- Product Details

- {{item.text}}

Quick Details

-

Tolerance:

-

±1%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiujin

-

Application:

-

Building Construction

-

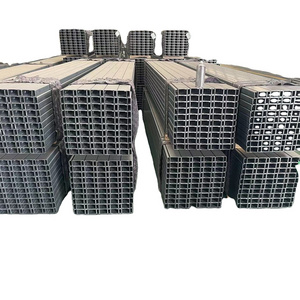

Product name:

-

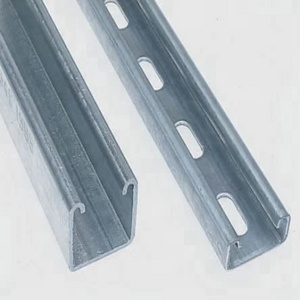

Channel Steel Profile

-

MOQ:

-

1 Ton

-

Type:

-

Carbon Structural Steel

-

Technique:

-

Cold Rolled Hot Rolled

-

Length:

-

Customer's Demand

-

Size:

-

Customer's Requst

-

Sample:

-

Sample Freely

-

Payment:

-

30%TT+70%TT

-

Usage:

-

Commercial Buildings

-

Surface:

-

Hot Dip Galvanied

Quick Details

-

Standard:

-

ASTM/AISI/DIN/JIS

-

Grade:

-

Carbon steel/galvanized steel

-

Shape:

-

C Channel

-

Tolerance:

-

±1%

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jiujin

-

Application:

-

Building Construction

-

Product name:

-

Channel Steel Profile

-

MOQ:

-

1 Ton

-

Type:

-

Carbon Structural Steel

-

Technique:

-

Cold Rolled Hot Rolled

-

Length:

-

Customer's Demand

-

Size:

-

Customer's Requst

-

Sample:

-

Sample Freely

-

Payment:

-

30%TT+70%TT

-

Usage:

-

Commercial Buildings

-

Surface:

-

Hot Dip Galvanied

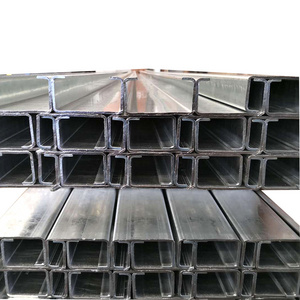

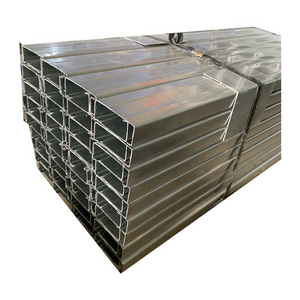

Products Description

U-steel

, also known as

U-shaped steel

or

U-channel

, is a type of structural steel product with a U-shaped cross-section. It is commonly used in construction, engineering, and manufacturing industries due to its versatility, strength, and stability. Below is a brief overview of

U-steel

:

Description:

Applications:

Description:

U-steel

consists of a horizontal base called the "web" and two vertical sides called "flanges." The flanges are

perpendicular to the web, forming the U-shaped cross-section. The dimensions of U-steel can vary, including different sizes of the web height, flange width, and thickness, depending on specific applications.

perpendicular to the web, forming the U-shaped cross-section. The dimensions of U-steel can vary, including different sizes of the web height, flange width, and thickness, depending on specific applications.

Applications:

U-steel is widely used in various industries and applications, including:

1. Construction: U-steel is commonly used as structural elements in building frames, supporting beams, columns, and roof trusses.

2. Manufacturing: It is used in the fabrication of machinery, equipment, and vehicles, providing structural support and

stability.

3. Support Systems: U-steel is often employed in shelving systems, racks, and storage units to organize and store items

efficiently.

4. Infrastructure: U-steel finds applications in bridges, piers, tunnels, and other infrastructure projects as load-bearing

components.

Production Process:

1. Construction: U-steel is commonly used as structural elements in building frames, supporting beams, columns, and roof trusses.

2. Manufacturing: It is used in the fabrication of machinery, equipment, and vehicles, providing structural support and

stability.

3. Support Systems: U-steel is often employed in shelving systems, racks, and storage units to organize and store items

efficiently.

4. Infrastructure: U-steel finds applications in bridges, piers, tunnels, and other infrastructure projects as load-bearing

components.

