- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

51852-81-4

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jin Lu Yang

-

Model Number:

-

JLY-PU002

-

Product Name:

-

Oil-based Single Component Polyurethane Waterproofing Coating

-

Color:

-

colorful

-

Drying Method:

-

moisture cured

-

Technical Index:

-

JC/T864-2008

-

Substrate:

-

customized

-

Specification:

-

20kg/barrel

-

Method:

-

spray or brush

-

Colors:

-

black, red, green. grey

Quick Details

-

CAS No.:

-

51852-81-4

-

Other Names:

-

Powder Paint

-

MF:

-

(C10H8N2O2.C6H14O3)x

-

EINECS No.:

-

51852-81-4

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jin Lu Yang

-

Model Number:

-

JLY-PU002

-

Product Name:

-

Oil-based Single Component Polyurethane Waterproofing Coating

-

Color:

-

colorful

-

Drying Method:

-

moisture cured

-

Technical Index:

-

JC/T864-2008

-

Substrate:

-

customized

-

Specification:

-

20kg/barrel

-

Method:

-

spray or brush

-

Colors:

-

black, red, green. grey

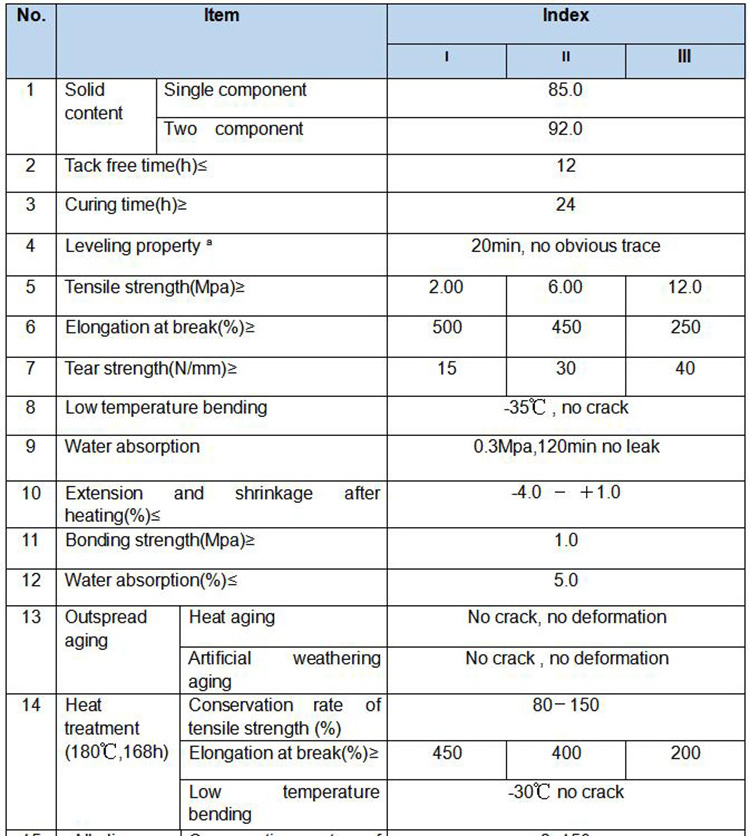

Oil-based Single Component Polyurethane Waterproofing Coating

Single component PU waterproof coating is a environment friendly elastic waterproof coating ,its basal component is polyether polyol.

| Product Name | Single Component Polyurethane Waterproof Coating |

| Size | 20kg/barrel |

| Color | black , red , blue ,or customized |

| Low temperature bending | -35° |

| Technical Index | GB/T19250-2013 |

GB/T19250-2013

1. Excellent tensile strength and high elasticity,well-adapted to the substrate shrinkage and deformation.

2.Easy to apply, and shorten the construction period.

3.It is safe and environment friendly , tasteless , non-toxic.

4.Colorful,and it can be customized as requirement.

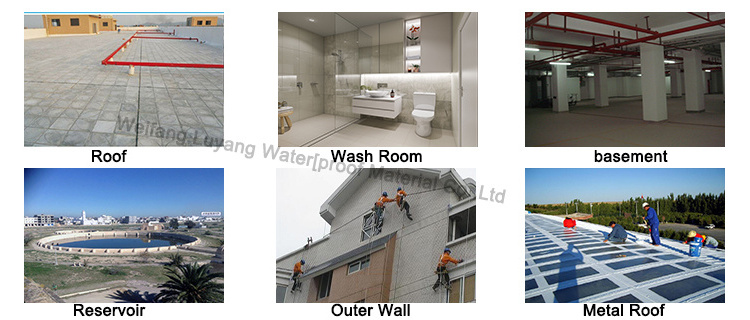

1.Wall surface, basement, tunnel, kitchen, swimming pool, subway, bathroom and so on.

2.Especially used for the place where the shape is complex and irregular.

1.Substrate should be clean , you can brush a little water to keep surface moist ,easy to construction

2.Brush directly after stirring the material evenly .(If the waterproof coating is too dense , you can add water. )

3 3..Brush the coating by 3 or 4 times ,and recommend that the thickness should be not beyond 0.7mm at per coating film.

1.0mm ≤the total thickness ≤2.0mm.

After the first layer is curing ,(interval time : 12h-24h)do the second layer ,And the second should be at right angle to the first layer.

4.If necessary,do the protection layer after the coating is cured.

FAQ

Q: Why choose us ?

A: We are professional manufacturer ,and we can provide the reasonable price and good service.

Q: Do you provide sample?Is it free or extra ?

A: Yes,we can provide free sample for quality inspection.According to our company police , you should assume the freight ,and we will return the freight if you place the order.

Q: Can you tell me your main customers?

A: That's our customers' privacy, we should protect their information.

Q: How about the delivery time ?

A: 7 days after receive the deposit or LC at sight