Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 1220mm

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

7000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

Chile roof metal tile making machinery

-

Control system:

-

Delta

-

Thickness:

-

0.3-0.8 mm

-

Shaft material:

-

75 mm

-

Roller stations:

-

9+15 roller stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Material of rollers:

-

Gcr12 Steel

-

Decoiler:

-

Manual or hydraulic decoiler

-

Control box language:

-

Add Customer Request Language

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20 m/min

-

Rolling thinckness:

-

0.3-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

7000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

Chile roof metal tile making machinery

-

Control system:

-

Delta

-

Thickness:

-

0.3-0.8 mm

-

Shaft material:

-

75 mm

-

Roller stations:

-

9+15 roller stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Material of rollers:

-

Gcr12 Steel

-

Decoiler:

-

Manual or hydraulic decoiler

-

Control box language:

-

Add Customer Request Language

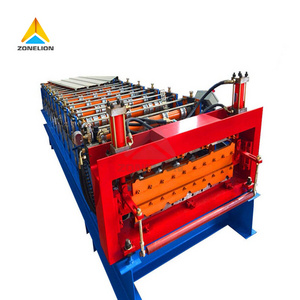

Chile South America double layer trapezoid corrugated roofing sheet making machine tile making machinery

Chile market popular for 5V profile roof sheet, corrugated roof sheet and glazed tile. We can help you purchase roof sheet machine and metal coil, loading together in one container to save freight. About shipping issue and custom clearance. If you want to purchase other goods in China, we also can help you.

If you interested in this machine, please contact me soon, the customer from Alibaba we will have big discount!

The below video is two Chile customers visit our factory, you can check their appraise and feeling to our factory and machine!

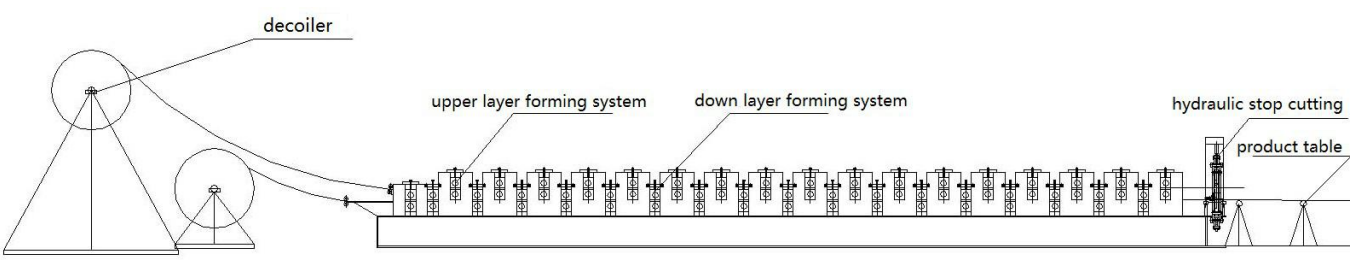

Processing Flow

Uncoiling → Feeding material into machine →Roll forming → Hydraulic cutting →Products receiving

table

table

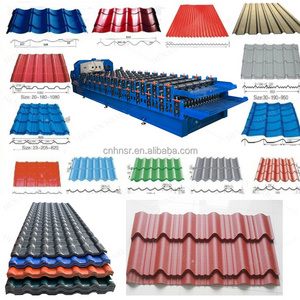

Profile drawing for reference:

In Chile, mainly popular for 5V profile and corrugated roof sheet. Use 1000 mm width coil.

|

Chile double layer roofing sheet machine

|

|

|

|

Raw Material

|

PPGI,PPGL

|

|

|

Raw material

|

Material Thickness: 31-21 Gauge (0.3-0.8 Mm)

|

|

|

Machine Frame

|

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate.

|

|

|

Material Of Rollers

|

High Grade 45# Forged Steel

|

|

|

Material Of Rollers

|

Chromed Treatment (Chrome Thickness:0.05 Mm), Make The Rollers Surface More Smoothly, Improve The Hardness And Prevent Abrasion,Anti Corrosion Increase Of Service Life

|

|

|

Forming Stations

|

Roller Stations : 9+15 Rows

|

|

|

|

Rolling Type: Separate Rolling Design Concept, It Can Release Internal Stress From The Sheets, Then The Sheet Will Be In Good Shape And High Precision.

|

|

|

Diameter Of Shafts

|

Φ75 mm Solid

|

|

|

Material Of Shafts

|

High Grade 45#,With Heat Treatment

|

|

|

Forming Speed

|

20 M/Min

|

|

|

Voltage

|

380v/50hz/3p (As Requested)

|

|

|

Transmission Way

|

By 1 Inch Chain (Double Chains)

|

|

|

Main Motor

|

5.5 kw

|

|

|

Cutting Blade Material

|

Gcr12 quenched treatment

|

|

|

Cutting Type

|

hydraulic post cutting

|

|

|

Driving Method

|

By pillar type Cylinder

|

|

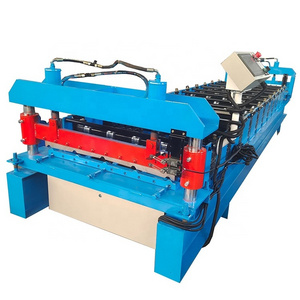

5T Manual Decolier For Free

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rubber rollers can make the steel coil go into the machine smoothly.

4. Pre-cutter can help cut off the material in advance if you want to change coil, save much material.

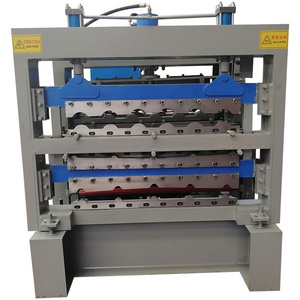

The machine basic frame

Our machine use very thick material to manufacturing the machine basic frame, ensure very stable when it running.

The machine especially add diagonal bracing to make sure stability.

Hydraulic Cutting Device

We use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

Hydraulic station

● Hydraulic station motor: 4 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

CE(

NO.OP180719.CZIDC95

)

ISO 9001(No:ZL92090220234630)

Hot Searches