1) Precision hydraulic synchronous template adjusting system.

2) Optimal design of high-strength, precision clamping unit.

3) Large screen, high precision machine computer system.

4) Optimized electric system.

5) Balanced type of double whole transfer oil cylinder.

6) Large torque oil motor.

7) High abrasion-resistant alloy sliding block.

8) The integrate type of detachable oil tank, magnetic filter and bypass strainer.

9) Reasonable and high efficient lubrication system.

10) Modularized energy conservation, high response oil-way system.

- Product Details

- {{item.text}}

Quick Details

-

Mold Height(mm):

-

280 - 680 mm

-

Ejector Stroke(mm):

-

180 mm

-

Ejector Force(kN):

-

110 kN

-

Theoretical Shot Volume(cm³):

-

1307 cm³

-

Injection Rate (g/s):

-

301 g/s

-

Injection Weight (g):

-

1190 g

-

Screw Speed (rpm):

-

1 - 140 rpm

-

Screw diameter (mm):

-

70 mm

-

Screw L/D Ratio:

-

21.6

-

Distance between Tie Bars:

-

680*680

-

Weight (KG):

-

13000

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

660 mm

-

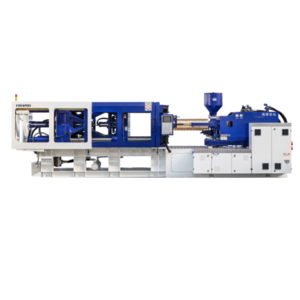

Model Number:

-

OST-3600

-

Brand Name:

-

OSTAR

-

Power (kW):

-

29 kW

-

Product name:

-

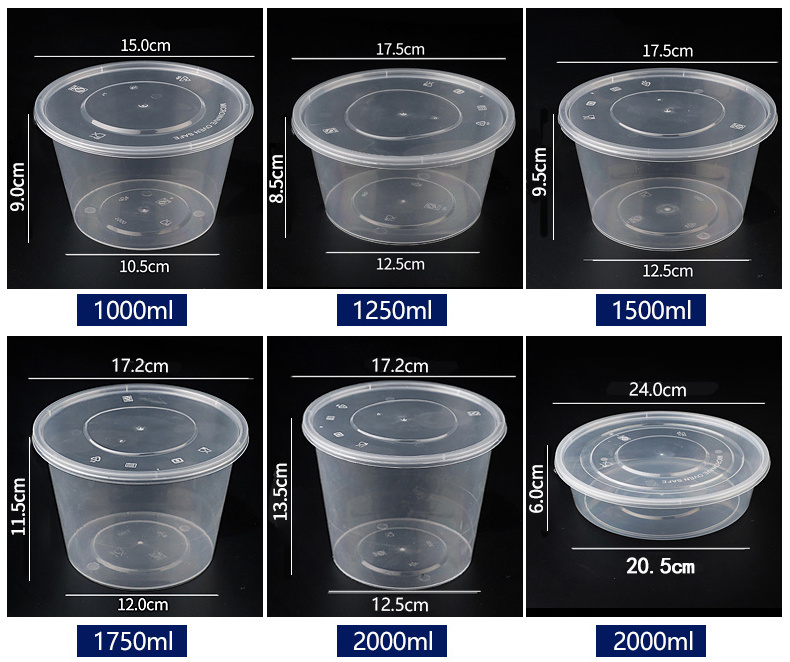

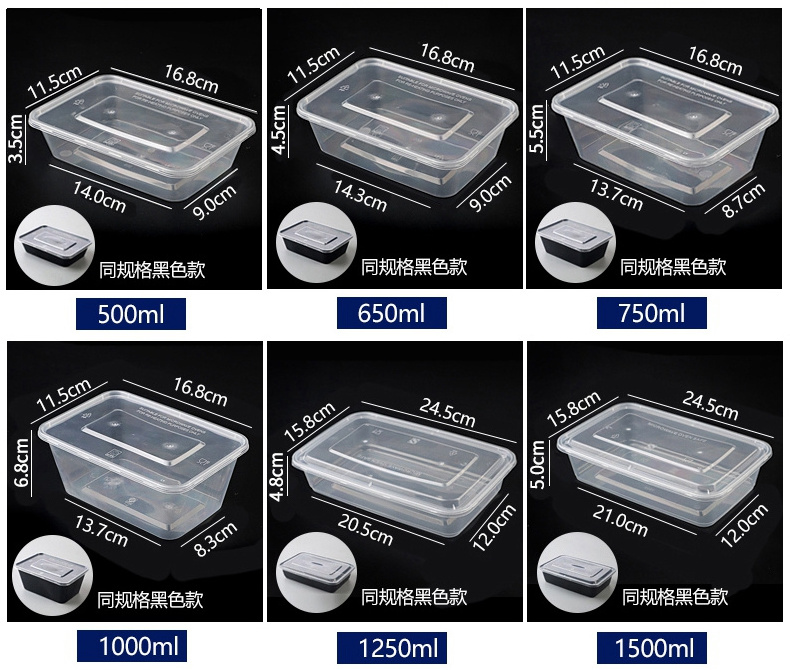

disposable container injection molding machine

-

Function:

