- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V or other

-

Dimension(L*W*H):

-

4500mm*700mm*900mm

-

Weight:

-

4 kg

-

After-sales Service Provided:

-

yes

-

name:

-

Roll Forming Machine

-

origin:

-

China

-

material:

-

ligtht steel

-

sprocket:

-

P-25.4

-

control system:

-

PLC

-

roller station:

-

11

-

daimeter of pricipal axle:

-

60mm

-

material of roller:

-

45# Cr plated

-

material of blade:

-

Cr12 mold steel

Quick Details

-

Type:

-

Chinese factory galvanized stud and track machine for sale

-

Tile Type:

-

Steel

-

Production Capacity:

-

0-60m/min

-

Rolling thinckness:

-

0.2-1.0mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HKY

-

Voltage:

-

380V or other

-

Dimension(L*W*H):

-

4500mm*700mm*900mm

-

Weight:

-

4 kg

-

After-sales Service Provided:

-

yes

-

name:

-

Roll Forming Machine

-

origin:

-

China

-

material:

-

ligtht steel

-

sprocket:

-

P-25.4

-

control system:

-

PLC

-

roller station:

-

11

-

daimeter of pricipal axle:

-

60mm

-

material of roller:

-

45# Cr plated

-

material of blade:

-

Cr12 mold steel

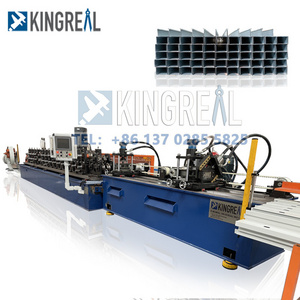

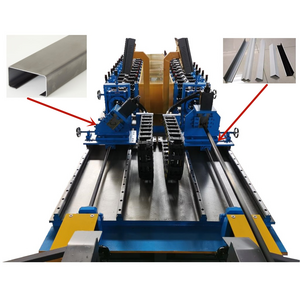

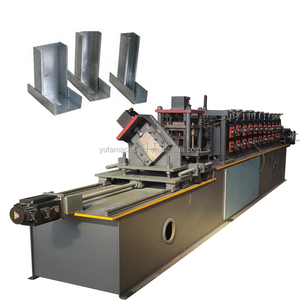

Furring channel ceiling keel forming machine stud track furring channel

1. Working Flow:

Decoiling--feeding---forming---cutting---finished product

2. Parts of Equipment:

Decoiler ,roll forming machine, hydraulic cutting (punching device),electric system(PLC control system),hydraulic system, stacker.

3. Techincal description

:

1).Automatic inner tight decoiler

a.coil inner diameter 450mm-550mm

b. maximum width of coiling600mm

c. maximum weight of loading 2500kg

2) . Main forming machine

a. number of forming steps 11rows

b. material of shaft 45# steel . Outer diameter 60mm

c.main motor power: 5.5kw

d. The speed of forming: 0-50m/min

3).Hydraulic cutter

a. material of blade:Cr12 mould steel with quenched treatment 60-62

b. cutting system :adopt advanced hydraulic drive, after forming automatic cut, no distort, no wasting , high safe factor.(tracking cutting)

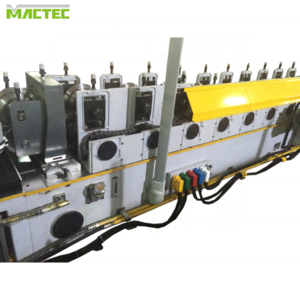

4).The electrical control system

a. The Brand of display: DELTA

b.The main computer (PLC): DELTA DVP14

5).Hydraulic system

a. Adopting advanced hydraulic system of Tai Wan

b. Power:3kw

6).The equipments coating , package

a.the coating adopt international general shade-guide

b.The package :simple waterproof package.