- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 50HZ

-

Dimension(L*W*H):

-

as capacity

-

Weight (KG):

-

1000

-

Power (kW):

-

30

-

Application:

-

Sulphur-coated urea production line

-

Raw material:

-

Nitrogen, phosphorus and UREA

-

Production capacity:

-

1-15 t/h

-

Working method:

-

granulating

-

Granulate size:

-

3-5mm

-

Granulation method:

-

wet type

-

manpower number:

-

7-10 persons

-

Name:

-

Urea Fertilizer Production Plant

-

warranty:

-

5 years

-

Color:

-

Customers' Demand

Quick Details

-

Output (kg/h):

-

3000

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GATE

-

Voltage:

-

380V, 50HZ

-

Dimension(L*W*H):

-

as capacity

-

Weight (KG):

-

1000

-

Power (kW):

-

30

-

Application:

-

Sulphur-coated urea production line

-

Raw material:

-

Nitrogen, phosphorus and UREA

-

Production capacity:

-

1-15 t/h

-

Working method:

-

granulating

-

Granulate size:

-

3-5mm

-

Granulation method:

-

wet type

-

manpower number:

-

7-10 persons

-

Name:

-

Urea Fertilizer Production Plant

-

warranty:

-

5 years

-

Color:

-

Customers' Demand

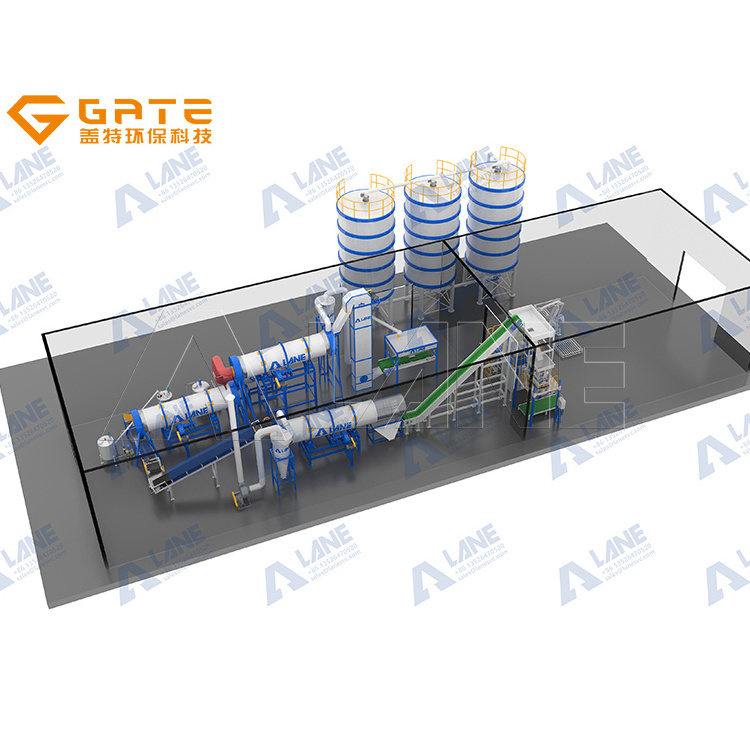

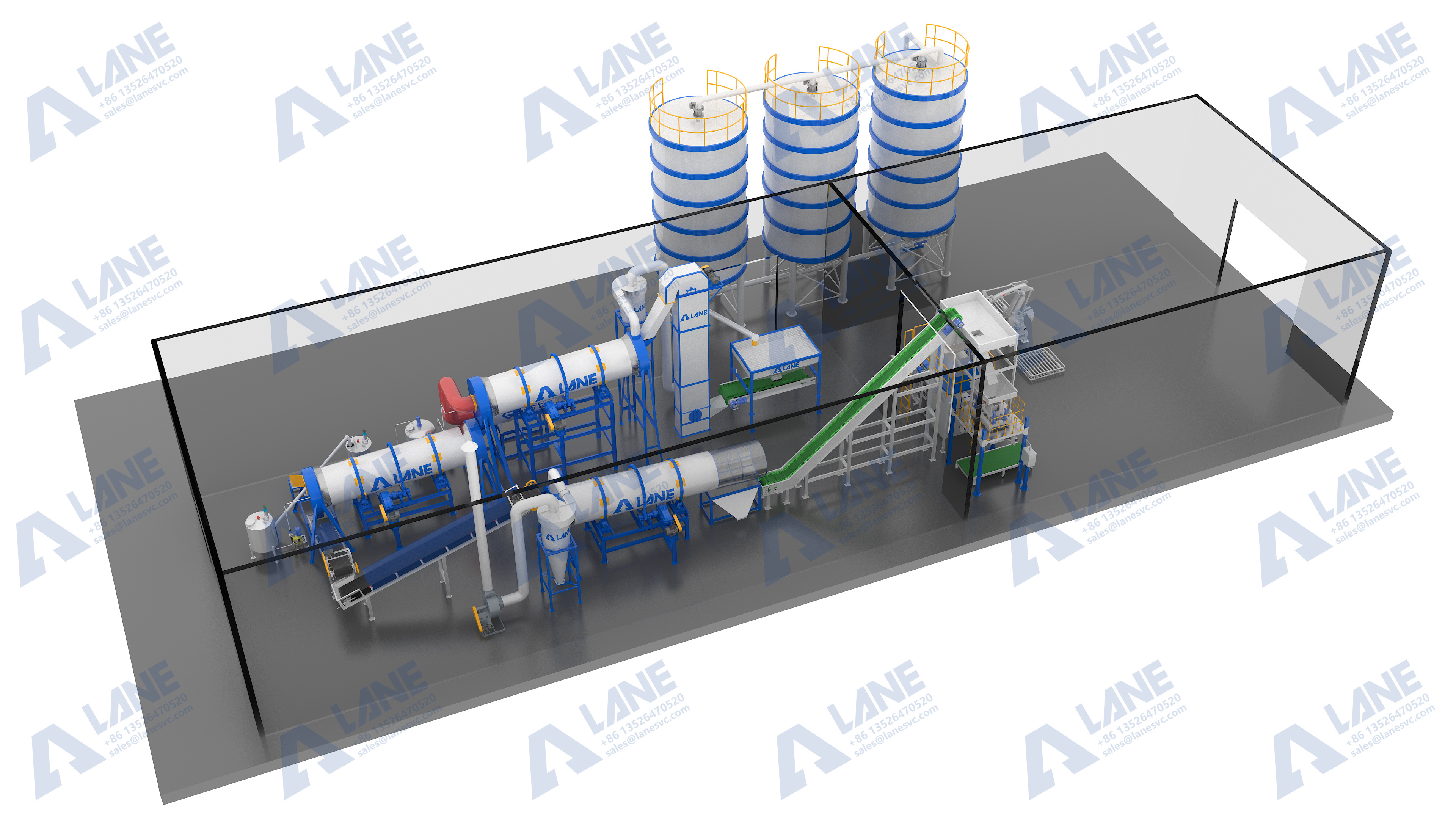

Sulfur coated urea production line

Sulfur coated urea fertilizer is a slow-release fertilizer that wraps a sulfur coating layer on the surface of urea particles to

reduce the solubility and volatility of urea, slowing down the release rate of fertilizer in the soil and allowing crops to

receive appropriate amounts of nutrients at different growth stages. This not only increases crop yield and fertilizer utilization efficiency, but also greatly reduces soil pollution caused by excessive fertilization!

reduce the solubility and volatility of urea, slowing down the release rate of fertilizer in the soil and allowing crops to

receive appropriate amounts of nutrients at different growth stages. This not only increases crop yield and fertilizer utilization efficiency, but also greatly reduces soil pollution caused by excessive fertilization!