-

thin wall food container machine

-

Keyword:

-

Plastic injection Moulding Machine

-

cycle time:

-

4-5s

-

Injection pressure:

-

16Mpa

-

Color:

-

Customrized

-

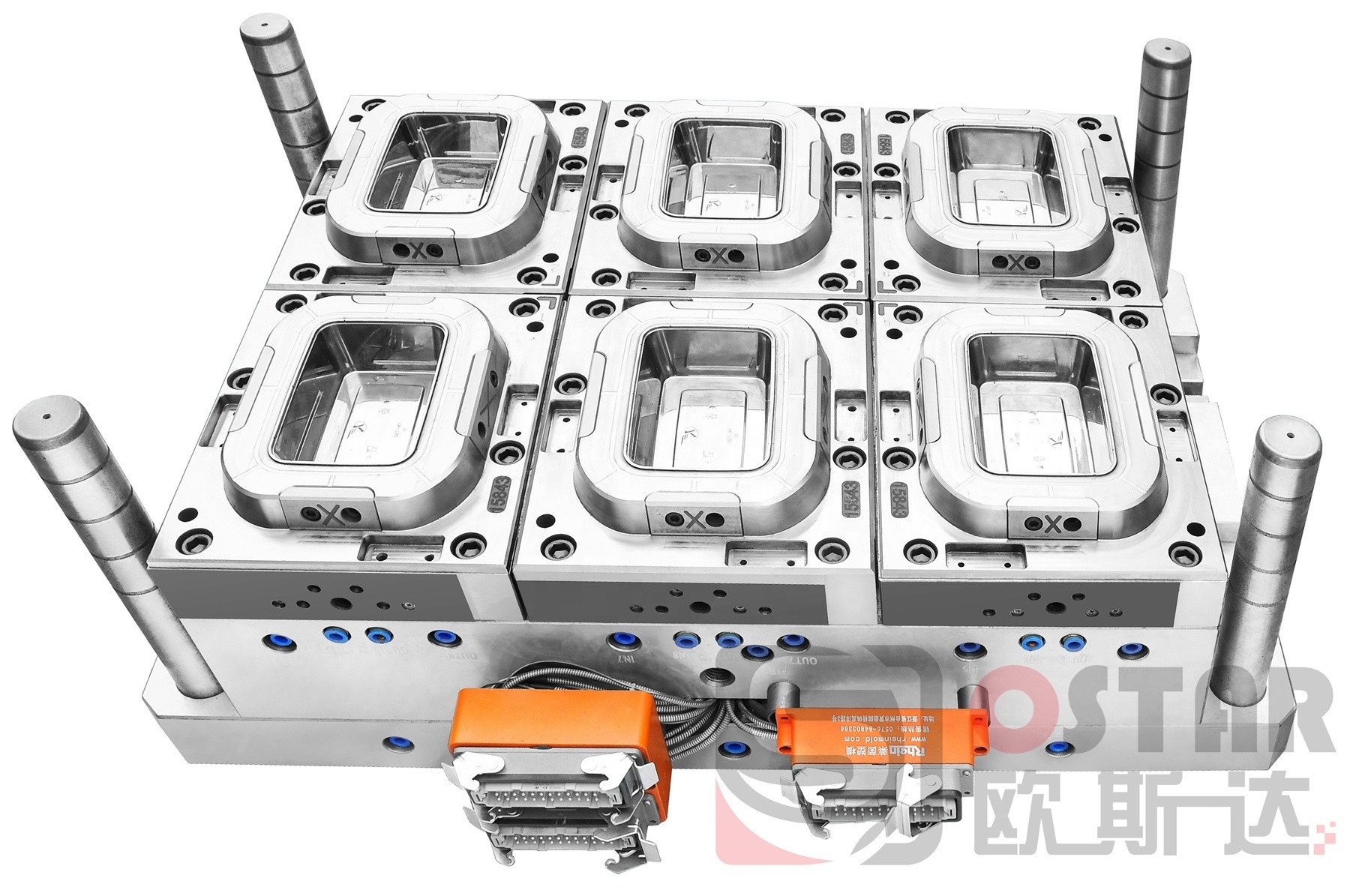

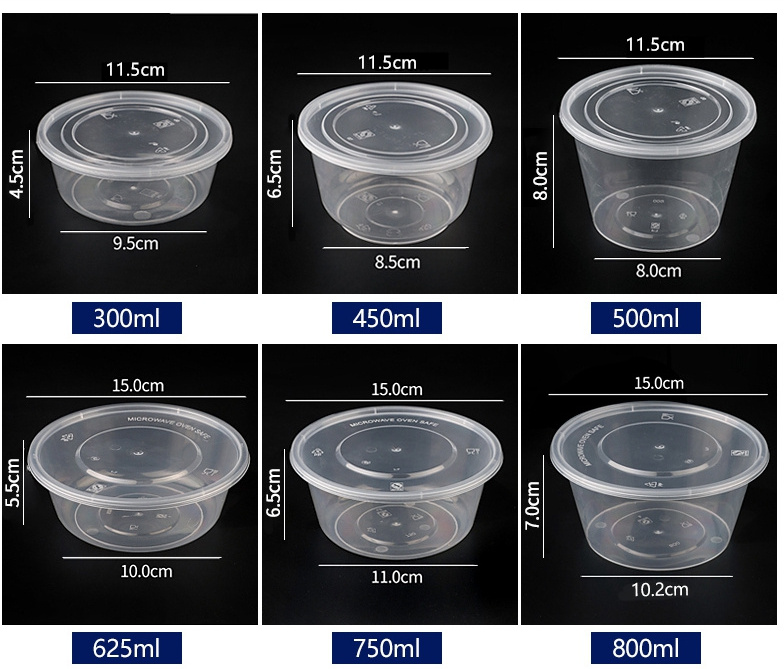

container cavity:

-

multi cavity 2-8cavities

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Engery saving:

-

yes

-

Certification:

-

CE TUV ISO

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

680mm

-

Distance between Tie Bars(Height)(mm):

-

680mm

-

Plasticizing Capacity(g/s):

-

39.8

-

Mold Height(mm):

-

280 - 680 mm

-

Ejector Stroke(mm):

-

180 mm

-

Ejector Force(kN):

-

110 kN

-

Theoretical Shot Volume(cm³):

-

1307 cm³

-

Injection Rate (g/s):

-

301 g/s

-

Injection Weight (g):

-

1190 g

-

Screw Speed (rpm):

-

1 - 140 rpm

-

Screw diameter (mm):

-

70 mm

-

Screw L/D Ratio:

-

21.6

-

Distance between Tie Bars:

-

680*680

-

Weight (KG):

-

13000

-

Place of Origin:

-

Zhejiang, China

-

Open Stroke(mm):

-

660 mm

-

Model Number:

-

OST-3600

-

