- Product Details

- {{item.text}}

Quick Details

-

Alumina percentage:

-

high purity alumina ceramic

-

Advantage:

-

Engineering Solutions

-

Supplier:

-

Original Factory

-

Shape:

-

Customization

-

Density:

-

3.9g/cm3

-

Max Use Temperature:

-

1800 ℃

-

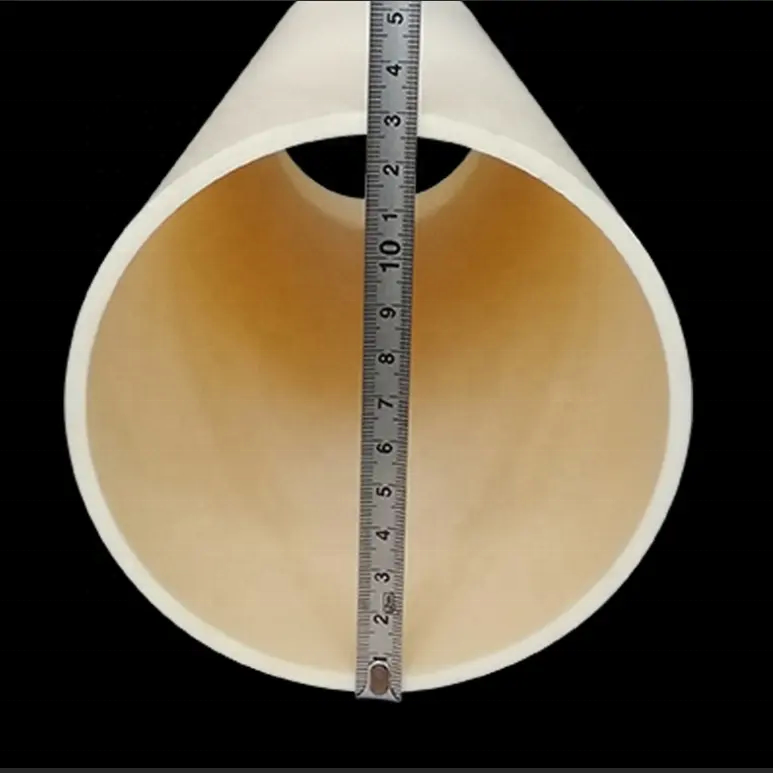

Size:

-

customized size

-

Package:

-

protection safe packing

-

Tolerance:

-

±0.1 mm or custom

-

Usage:

-

electric furnace

Quick Details

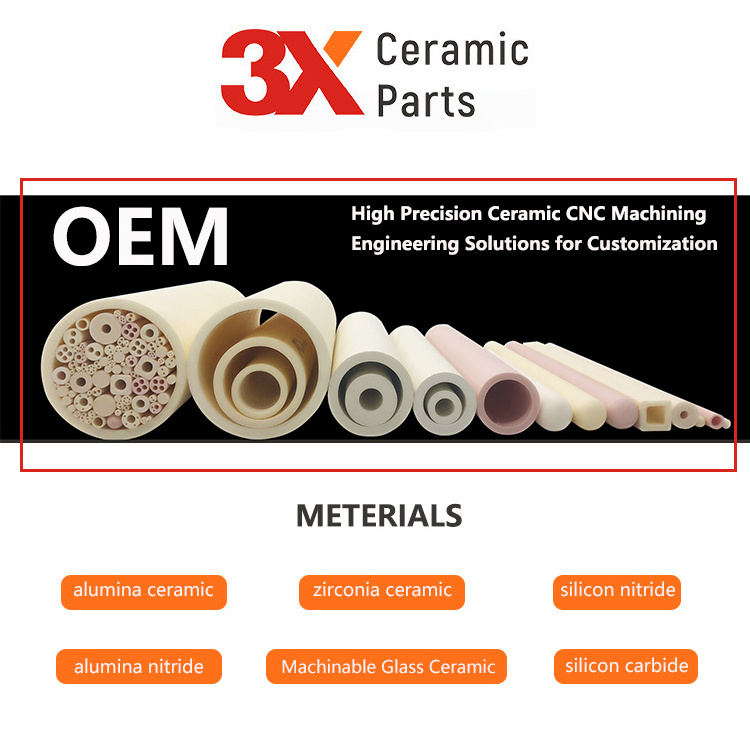

-

Material:

