREMENTS

Hot Searches