- Product Details

- {{item.text}}

Quick Details

-

Torque Capacity:

-

Custom

-

Model Number:

-

Custom, According to drawing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Custom

-

Name:

-

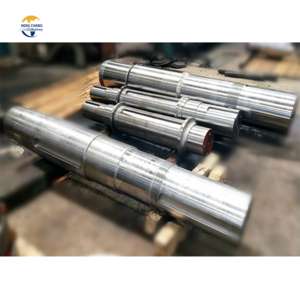

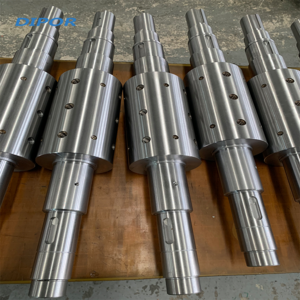

Crusher Shaft

-

Process:

-

Lathing, milling,grinding,drilling

-

Standard:

-

ISO,DIN,JIS

-

Packaging:

-

Adapting to transport

-

Delivery Time:

-

15-30 days

-

Certification:

-

ISO

-

OEM Service:

-

YES

Quick Details

-

Weight (KG):

-

820

-

Core Components:

-

Shaft

-

Material:

-

Steel

-

Torque Capacity:

-

Custom

-

Model Number:

-

Custom, According to drawing

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Custom

-

Name:

-

Crusher Shaft

-

Process:

-

Lathing, milling,grinding,drilling

-

Standard:

-

ISO,DIN,JIS

-

Packaging:

-

Adapting to transport

-

Delivery Time:

-

15-30 days

-

Certification:

-

ISO

-

OEM Service:

-

YES

Why Choose Us

We offer One-stop service From raw material organization to processing production and assembly .

professional engineer team to ensure the good quality.

High-precision CNC processing equipments.

Product Description

Custom large Forging Steel cold rolling mill work roll

The work mill roller shall be a pair of directly adjacent shafts connected by transmission pairs (gears, pulleys, sprockets, etc.). driving shaft is closer to the power source .on the contrary, the passive shaft is similar to the working shaft, it is mainly used in lathes, milling machines, fans, conveyors, injection molding machines, processing centers, steam turbines, drilling machines, hydraulic turbines, machinery industry, etc.

|

Material

|

Alloy steel,Carbon steel,Carburizing steel,Quenched and tempered steel

|

|

Heat treatment

|

Normalizing,Annealing,Quenching&Tempering, Surface Quenching,Case hardening

|

|

Machining

|

CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling

|

|

Gear Machining

|

Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,Spiral gear cutting,Gear Cutting

|

|

Inspection

|

Chemical Composition Test,Ultrasonic Test,Penetration Test,Radiographic Test,Magnetic Test,Tensile Strength Test,Impact

Test,Hardness Test,Dimension Test |

|

Module of Gear

|

8-120

|

|

Gear Grinding

|

MAX. Module 24

|

|

Diameter of Shaft:

|

MAX. 2 200mm

|

|

Length of Shaft

|

MAX. 13 000mm

|

|

Diameter of Gear Wheel

|

MAX.13 000 mm

|

|

Diameter of Spiral Gear

|

MAX. 2 200 mm

|

|

Length of Gear Shaft

|

MAX. 5 000 mm

|

About us

Luoyang Yujie Industry Trade Co,Ltd is established in 2004,is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, welding, bearings, castings and forgings etc. The products are mainly used in the fields of mining, petroleum, cement,steel mill, power plant, sugar factory etc.

All our equipment adopts the advanced CNC machine tools,especially large CNC gantry milling and boring machine, CNC floor-type boring machine.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size. It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

CNC gantry milling and boring machine,CNC machining center equipped with the fourth axis, CNC floor-type boring machine is equipped with the fourth axis and rotary worktable, it can realize five axis machining. The work piece is not limited by the size. It is suitable for machining large module and large size gear, boxes,and large non -standard parts.

Professional technical team, production team and assembly team, supply professional technical support

.

We product the CNC equipment ,so we have professional assembly technicians and electrical engineers. We can provide customers with one-stop service from raw materials, processing to final assembly.

Our company has a series of advanced equipments:XV6032,HXV4032,HXV3017,HXV2017CNC gantry boring and milling machine,TX130CNC floor-type boring machine,DVT-500,HK1600CNC vertical lath,CK6136CNC horizontal lath etc,to ensure high precision and stable performance of products.

All tests conform to ISO 9001 quality management system certification standards,supporting the third party inspection commissioned by customer.

Customer Visit

Certificate

Customer Comments

Contact Us

Address:Jianxi Industrial Park, Luoyang, Henan

Tel:

0379-65163600

Fax:0379-65163600

web:www.yogiemachinery.com

Hot Searches