-

High Precision Ceramic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

3X

-

Alumina percentage:

-

high purity alumina ceramic

-

Advantage:

-

Engineering Solutions

-

Supplier:

-

Original Factory

-

Shape:

-

Customization

-

Density:

-

3.9g/cm3

-

Max Use Temperature:

-

1800 ℃

-

Size:

-

customized size

-

Package:

-

protection safe packing

-

Tolerance:

-

±0.1 mm or custom

-

Usage:

-

electric furnace

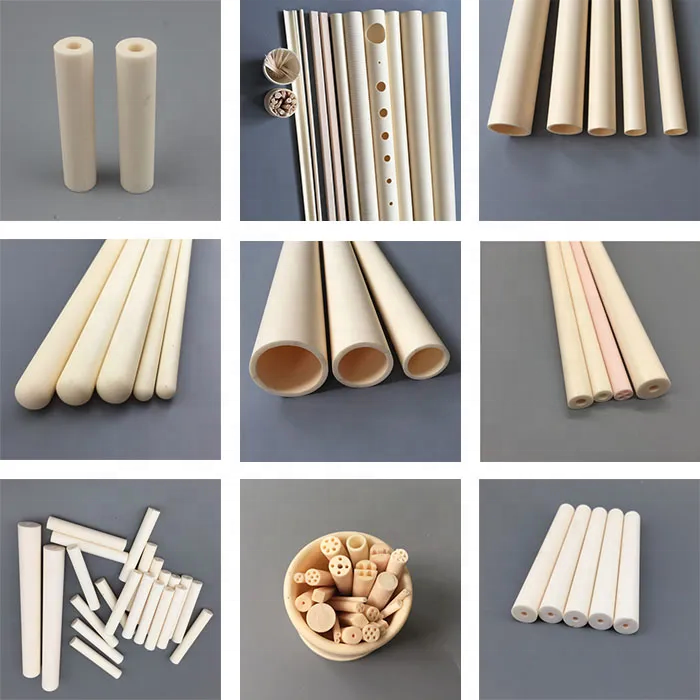

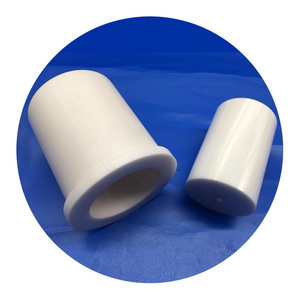

High Temperature Resistance Alumina Ceramic Tube for Electric Heater in the furnace

Benefits of Alumina Ceramic Tubes :

1. Electrical Insulating

2. Thermal shock resistance

3. Wear Resistance

4. High Temperature Resistance

5. High compressive strength

6. Stable Chemical Performance

7. Corrosion Resistance

Features: Alumina ceramic is very stable in air, water vapor, hydrogen, argon, carbon monoxide and vacuum at temperatures below 1700 °C; due to the different purity of alumina when processed into a protective tube, the upper temperature limit can be different.

Alumina protection tube has high air tightness, high temperature resistance, high temperature insulation and corrosion resistance.

Instructions : When in use, the temperature-measuring component of the insulation protection is installed in the protection tube, and then the open end and the even-head are sealed with high-temperature glue. When measuring the temperature, the closed end is inserted into the temperature measurement zone, and the quenching and heat is avoided during use. In order to avoid excessive damage to the protective tube.

