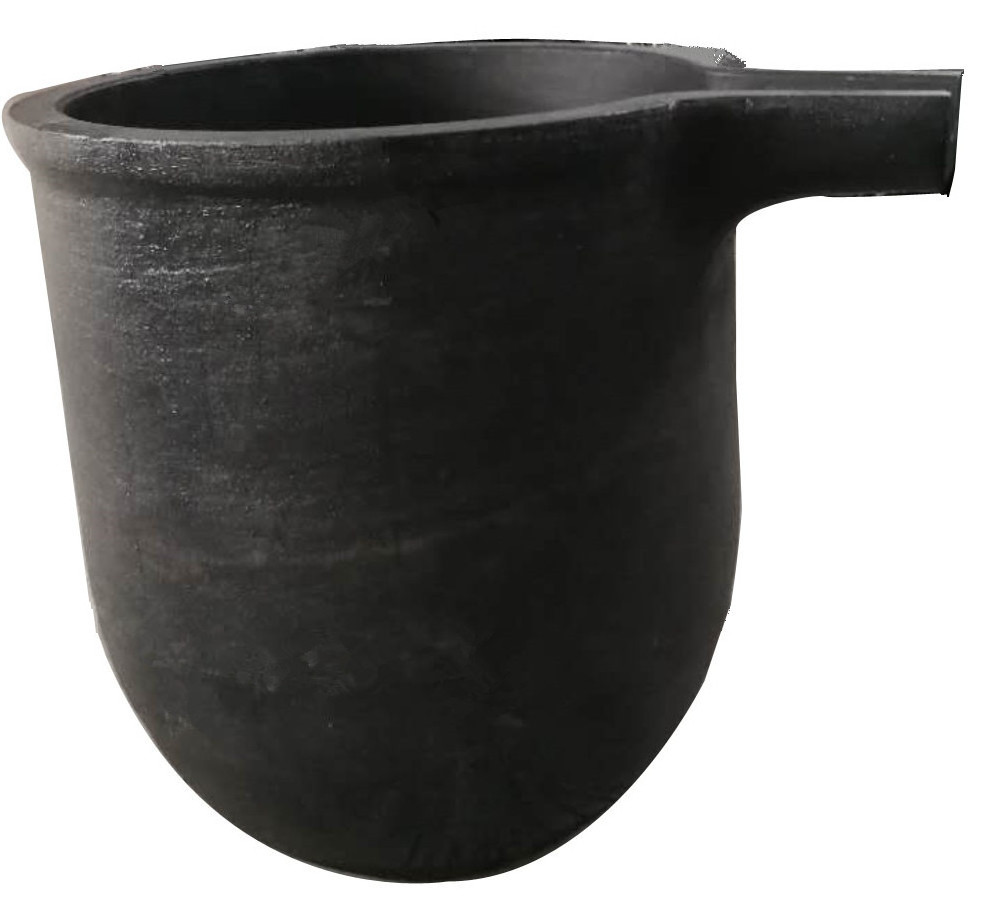

JSH Graphite crucible is divided into four categories: high purity fine particle graphite crucible, medium particle graphite crucible, silicon carbide graphite crucible and other coated graphite crucible(graphite crucible for vacuum coating of gasification aluminum)

Graphite crucible has good thermal conductivity and high temperature resistance, the use of high temperature, the thermal expansion coefficient is small, the rapid heat, quenching has a certain anti-strain properties. Right acid, alkaline solution, strong corrosion resistance, with excellent chemical stability.

Due to its excellent performance, graphite crucible is widely used in metallurgy, casting, machinery, chemical and other industrial sectors for the smelting of alloy tool steel and the smelting of non-ferrous metals and their alloys, and has good technical and economic effects.