Brand Name:

-

OSTAR

-

Power (kW):

-

29 kW

-

Product name:

-

disposable container injection molding machine

-

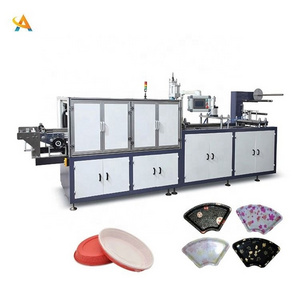

Function:

-

thin wall food container machine

-

Keyword:

-

Plastic injection Moulding Machine

-

cycle time:

-

4-5s

-

Injection pressure:

-

16Mpa

-

Color:

-

Customrized

-

container cavity:

-

multi cavity 2-8cavities

-

Voltage:

-

380V/ 50Hz 3P+N+E (alterable)

-

Engery saving:

-

yes

-

Certification:

-

CE TUV ISO

Machine Introduction

Plastic Injection molding machine 360T

Injection Unit

Large Torque hydraulic motor, for high efficiency raw material plasticizing

Clamping Unit

adopt finite element design with higher strength and more precise operation

Controller Unit

Professional injection molding machine controller, high precision, high respond, high

stabilization.

Electrical Unit

Optimal electrical parts, imported international brands, stable control, long service life.

Hydraulic Unit

Highly response oil way system, impove the machine speed and also save energy comsumption.