Dimension Table for Ceramic furnace tubes:

| Alumina Ceramic Bushing Tube | |||||

| Type & Length | OD* ID ( mm ) | Type & Length | OD* ID ( mm ) | Type & Length | |

| 2*1 | 995AL 1500mm | 10*7 | 95AL / 99AL /995AL 2500mm | 19.05*14.3 | 95AL / 99AL /995AL 2500mm |

| 3*2 | 11.13*7.95 | 20*15 | |||

| 4*2.5 | 12*8 | 22.23 * 15.88 | |||

| 5*3 | 12.7*8.9 | 23.83*17.48 | |||

| 6.35 * 3.96 | 95AL / 99AL /995AL 2500mm | 14*10 | 25.4*19.05 | ||

| 7.95*4.78 | 15*10OD * ID (mm) | 26*20 | |||

| 8*5.5 | 15*11 | 28*22 | |||

| 9.53*6.35 | 16*12 | 30*23 | |||

| 10*6 | 17.48*12.7 | ||||

| Alumina Single Bore Tube | |||||

| OD * ID (mm) | Type & Length | OD* ID ( mm ) | Type & Length | OD* ID ( mm ) | Type & Length |

| 0.7* 0.3 | 99AL/995AL1000mm | 7*4.5 | 95AL / 99AL /995AL 2500mm | 30*25 | 95AL / 99AL /995AL 2500mm |

| 0.8*0.4 | 8*4 | 40*30 | |||

| 0.9*0.4 | 9*6 | 50*40 | |||

| 1*0.5 | 10*4 | 60*50 | |||

| 1.1*0.6 | 10*7 | 70*60 | 95AL / 99AL /995AL 2000mm | ||

| 1.2*0.6 | 12*4 | 80*70 | |||

| 1.3*0.7 | 12*8 | 90*80 | |||

| 1.4*0.8 | 14*4 | 100*90 | |||

| 1.5*0.8 | 95AL / 99AL /995AL 2500mm | 14*10 | 110*100 | ||

| 2*1 | 15*11 | 120*110 | |||

| 3*2 | 16*12 | 150*140 | 95AL / 99AL /995AL 1500mm | ||

| 4*3 | 18*14 | 200*190 | |||

| 5*3.5 | 20*15 | ||||

| 6*4 | 25*19 | ||||

Properties sheet of Alumina Ceramic Tubes :

| Material | Alumina | ||||

| Properties | Units | AL997 | AL995 | AL99 | AL95 |

| % Alumina | ____ | 99.70% | 99.50% | 99% | 95% |

| Colour | —— | ivory | ivory | ivory | ivory & white |

| Permeability | —— | Gas - Tight | Gas - Tight | Gas - Tight | Gas - Tight |

| Density | g/cm3 | 3.94 | 3.9 | 3.8 | 3.75 |

| Straightness | ____ | 1‰ | 1‰ | 1‰ | 1‰ |

| Hardness | Mohs Scale | 9 | 9 | 9 | 8.8 |

| Water Absorption | ____ | 0.2 | 0.2 | 0.2 | 0.2 |

| Flexural Strength ( Typical 20℃) | Mpa | 375 | 370 | 340 | 304 |

| Compressive Strength ( Typical 20℃) | Mpa | 2300 | 2300 | 2210 | 1910 |

| Coefficient of Thermal Expansion ( 25℃ to 800℃) | 10-6/℃ | 7.6 | 7.6 | 7.6 | 7.6 |

| Dielectric Strength (5mm Thickness) | AC-kv/mm | 10 | 10 | 10 | 10 |

| Dielectric Loss 25℃ @1MHZ | ____ | <0.0001 | <0.0001 | 0.0006 | 0.0004 |

| Dielectric Constant | 25℃@1MHz | 9.8 | 9.7 | 9.5 | 9.2 |

| Volume Resistivity (20℃,300℃) | Ω .cm3 | >1014 2*1012 | >1014 2*1012 | >1014 4*1011 | >1014 2*1011 |

| Long - Term Operating Temperature | °C | 1700 | 1650 | 1600 | 1400 |

| Thermal Conductivity ( 25 ℃) | W/m *K | 35 | 35 | 34 | 20 |

More photos of Alumina ceramic tube for electric heaters in the furnace :