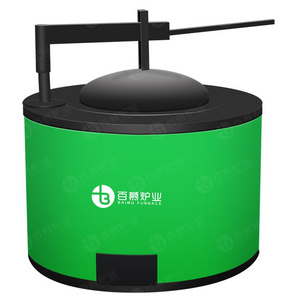

- Product Details

- {{item.text}}

Quick Details

-

Top Diameter:

-

customized

-

Bottom Diameter:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JSH Graphite

-

Model Number:

-

JSH-3

-

Product name:

-

SIC graphite crucible

-

Advantage:

-

High Temperature Resistance

-

Carbon Content:

-

30-40%

-

Bulk Density:

-

1.91-2.1g/cm3

-

Crucible graphite application:

-

Melting Copper and Aluminium

-

Size and Shape:

-

Customizble

-

Working Temperature:

-

Less than 4350℃

-

Raw material:

-

99.9% carbon graphite

-

Port:

-

Shanghai

Quick Details

-

Type:

-

Refractory

-

Application:

-

Melting Metal, Smelting industry

-

Height:

-

customized

-

Top Diameter:

-

customized

-

Bottom Diameter:

-

customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JSH Graphite

-

Model Number:

-

JSH-3

-

Product name:

-

SIC graphite crucible

-

Advantage:

-

High Temperature Resistance

-

Carbon Content:

-

30-40%

-

Bulk Density:

-

1.91-2.1g/cm3

-

Crucible graphite application:

-

Melting Copper and Aluminium

-

Size and Shape:

-

Customizble

-

Working Temperature:

-

Less than 4350℃

-

Raw material:

-

99.9% carbon graphite

-

Port:

-

Shanghai

Product Description

Four categories graphite crucible and Tech Data:

a. High purity fine particle graphite crucible

|

Density g/cm³

|

1.75-1.9

|

|

Resistivity μΩ·m

|

≤18

|

|

Flexural Strength Mpa

|

40-80

|

|

Compressive strength Mpa

|

60-160

|

|

Porosity %

|

≤20

|

|

Elasticity Modulus Gpa

|

6-18

|

|

Thermal expansion coefficient 10-6/ºC

|

1.47-4.25

|

|

Ash content %

|

≤0.5

|

|

Temperature resistance ºC

|

≤4350

|

b. Medium particle graphite crucible

c. Silicon carbide graphite crucible

d. Graphite crucible for vaccum metallizing

Graphite crucible for vacuum coating of gasification aluminum for example. Is mainly suitable for under the condition of vacuum, the metal aluminum gasification and evaporation on the surface of CPP, PET, BOPP film, And forming aluminum composite film.

Graphite crucibles are a large number of consumption parts during the producing process, the quality of graphite crucibles will directly affect the product quality and production cost of aluminum plating film.

JSH graphite has developed a new kind graphite composite materials, used for vacuum coating of gasification aluminum, with outstanding features: greatly improve its oxidation resistance, high bulk density and flexural compressive strength, increased abrasion resistance and hardness, reduce porosity and permeability. The wetting and erosion ability of molten aluminum liquid and gaseous aluminum molecules is weakened to a large extent, and thus the service life of the crucible is prolonged.

JSH graphite has developed a new kind graphite composite materials, used for vacuum coating of gasification aluminum, with outstanding features: greatly improve its oxidation resistance, high bulk density and flexural compressive strength, increased abrasion resistance and hardness, reduce porosity and permeability. The wetting and erosion ability of molten aluminum liquid and gaseous aluminum molecules is weakened to a large extent, and thus the service life of the crucible is prolonged.

Our Advantages

1. High strength. As the temperature rises, the graphite strength increases

2. High temperature resistance

3. Good heat shock resistance

4. Anti-oxidation

5. Strong corrosion resistance to acid and alkali liquid

6. Good conductivity and thermal efficiency.

7. Excellent chemical stability

8. High heat conductivity

9. Mechanical shock resistance

10. Small thermal expansion coefficient

2. High temperature resistance

3. Good heat shock resistance

4. Anti-oxidation

5. Strong corrosion resistance to acid and alkali liquid

6. Good conductivity and thermal efficiency.

7. Excellent chemical stability

8. High heat conductivity

9. Mechanical shock resistance

10. Small thermal expansion coefficient

Application area

Hot Searches