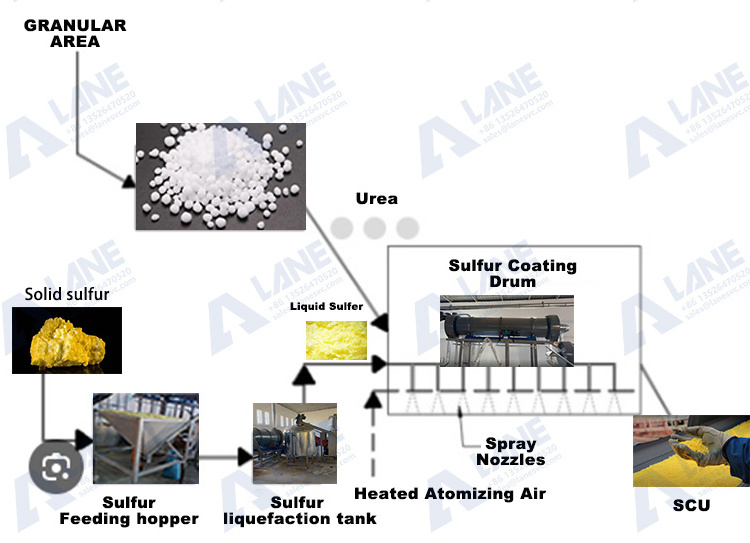

The following is the production process of sulfur coated urea

The sulfur coating method is another commonly used process for producing sulfur coated urea. The specific steps are as follows:

1. Prepare the sulfur layer solution. Add sulfur to the solvent and heat and stir to dissolve the sulfur.

2. Prepare urea particles.

3. Sulfur layer wrapping. Mix urea particles with sulfur layer solution to coat the surface of urea particles with sulfur.

4. Drying treatment. Treat sulfur coated urea particles by drying and other methods to reduce their moisture content to an appropriate level.

Ensuring the dissolution and uniformity of sulfur in the production process of sulfur coated urea is one of the key steps. Here are some possible methods:

1. Choose the appropriate solvent: Sulfur has a high solubility in some solvents, so choosing the appropriate solvent is crucial for the dissolution of sulfur. Common solvents include * * *, * * *, * * *, * *, etc. (For more information, please contact us)

2.Heating and stirring: After adding sulfur to the solvent, heating and stirring can promote the dissolution of sulfur..

3. Grinding dissolution: Grinding can increase the surface area of sulfur particles, making them easier to come into contact with solvents and dissolve.

4. Ultrasonic assistance: By placing the mixture in an ultrasonic bath and utilizing the vibration and resonance effects

of ultrasound, collisions and dispersion between particles can be increased, thereby promoting the dissolution of sulfur

molecules.

of ultrasound, collisions and dispersion between particles can be increased, thereby promoting the dissolution of sulfur

molecules.

5. Temperature control: The solubility of sulfur varies with temperature, usually increasing with increasing

temperature.

temperature.

6. Mixing speed and time: Proper mixing speed and time are crucial to ensure the uniformity of sulfur. If the

stirring speed is too fast, foam may be generated, while if the stirring time is too short, the sulfur particles may not be fully

dissolved and dispersed.

stirring speed is too fast, foam may be generated, while if the stirring time is too short, the sulfur particles may not be fully

dissolved and dispersed.

