- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

VANEST

-

Model Number:

-

LBR1000

-

Power:

-

As Requirements

-

Material:

-

Standard Packaging

-

Marketing Type:

-

Hot Product 2022

-

Weight (KG):

-

14700 kg

-

Product Name:

-

Scrap Car Soft Package Lithium Ion Battery Recycling Machine

-

Application:

-

Lithium Battery Recycle

-

Certification:

-

CE

-

Key Words:

-

Car Soft Package Battery Separating System

-

Raw Material:

-

Scrap Lithium ion Battery, Car, Mobile, Phone Batteries

-

Final product:

-

Lithium Cobalt Powder, Copper, Aluminum

-

Voltage:

-

According To Your Country Voltage

-

Color:

-

Customized Color

-

MOQ:

-

1 Unit

-

Machine material:

-

Cast Iron

Quick Details

-

Production Capacity:

-

1000kg/h

-

Applicable Industries:

-

Lithium Powder Recycling

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

VANEST

-

Model Number:

-

LBR1000

-

Power:

-

As Requirements

-

Material:

-

Standard Packaging

-

Marketing Type:

-

Hot Product 2022

-

Weight (KG):

-

14700 kg

-

Product Name:

-

Scrap Car Soft Package Lithium Ion Battery Recycling Machine

-

Application:

-

Lithium Battery Recycle

-

Certification:

-

CE

-

Key Words:

-

Car Soft Package Battery Separating System

-

Raw Material:

-

Scrap Lithium ion Battery, Car, Mobile, Phone Batteries

-

Final product:

-

Lithium Cobalt Powder, Copper, Aluminum

-

Voltage:

-

According To Your Country Voltage

-

Color:

-

Customized Color

-

MOQ:

-

1 Unit

-

Machine material:

-

Cast Iron

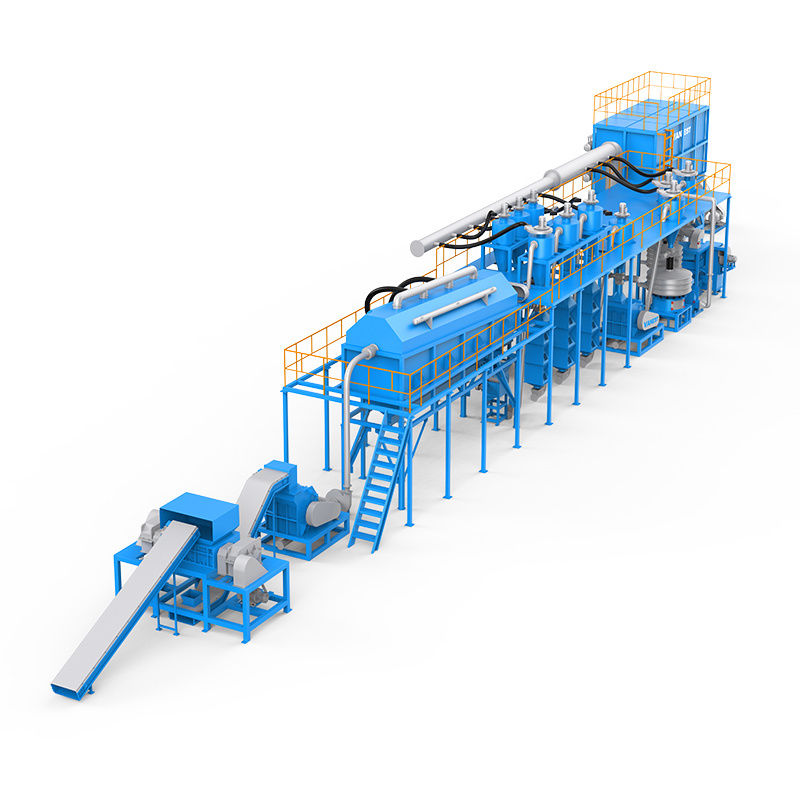

VANEST EV Battery Recycling Machine Lithium Ion Battery Recycling Plant

Battery Recycling Machine

BACKGROUND

The pretreatment process of Lithium Batetry Recycling Plant mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

RAW MATERIALS

The lithium battery recycling plant is used for dismantling and recycling the Soft package battery, cellphone battery,Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

FINAL PRODUCTS

-- Dust Collector -- Spray Tower -- UV Photooxygen catalytic activated carbon AIO

1, Shredder: Shredded lithium batteries into smaller pieces, about 25mm.

2, No.1 Hammer crusher:

Further hammer crush material to 10mm pieces

.

3, Rotary Screen : Collect 55%~60% battery powder .

4, Magnetic Separator: Separate iron from the materials.

5, Air Sorter:

Separate diaphragm, separation rate about 99%.

6, No.2 Crusher: Further crush the material to 6mm pieces.

7, Spin Vibration Sieve: Collect 35% battery powder. Up till now about 95% battery powder is collected.

8, High Speed Vortex Mill:

Crush and grind the materials(mainly copper and aluminum) to form granules with consistent specifications.

9, Spin Vibration Sieve: Collect 4~5% battery powder. Up till now about 99% battery powder is collected.

10, Gravity Sorter: Separate copper from aluminum, separation rate about 99%

ENVIRONMENTALLY FRIENDLY EQUIPMENT

The air purification equipment of this production line has a very good performance.There are

Dust Collector

facility,

Spray Tower

and

UV Photooxygen catalytic activated carbon AIO

device used to absorb odors andpulse dust collection system for dust adsorption.

|

MODEL

|

CAPACITY

|

|

|

LBR500

|

500kg/h

|

|

|

LBR1000

|

1000kg/h

|

|

|

LBR1500

|

1500kg/h

|

|

|

WORKING PERFORMANCE

|

|

|

|

RAW MATERIAL

|

Lithium-ion Battery

|

|

|

FINAL PRODUCTS

|

Lithium Cobalt Powder, Graphite Powder, Copper, Aluminum, Diaphragm

|

|

|

* Working voltage:380±10V(voltage can be customized to meet your local condition);

|

|

|

|

FEATURE ITEM

|

SORTING REQUIREMENTS

|

|

Metal Recovery Rate

|

≥99%

|

|

Battery Powder Recovery Rate

|

≥99%

|

|

Diaphragm Recovery Rate

|

≥99%

|

Hot Searches