- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Customized Color

-

Roofing:

-

Sandwich Panel. Single Steel Sheet

-

Roof and Wall panel:

-

50mm/75mm Sandwich Panel

-

Door:

-

Sliding Door Or Rolling Up Door

-

Window:

-

Aluminum Alloy Window

-

Material:

-

Q235/Q345 Low Carbon Steel

-

Size:

-

Client Requiremeents

-

Certificate:

-

ISO9001:2008/ISO14001:2004

Quick Details

-

Grade:

-

Q235,Q345

-

Product name:

-

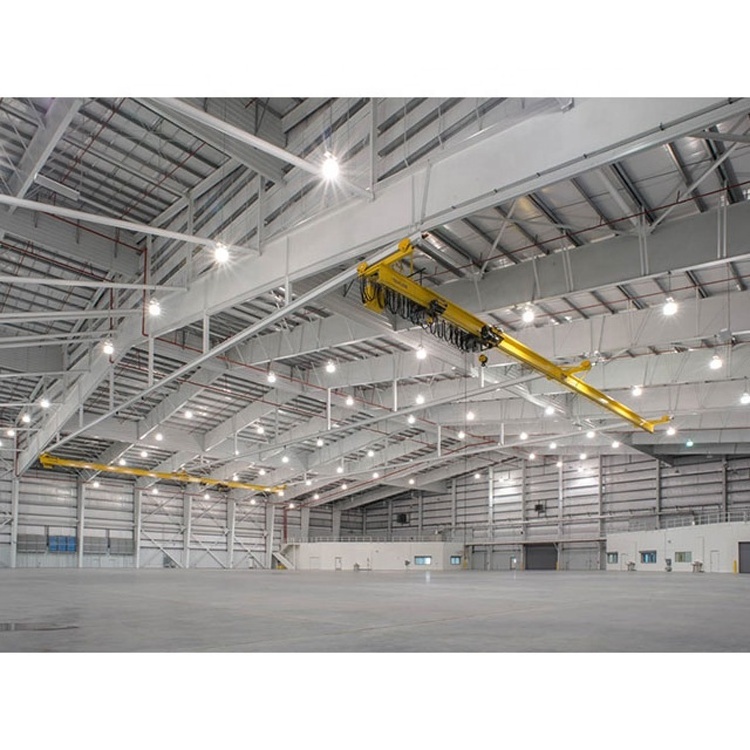

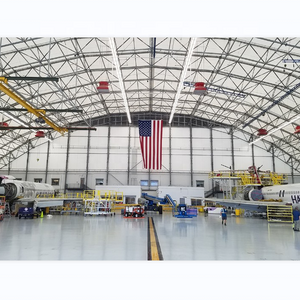

Industrial prefabricated metal roof steel structure Aircraft Hangar

-

Purlin:

-

C.Z Shape Steel

-

Color:

-

Customized Color

-

Roofing:

-

Sandwich Panel. Single Steel Sheet

-

Roof and Wall panel:

-

50mm/75mm Sandwich Panel

-

Door:

-

Sliding Door Or Rolling Up Door

-

Window:

-

Aluminum Alloy Window

-

Material:

-

Q235/Q345 Low Carbon Steel

-

Size:

-

Client Requiremeents

-

Certificate:

-

ISO9001:2008/ISO14001:2004

A steel structure is a metal structure made of structural steel members that are connected to each other to carry loads and provide complete rigidity. Due to the high strength grade of steel, this structure is reliable and requires less raw material than other types of structures such as concrete structures and wood structures.

In modern buildings, steel structures are used in almost every type of structure, including heavy industrial buildings, multi-story buildings, equipment support systems, infrastructure, bridges, towers, airport terminals, and more.

The Metal Building Construction Projects Industrial prefabricated metal roof steel structure Aircraft Hangar Aircraft Hangar specification:

Main Structure

Steel Column: Q345B Welding H section Beam ,Painted : three layer white color anti-rust Alkyd painted

Roof Beam: Q345B Welding H section Beam , Painted : three layer white color anti-rust Alkyd painted

Secondary Structure:

Roof Horizontal Bracing: Q235B Angle Steel , Painted : three layer white color anti-rust Alkyd painted

Wall X Cross Bracing: Q235B Double Angle Steel , Painted : three layer white color anti-rust Alkyd painted

Tie Beam: Q235B Welding Pipe , Painted : three layer white color anti-rust Alkyd painted

Roof Purlin: Galvanized C section steel

Wall Purlin: Galvanized C section steel

Steel Rod: Galvanized Steel Rod

Maintenance Structure

Roof: 0.5mm Single Color sheet

Wall: 0.5mm Single Color sheet

Door: Automatic Steel Sliding Door .

Steel Structure Manufacturing Process:

1. Prepare raw materials : cut steel plate or use H/C section steel and angle steel, round tube, round steel, square tube etc.;

2. Assembly and welding: our welders will follow the drawings to assemble the steel members and weld them together as a entire beam/column/brace and so on; (Our quality inspector will check the steel pieces after finish welding, this is the first quality check)

3. Sand blast : After finish welding and polishing, our sand blast effect can reach 2.5 high grade, very good for resist rust; (Secondary time quality check);

4. Paint : Within 2 hours after sand blast, all the steel members should be paint. Client can choose any color and any brand of paint. (The third time quality check);

5. Inspect the goods by client : After we finish the manufacturing work, we can invite clients to check the goods before packing;

6. Packing and loading : If clients require us to load the goods by close containers, we will pack the steel structure one by one on the steel skid and tie the whole steel package well.

Why choose the BBN?

1. Professional

The company has passed ISO9001 quality management system certification, is a professional production of steel structure houses, container houses, assembly houses, sandwich panels, color steel plates.

2. Quality Management

Quality Control and Stability: Every product from raw material to final inspection undergoes strict quality control and high quality applications ensure that our products achieve perfect performance.

3. Excellent after-sales service

Our customer service team provides you with pre-sales and after-sales services.

4. OEM / ODM available. Custom design; Custom size; Custom brand packaging.