- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Aceretech

-

Application:

-

Plastic Squeezer

-

Production Capacity (kg/h):

-

300 - 800

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

Customized

-

Weight (T):

-

0.6

-

Keywords:

-

Plastic Dewatering And Drying

-

Final product:

-

Dry Plastic Flakes

-

Function:

-

Plastic Dryer

-

Type:

-

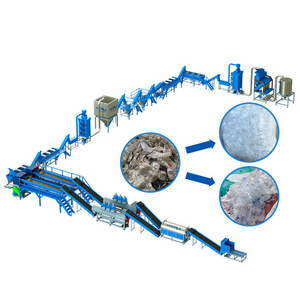

Plastic Recycling Production Line

-

Capacity:

-

300-500kg/h,500-800kg/h

-

Usage:

-

Plstaic Washing Line

-

Machine type:

-

Squeezing

-

Used for:

-

Make Plastic Pellets

-

Product name:

-

ASD Series Plastic Squeezer

Quick Details

-

Machine Type:

-

PP PE Film Washing Line

-

Max.Production Capacity (kg/h):

-

800

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Aceretech

-

Application:

-

Plastic Squeezer

-

Production Capacity (kg/h):

-

300 - 800

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

Customized

-

Weight (T):

-

0.6

-

Keywords:

-

Plastic Dewatering And Drying

-

Final product:

-

Dry Plastic Flakes

-

Function:

-

Plastic Dryer

-

Type:

-

Plastic Recycling Production Line

-

Capacity:

-

300-500kg/h,500-800kg/h

-

Usage:

-

Plstaic Washing Line

-

Machine type:

-

Squeezing

-

Used for:

-

Make Plastic Pellets

-

Product name:

-

ASD Series Plastic Squeezer

3D VR Show Room

Product Description

The new ASD plastic squeezer dryer consists of of main motor, gear box, barrel &screw, die head, pelletizing device and main control cabinet.

The specially designed planetary gearbox and the independently developed thrust bearing seat give the screw a strong thrust and reduce energy consumption. The independently developed thrust bearing seat can bear the axial thrust generated by the equipment

during operation, protect the equipment and extend its service life.

Material fed into barrel&screw through the hopper, then motor driven screw forward, material pass through the high-strength die,then to the pelletizing device and be made into semi-plasticized granules finally, which can be directly secondary granulation or sale.

The new ASD plastic squeezer can control material final moisture within 5-7% effectively and capacity range from 300-800 kg/h.

The specially designed planetary gearbox and the independently developed thrust bearing seat give the screw a strong thrust and reduce energy consumption. The independently developed thrust bearing seat can bear the axial thrust generated by the equipment

during operation, protect the equipment and extend its service life.

Material fed into barrel&screw through the hopper, then motor driven screw forward, material pass through the high-strength die,then to the pelletizing device and be made into semi-plasticized granules finally, which can be directly secondary granulation or sale.

The new ASD plastic squeezer can control material final moisture within 5-7% effectively and capacity range from 300-800 kg/h.

Advantages

- Strong thrust, low power consumption and high performance

- More stable operation and long equipment life

- Low noise and less space required

- Achieved moisture of material under 5-7%

- Cut frequency control, uniform and stable.

- PLC automatic control, simpler operation and more convenient maintenance.

- Semiplastified granules can be used for pelletizing or sold directl.

- More stable operation and long equipment life

- Low noise and less space required

- Achieved moisture of material under 5-7%

- Cut frequency control, uniform and stable.

- PLC automatic control, simpler operation and more convenient maintenance.

- Semiplastified granules can be used for pelletizing or sold directl.

Suitable Products

Product Paramenters

|

SPECIFICATIONS

|

|

|

||

|

Model

|

ASD300

|

ASD320

|

||

|

Main Motor Power

|

90kw

|

132kw

|

||

|

Granulating Motor Power

|

4kw

|

5.5kw

|

||

|

Squeezing Screw Diameter

|

300mm

|

320mm

|

||

|

Equipment Weight

|

~4500KG

|

~6000KG

|

||

|

Capacity

|

300-500kg/h

|

400-550kg/h

|

||

|

Rotating speed

|

65rpm

|

65rpm

|

||

|

Speed of cutting

|

400rpm

|

400rpm

|

||

|

Diameter of final granule

|

≥12mm

|

≥12mm

|

||

|

Fan power

|

5.5kw

|

5.5kw

|

||

|

Volume of Silo

|

0.7CBM

|

0.7CBM

|

||

Product Images

Company Video

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory.

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Hot Searches