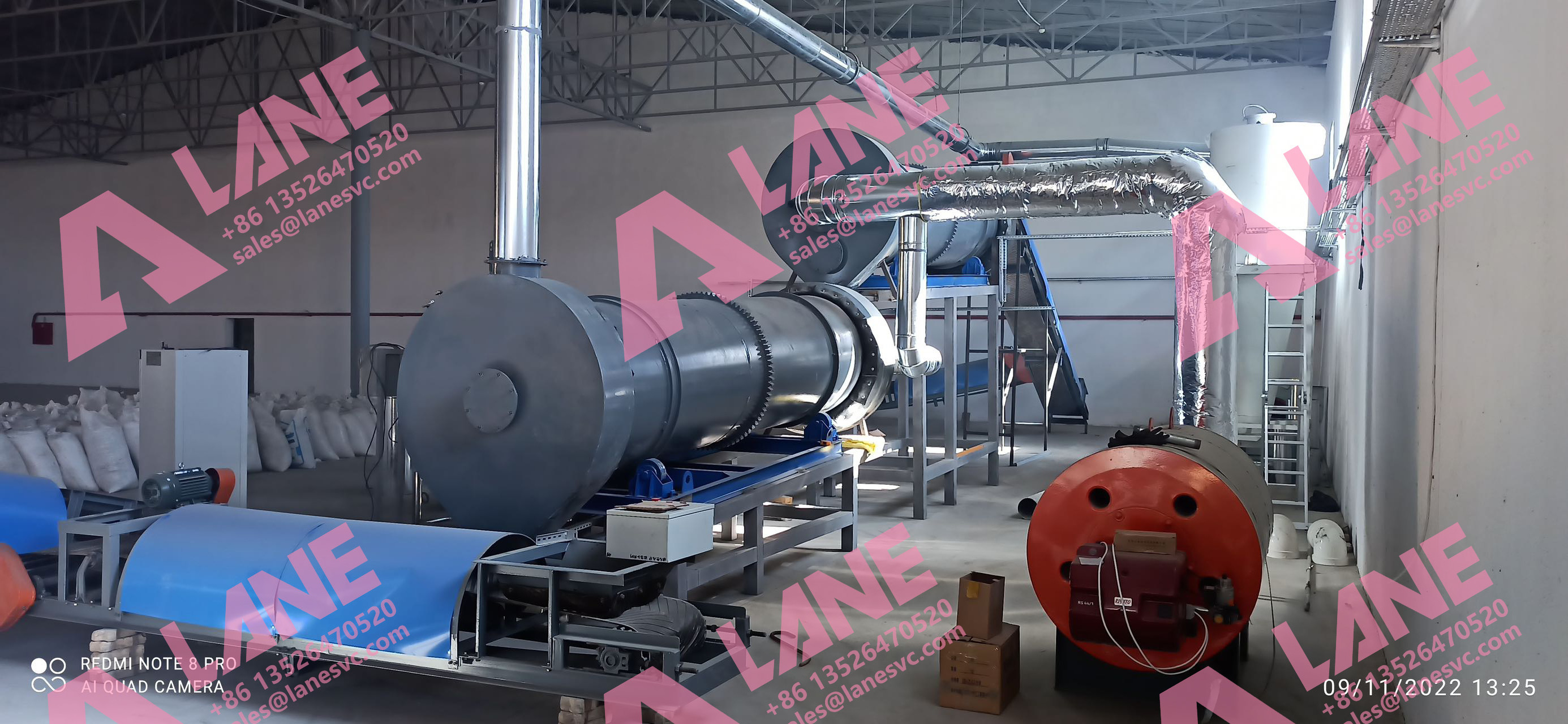

Cases of sulfur urea production lines in Central Asian countries

|

Product Name

|

Yield

|

Detail

|

Speed

|

Power

|

|

Dynamic batching System

|

PVC drive belt: width 0.5m, length 2m

|

1.1-2.2KW

|

SBD series reducer

|

1450r/min

|

|

Bucket Elevator

|

Maximum feeding size: 25-55cm

|

Hopper width: 160-400mm

|

Bucker type Q/H: 12/22 m3/h

|

1.4m/h

|

|

Double shaft Mixer

|

6-22t/h

|

1-30KW

|

4950*1650*800mm

|

1450r/min

|

|

Rotary Drum Granulator

|

1-20t/h

|

ZY series reducer

|

11r/min

|

1450r/min

|

|

Rotary Drum Drying Machine

|

1-25t/h

|

5.5-22KW

|

5r/min

|

1450r/min

|

|

Rotary Drum Cooling Machine

|

1-20t/h

|

5.5-22KW

|

5r/min

|

1450r/min

|

|

Rotary Screen Machine

|

1-23t/h

|

3-7.5KW

|

ZQ series reducer

|

1450r/min

|

|

Rotary Coating Machine

|

5-15t/h

|

7.5-15KW

|

11r/min

|

1450r/min

|

|

Double Station Packing Machine

|

10-20 bags/min

|

Power current: 4/16 KW/\A

|

1600*1200*3200mm

|

50Hz/60Hz/220V/380V

|

Real customer sulfur urea production line on-site display

Our Service

Pre-sale

Our account manager will communicate with you the product requirements related to your machine

We offer free product plans, packaging drawings and 3D renderings to save your budget

We will provide our own quotation and proof of our machines

We have a professional R & D department, to provide you with the most professional technical support

We can make granulation experiment according to your raw materials

On sale

1、During the production of the equipment, we will feed back the production progress to you

2、We support customer on-site inspection,video inspection, third party inspection, factory inspection agency inspection

3、

We can provide certificate of origin, customs clearance and other certificates

4、We offer you a free test service before the machine leaves the factory

5、

We also provide equipment packing diagram

After sale

1、If you need to install, we have a professional overseas installation team ,

We will provide you with installation drawings or a video guide for making the installation

2、We support to provide you with free accessories within one year of purchase of machine equipment

3、We will provide a five year warranty on important parts of the equipment

Transaction Customer

Customer evaluation & Production site

This is part of our customer site and customer praise display, if you want to communicate with these customers, please contact us

Hot Searches