- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

205

-

Elongation (≥ %):

-

40

-

Specification:

-

OD:2mm~914mm,WT:0.2mm~120mm

-

Grade:

-

TU2,C1020T,C10200,T2,C1100

-

Length:

-

1m,2m,3m,4m,6m,or as required

-

Wall Thickness:

-

0.2mm~120mm

-

Outside Diameter:

-

2mm~914mm

-

Model Number:

-

ASTM B280,JIS H3300,AS/NZS1571

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Copper Tube

-

Keyword:

-

Air Conditioner Tube

-

Material:

-

C11000 C10200 C12200

-

MOQ:

-

2 Tons

-

Payment term:

-

30%TT Advance + 70% Balance

-

Packing:

-

Standard Seaworthy Packing

-

Price term:

-

CIF CFR FOB EXW

-

Hardness:

-

Hard

-

Shape:

-

Round. Square. Rectangular

-

Sample:

-

Sample Freely

Quick Details

-

Type:

-

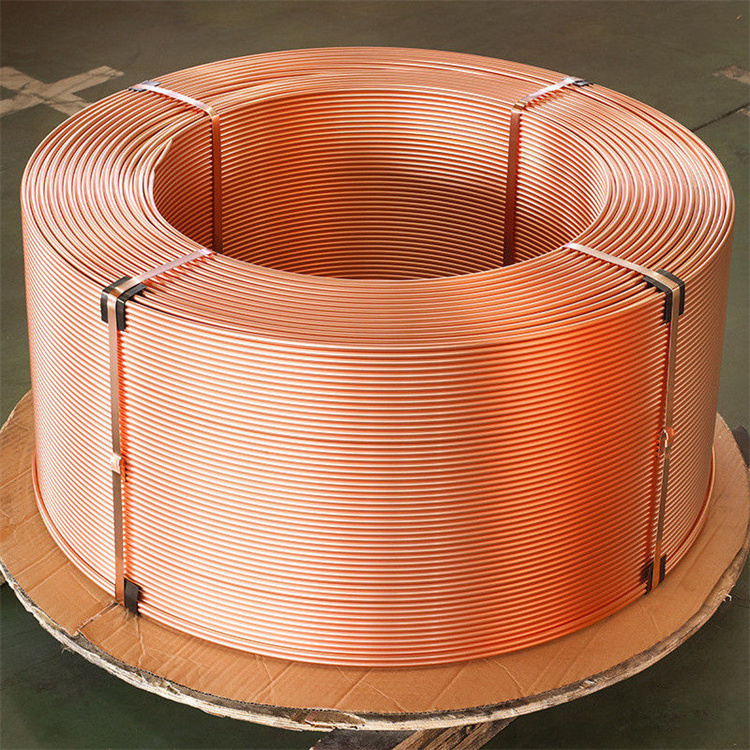

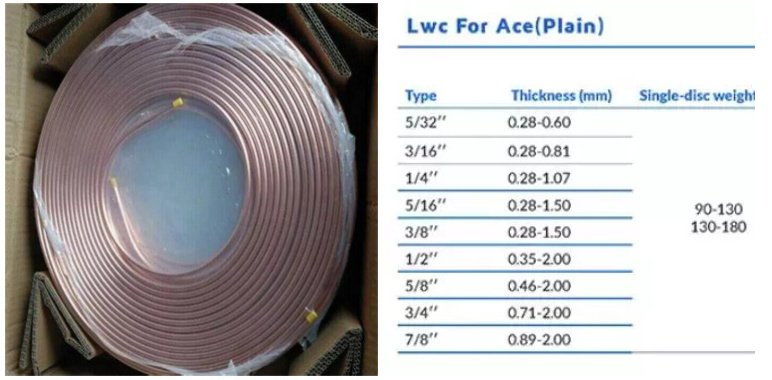

Pancake Coil Copper Pipe

-

Cu (Min):

-

99.99%

-

Alloy Or Not:

-

Non-Alloy

-

Ultimate Strength (≥ MPa):

-

205

-

Elongation (≥ %):

-

40

-

Specification:

-

OD:2mm~914mm,WT:0.2mm~120mm

-

Grade:

-

TU2,C1020T,C10200,T2,C1100

-

Length:

-

1m,2m,3m,4m,6m,or as required

-

Wall Thickness:

-

0.2mm~120mm

-

Outside Diameter:

-

2mm~914mm

-

Model Number:

-

ASTM B280,JIS H3300,AS/NZS1571

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Copper Tube

-

Keyword:

-

Air Conditioner Tube

-

Material:

-

C11000 C10200 C12200

-

MOQ:

-

2 Tons

-

Payment term:

-

30%TT Advance + 70% Balance

-

Packing:

-

Standard Seaworthy Packing

-

Price term:

-

CIF CFR FOB EXW

-

Hardness:

-

Hard

-

Shape:

-

Round. Square. Rectangular

-

Sample:

-

Sample Freely

Please contact me for more product details and the latest prices.

Products Description

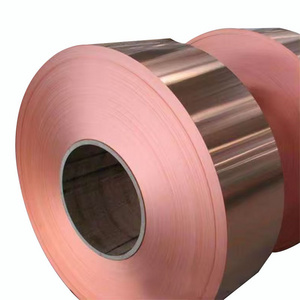

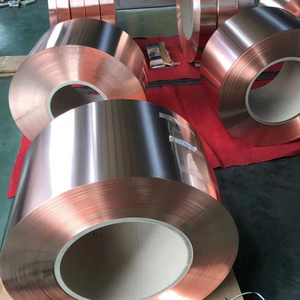

Copper tube is also called red copper tube. One kind of nonferrous metal pipe is pressed and drawn seamless pipe. Copper tube has the characteristics of good conductivity and thermal conductivity. It is the main material for conductive accessories of electronic products and heat dissipation accessories. Copper tubes have strong corrosion resistance and are not easy to be oxidized. They are not easy to react with some liquid substances and are easy to bend.

Specification

|

Copper Pipe

|

|

|

||

|

1

|

Production Standard

|

ASTM, JIS, DIN, GB, ISO

|

||

|

2

|

Material

|

C11000 C10200 C12000 C12200

|

||

|

3

|

Outer Diameter

|

2mm-260mm or as the customer’s request

|

||

|

4

|

Wall Thickness

|

0.2mm-130mm or as the customer’s request

|

||

|

5

|

Length

|

50mm-12000mm

|

||

|

6

|

Hardness

|

O, 1/4 Hard, 1/2Hard, 3/4 Hard, H, EH,

|

||

|

7

|

OEM service

|

Perforated, Cutting special size, Doing flatness, Surface treatment, etc

|

||

|

8

|

payterm

|

EXW, FOB, CIF, CFR, etc

|

||

|

9

|

Payment

|

T/T, L/C, Western Union, Alibaba Trade Assurance, etc

|

||

|

10

|

Delivery Time

|

Within 3 days for our stock size, 7-15 days for our production

|

||

|

11

|

Package

|

Export standard package: bundled wooden box, suit for all kinds of transport,

or According to customer requirements |

||

|

12

|

MOQ

|

No MOQ for stock Size, 100 KG for our production.

|

||

|

13

|

SAMPLE

|

Free and available

|

||

Please contact me for more product details and the latest prices.

Production workshop

The continuous casting and rolling process is defined as the continuous casting and rolling process, in which the liquid copper fired at high temperature is poured into the continuous casting machine and rolled into copper billets (called continuous casting billets). Later, without cooling, it is directly heated in the soaking pit for a certain time and then directly rolled into the hot continuous rolling mill.4

Please contact me for more product details and the latest prices.

Hot Searches