- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

7.5KW

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

1300*1100*1200MM

-

Raw material:

-

corn powder and soyabean cake and fish powder and so on

-

Function:

-

Aniaml pet Feed Puffed Pellet Machine

-

Pellet size:

-

0.9-12mm

-

Feature:

-

Multifunctional High Efficiency

-

Keywords:

-

Poultry Feed Processing Equipment

-

Related machine:

-

mixer , conveyor, dryer , flavour

-

Final product:

-

different shape

-

Spare parts:

-

Die+screw

-

Suit for:

-

Aquatic Products and poultry pet

Quick Details

-

Marketing Type:

-

New Product

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

JOCONN

-

Voltage:

-

380V/50HZ

-

Power:

-

7.5KW

-

Weight:

-

200 KG

-

Dimension(L*W*H):

-

1300*1100*1200MM

-

Raw material:

-

corn powder and soyabean cake and fish powder and so on

-

Function:

-

Aniaml pet Feed Puffed Pellet Machine

-

Pellet size:

-

0.9-12mm

-

Feature:

-

Multifunctional High Efficiency

-

Keywords:

-

Poultry Feed Processing Equipment

-

Related machine:

-

mixer , conveyor, dryer , flavour

-

Final product:

-

different shape

-

Spare parts:

-

Die+screw

-

Suit for:

-

Aquatic Products and poultry pet

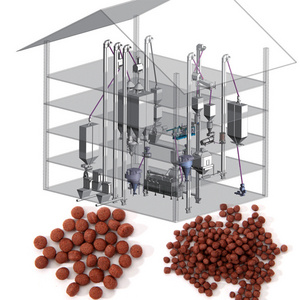

dog food making machine dry/dog food extruder machine/dog pet food making machine for pet feed producing

whatsapp/wechat +86 15093228930

| 1 | Pet food is very different from traditional feed production methods. The dog pet food making machine uses corn, soybean (bean cake) animal scraps, etc. as raw materials, which can be expanded directly into the machine to produce different particles. The shape is novel, the taste is unique, and nutrition Rich and delicate organization, suitable for dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, mink, fox and other pet feeds. It is suitable for farmers, small and medium-sized feed factories. |

| 2 | The floating extruded feed produced by the dog pet food making machine can float on the water surface for at least 12 hours without foaming. Fish and poultry like to eat and digest easily. dog pet food making machine is convenient to observe the food intake of fish without causing waste of feed. Will not pollute water quality. |

| 3 | The high-temperature and high-pressure materials can effectively remove harmful bacteria such as Escherichia coli and Salmonella, ensuring the sanitation of feed, conducive to protein denaturation and starch gelatinization, and easy to be absorbed by fish, shrimp, frogs, crabs and livestock. Generally, puffed floating fish feed can save 8%-15% than powdered or granular feed. |

| 4 | The pet food extruder can also produce cooked sinkable aquatic feed and livestock pellet feed, which can eliminate most of the toxins and anti-trypsin and urease of anti-nutritional factors in the material species, which is beneficial to the digestion and absorption of animals. dog pet food making machine Improve the digestive utilization of nutrients. |

| 5 | dog pet food making machine Scope of application: Suitable for frogs, aquatic products, ornamental fish, pet feed farmers, small and medium-sized feed factories and scientific research rooms. |

|

Model |

JC P40- A |

JC P50- A |

JC P60- A |

JC P70-B |

JC P80-B |

JC P90-B |

JC P120-B |

JC P135-B |

JC P160-B |

JC P200-B |

|

Capacity |

30-40kg/h |

60-80kg/h |

120-150kg/h |

180-200kg/h |

200-300kg/h |

300-400kg/h |

500-600kg/h |

700-800kg/h |

1000-1200kg/h |

1800-2000kg/h |

|

Main power |

5.5kw |

7.5-11kw |

15kw |

18.5kw |

22kw |

37kw |

55kw |

75kw |

90kw |

132kw |

|

Feeding power |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

0.6kw |

0.6kw |

0.8kw |

1.1kw |

1.5kw |

|

cutting power |

0.4kw |

0.4kw |

0.4kw |

0.4kw |

0.6kw |

0.8kw |

1.5kw |

2.2kw |

3.0kw |

3.0-4.0kw |

|

Screw Diameter |

φ40 |

φ50 |

φ60 |

φ70 |

φ80 |

φ90 |

φ120 |

φ133 |

φ155 |

φ195 |

|

F eed pellet size |

animal finished products :5-12mm, fish finished products:0.9-12mm |

|||||||||

|

A pplication |

Aquatic feed pellets: fish, shrimp, frog ,crab etc. |

|||||||||

|

Pet feed pellets: dog, cat, rabbit, bird, chicken, goose, duck, pig ,fox etc. |

||||||||||

| 1 | pet food extruder machine Adopt the soft knife fitting form to realize the stepless speed change, which can cut the discharge into the product of the required length without burr. |

| 2 | The screw sleeve and screw are made of special wear-resistant high-temperature and high-humidity material 38 chromium molybdenum aluminum, which are tempered and then heat-treated to form, which has the advantages of wear resistance and long life. |

| 3 | Equipped with a unique pressurizing die device to ensure the output and quality of feed; equipped with an electric heating device to increase the feed expansion rate. |

| 4 | The replacement of the discharge template is simple, and the production of feeds with different apertures only needs to replace the required aperture template. |

If you are interested or have any questions , please feel free to contact me by namecard below , or scan the QR code for quick talk on wechat .we are on service 24hrs .