- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

250 mm, 210 mm /Customized

-

Brand Name:

-

Aoxuanzg

-

Power (kW):

-

11 kW, 7.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

Anhui

-

Shearing Angle:

-

30'-1°30'

-

Backgauge Travel (mm):

-

20 - 800 mm/ Customized

-

Voltage:

-

220V/380V/Customized

-

Function:

-

Shear Steel Plate/Customized

-

Control system:

-

Customized

-

Color:

-

Customer Selected/ Customized

-

Oil Tank:

-

340L/ Customized

Quick Details

-

Max. Cutting Width (mm):

-

4000

-

Max. Cutting Thickness (mm):

-

40 mm

-

Blade Length (mm):

-

200 mm, 4000 mm/ Customized

-

Throat Depth (mm):

-

250 mm, 210 mm /Customized

-

Brand Name:

-

Aoxuanzg

-

Power (kW):

-

11 kW, 7.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

Anhui

-

Shearing Angle:

-

30'-1°30'

-

Backgauge Travel (mm):

-

20 - 800 mm/ Customized

-

Voltage:

-

220V/380V/Customized

-

Function:

-

Shear Steel Plate/Customized

-

Control system:

-

Customized

-

Color:

-

Customer Selected/ Customized

-

Oil Tank:

-

340L/ Customized

Product Description

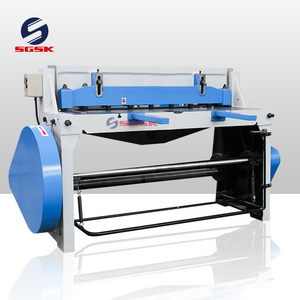

Hot Sale Q11 1.2*250mm Sheet Metal Electric Cutting Machine Electric Shears Mechanical Plate Shearing Machine

Machine Application:

Sheet metal folding machines can be used to shape metal sheets into boxes and pans in various sizes. Also used for ventilation,cases,trays,kitchen,furniture. Consumers can choose the machine according the material thickness ,processing width of the metal sheets.there is light type,heavy type,traditional type(American type or European type),Each type can provide different width to be selected.we can do any model,non-standard products according to customer's special requirement.

Main Features:

1-Special numeric-control system is fitted with mainframe of the bending machine.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well procedures and parameters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

1-Special numeric-control system is fitted with mainframe of the bending machine.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well procedures and parameters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

Product Paramenters

Certifications

Packing & Delivery

Packing Detail:

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

Hot Searches