Machine Paramenters

|

MACHINE MODEL

|

UNIT

|

OST-3600

|

|

|

||||

|

INJECTION DEVICE

|

|

|

|

|

||||

|

SCREW DIAMETER

|

MM

|

65

|

70

|

72

|

||||

|

SCREW DOAMETER RATIO

|

L/D

|

23.3

|

21.6

|

21

|

||||

|

THEORETICAL SHOT VOLUME

|

CM3

|

1127

|

1307

|

1383

|

||||

|

INJECTION WEIGHT ( PS)

|

G

|

1026

|

1190

|

1259

|

||||

|

INJECTION RATE ( PS)

|

G/S

|

260

|

301

|

319

|

||||

|

INJECTION PRESSURE

|

MPA

|

181

|

156

|

148

|

||||

|

PLASTICIZING CAPACITY( PS)

|

G/S

|

35.3

|

39.8

|

45

|

||||

|

SCREW SPEED

|

RPM

|

140

|

|

|

||||

|

CLAMPING UNIT

|

|

|

|

|

||||

|

CLAMPING FORCE

|

KN

|

3600

|

|

|

||||

|

TOGGLE STROKE

|

MM

|

660

|

|

|

||||

|

SPACE BETWEEN TIE-BARS

|

MM

|

680X680

|

|

|

||||

|

MIN-MAX MOULD THICKNESS

|

MM

|

280-680

|

|

|

||||

|

EJETION STROKE

|

MM

|

180

|

|

|

||||

|

EJECTING FORCE

|

KN

|

110

|

|

|

||||

|

EJECTOR NUMBER

|

PC

|

13

|

|

|

||||

|

OTHERS

|

|

|

|

|

||||

|

MAXIMUM SYSTEM PRESSURE

|

MPA

|

16

|

|

|

||||

|

OIL PUMP MOTOR POWER

|

KW

|

30( 35.6)

|

|

|

||||

|

HEATER POWER

|

KW

|

29

|

|

|

||||

|

OIL TANK CAPACITY

|

KG

|

520

|

|

|

||||

|

OVERALL DIMENSION (ROUGH )

|

MM

|

7200X1860

X2350

|

|

|

||||

|

MACHINE WEIGHT ( ROUGH )

|

TON

|

13

|

|

|

||||

Company Introduction

About Us

Our company was founded in 1995, more than 15 years experience on plastic injection molding machine manufacturing&exporting. we

have own machine compoent processing workshop, R&D team, experienced machine assembly workers. machine inspection and

after-service department. we supply machine from 30tons to 2000tons, for different customer choose. We are not only win by

machine price, but also win by machine quality and service. we sure our machine would make you happy and benefit if you choose us.

have own machine compoent processing workshop, R&D team, experienced machine assembly workers. machine inspection and

after-service department. we supply machine from 30tons to 2000tons, for different customer choose. We are not only win by

machine price, but also win by machine quality and service. we sure our machine would make you happy and benefit if you choose us.

Why Choose Us

We have own machine design department, for new machine design, and each machine component are process in our own workshop, to make

sure strictly quality control. inspection team would check every machine before shipment, keep every machine in good condition

sure strictly quality control. inspection team would check every machine before shipment, keep every machine in good condition

Shipment

We are experience on machine loading and ocean shippment. we use strong belt to fix the machine, make sure no any movement during long time shippment.

Machines good protected with anti-rust.

Customer Photos

We provide ovesea services, after machine arrive your factory, our engineer would come to you, to help you install and star the machines, training your workers, to start everything.

Recommend Products

FAQ

Q1: Are you a trading company or a manufacturer?

A1: We are a manufacturer, we supply the factory price with good quality, welcome to visit !

Q2:How about quality control in your factory?

A2: We have a pre-shipment inspection team, every machine need at least automatic running over 72 hours before shipment.

Q3: Is there complete machine include mould and other auxiliary equipment ?

A3: Yes ,what we are provide is the complete A-Z solution line.

Q4: Could you send your engineer to my country, to start the machine?

A4: Surely, we have experience technical engineer for oversea service, they would help you install machine, training your workers.

Q5: Can you help us with the shipment of this machine ?

A5: We have our special shipment company which already cooperate

for long time, we will give you the best price, fast delivery.

A1: We are a manufacturer, we supply the factory price with good quality, welcome to visit !

Q2:How about quality control in your factory?

A2: We have a pre-shipment inspection team, every machine need at least automatic running over 72 hours before shipment.

Q3: Is there complete machine include mould and other auxiliary equipment ?

A3: Yes ,what we are provide is the complete A-Z solution line.

Q4: Could you send your engineer to my country, to start the machine?

A4: Surely, we have experience technical engineer for oversea service, they would help you install machine, training your workers.

Q5: Can you help us with the shipment of this machine ?

A5: We have our special shipment company which already cooperate

for long time, we will give you the best price, fast delivery.

Hot Searches