Production Process:

The production process of U-steel generally involves the following steps:

1. Melting and Casting: The raw materials, including iron ore and scrap steel, are melted in a furnace to produce molten steel.

2. Continuous Casting: The molten steel is poured into a continuous casting machine, where it solidifies into rectangular

billets.

3. Heating and Rolling: The billets are reheated and then passed through a series of rolling mills to gradually shape them into the desired U-shaped profile.

4. Cooling and Cutting: After rolling, the U-steel is cooled and then cut into specific lengths according to customer

requirements.

Material Specifications:

1. Melting and Casting: The raw materials, including iron ore and scrap steel, are melted in a furnace to produce molten steel.

2. Continuous Casting: The molten steel is poured into a continuous casting machine, where it solidifies into rectangular

billets.

3. Heating and Rolling: The billets are reheated and then passed through a series of rolling mills to gradually shape them into the desired U-shaped profile.

4. Cooling and Cutting: After rolling, the U-steel is cooled and then cut into specific lengths according to customer

requirements.

Material Specifications:

U-steel can be manufactured using various materials, including carbon steel (such as Q235B, Q345B),stainless steel, and alloy steel. The choice of material depends on factors such as required strength, corrosion resistance, and cost considerations.

Classification: U-steel can be classified based on different factors such as dimensions, material, and manufacturing standards.

Some common classifications include:

1. Standard U-Steel: This refers to U-steel products that adhere to specific standards, such as GB/T 706-2008 in China or ASTM A36/A36M in the United States.

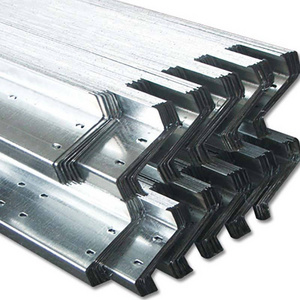

2. Parallel Flange Channel: This type of U-steel has parallel flanges of equal width.

3. Tapered Flange Channel: The flanges of this U-steel shape taper towards the top, reducing the weight and improving

load-bearing capacity.

4. Stainless Steel U-Channel: These U-steel profiles are made from stainless steel, offering enhanced corrosion resistance

Classification: U-steel can be classified based on different factors such as dimensions, material, and manufacturing standards.

Some common classifications include:

1. Standard U-Steel: This refers to U-steel products that adhere to specific standards, such as GB/T 706-2008 in China or ASTM A36/A36M in the United States.

2. Parallel Flange Channel: This type of U-steel has parallel flanges of equal width.

3. Tapered Flange Channel: The flanges of this U-steel shape taper towards the top, reducing the weight and improving

load-bearing capacity.

4. Stainless Steel U-Channel: These U-steel profiles are made from stainless steel, offering enhanced corrosion resistance

|

Material

|

Q195,Q235,Q345,A36,SS400,s235jr

|

|

|

Spezifikation

|

GB standard(10 #-40 #,100*48mm-400*102mm)

JIS standard(50*25mm-250*90mm) |

|

|

Länge

|

6m, 9m,12m, Große menge kann angepasst werden

|

|

|

Größe Toleranz

|

± 1%

|

|

|

Form

|

U Form/C Form

|

|

|

Prozess

|

Warmgewalzte, Kalt Gezogen

|

|

|

Länge

|

Als antrag des kunden

|

|

|

Technologie

|

Heiße rolle, kalt roll, kalt gezogen, ect.

|

|

|

Oberfläche

|

Verzinkt, Pulver Beschichtung, Schwarz Lack

|

|

|

Rand

|

Mühle Rand Schlitz Rand

|

|

|

Zertifizierungen

|

MTC,ISO9001, BV, TÜV

|

|

|

Zahlung

|

T/T,L/C,Western Union,Paypal,Apple Zahlen, Google Zahlen, D/A,D/P,MoneyGram

|

|

|

Preis Begriff

|

Ex-arbeit, FOB, CIF , CFR, etc

|

|

|

Lieferung zeit

|

In der regel 15 arbeitstage, ihre kauf volumen bestimmt unsere lieferung zeit

|

|

|

Probe

|

Kostenloser, Kontaktieren Sie uns zu erfahren sie mehr

|

|

|

Verpackung

|

Industrie standard verpackung oder nach kunden anforderung

|

|

|

|

||

Details Images

Hot Searches