- Product Details

- {{item.text}}

Quick Details

-

Length:

-

1000mm-6000mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Model Number:

-

CT

-

Side Rail Height:

-

50mm-200mm

-

Max. Working Load:

-

219.4kg/m

-

Product Name:

-

Cable Trunking

-

Color:

-

Customized Color

-

Surface Finish:

-

Galvanized,HDG,Powder Coated

-

Raw material:

-

SS304 SS316 SS316L Q235

-

Thickness:

-

1-3 mm

-

MOQ:

-

10meters

-

OEM:

-

Availabe

-

Certification:

-

ISO CE CQC UL

-

Payment terms:

-

T/T

Quick Details

-

Type:

-

Solid Through

-

Material:

-

FRP,SS,Steel

-

Width:

-

50mm*1200mm

-

Length:

-

1000mm-6000mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HF

-

Model Number:

-

CT

-

Side Rail Height:

-

50mm-200mm

-

Max. Working Load:

-

219.4kg/m

-

Product Name:

-

Cable Trunking

-

Color:

-

Customized Color

-

Surface Finish:

-

Galvanized,HDG,Powder Coated

-

Raw material:

-

SS304 SS316 SS316L Q235

-

Thickness:

-

1-3 mm

-

MOQ:

-

10meters

-

OEM:

-

Availabe

-

Certification:

-

ISO CE CQC UL

-

Payment terms:

-

T/T

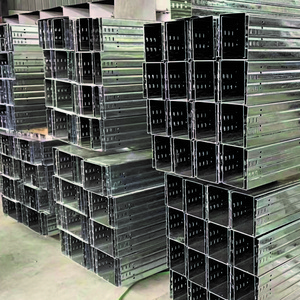

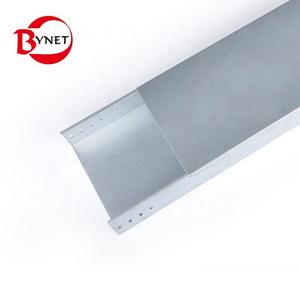

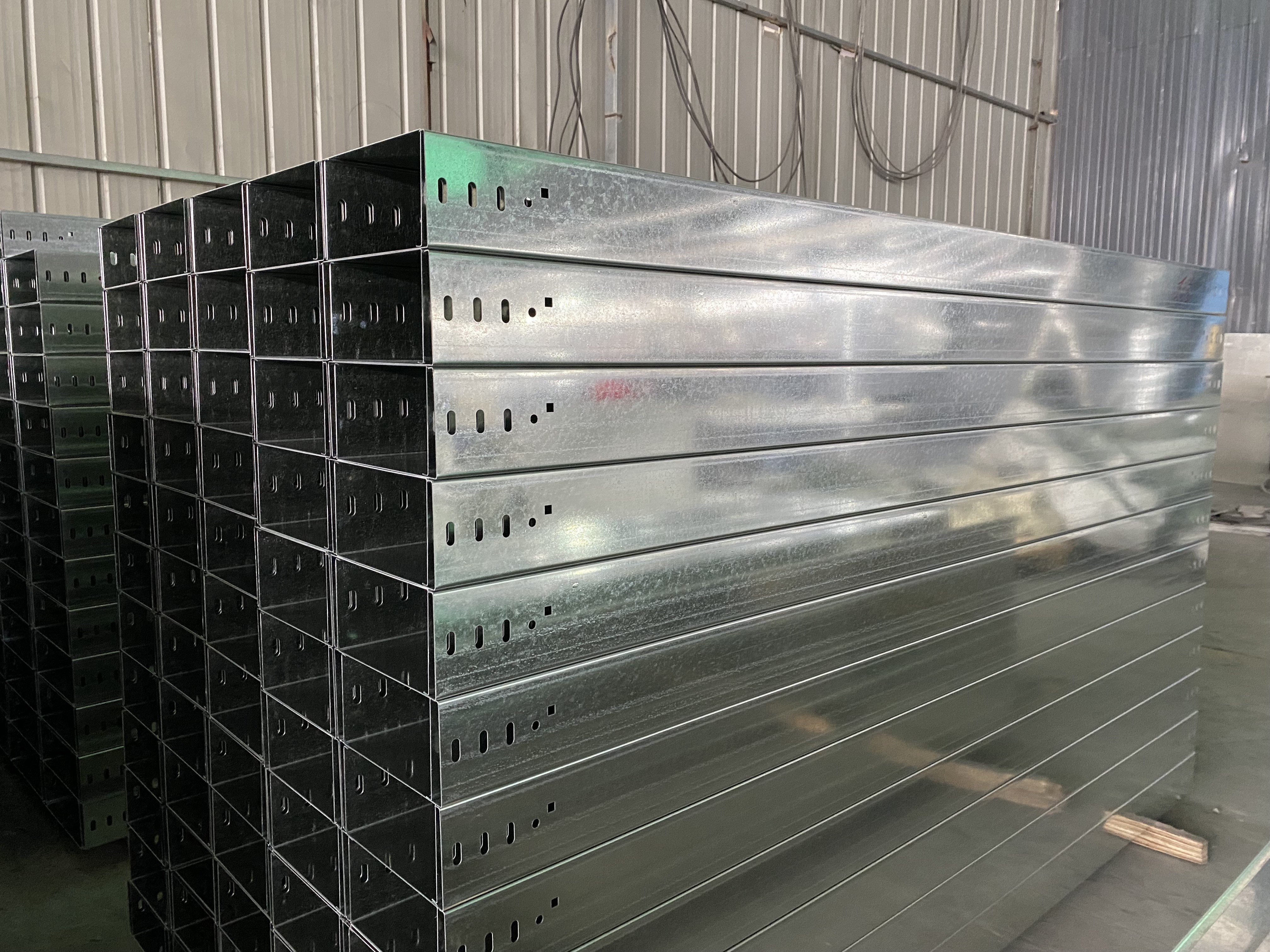

Products Description

Aluminium Cable Tray Cable Trunking

Each piece of our cable trunking has an average length of 3000mm,

we can customize for you if you have any other requirements about the length,

including the height and width about the cable trunking.

Advantages of our cable trunking:

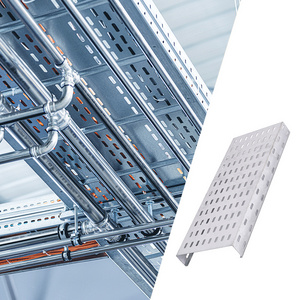

1. Fully enclosed structure: Our cable trunking is a fully enclosed structure with no openings, so it can provide better cable protection and prevent damage to the cables from dust, moisture and other external factors.

2. Suitable for high-sensitivity systems: Due to its fully enclosed design, our cable trunking can effectively shield interference, so it is very suitable for laying computer cables, communication cables, thermocouples and other control cables for high-sensitivity systems.

3. Good corrosion resistance: In heavy corrosive environments,cable trunking can effectively resist corrosion and protect cables from corrosive substances.

4. High reliability: Due to its stable structure and excellent cable protection performance,cable trunking can provide high reliability and reduce cable failures and repair times.

|

Thickness(mm)

|

0.6~3.0mm

|

|

Width(mm)

|

50~600

|

|

Height(mm)

|

50/75/100/150/200

|

|

Length(mm)

|

2440/3000

|

|

Other Material & Finish Available |

Hot Dip Galvanized / HDG – for outdoor use to BS EN ISO 1461

Stainless Steel SS304 / SS316 Powder Coated - for indoor use to JG/T3045 Aluminum to AS/NZS1866 Fiberglass Reinforced Plastics / FRP /GRP Fire Rated to AS3013:2005 Electrolytic Polishing – for Stainless Steel use Mill / Mild /Plain Steel to ISO 4995 |

|

Product Size

|

Width 25-900mm with slotted Thickness: 0.8mm-3.0mm

length is cut according to customer's requirements

U or C shape with standard AISI, ASTM, GB,BS,EN,JIS,DIN or customer's drawings |

|

Product Material and Surface

|

· Material: carbon steel aluminum stainless steel

· Surface coating: Galvanized Hot Dipped Galvanizing Electrolytic Galvanizing Powder coating Neomagnal Anodizing |

|

Corrosion Rating of Galvanizing

|

For example

Outdoor:Atmospheres with low contamination levels. Mostly rural areas.Indoor:Unheated buildings with possible condensation, such as warehouses and sports halls. Galvanization wear:0,1 μm - 0,7 μm in a year |

|

Corrosion Rating of Hot Dipped Galvanized

|

For example

Indoor:Production premises with high humidity levels and some impurities in the air, such as food industry facilities. Outdoor:Urban and industrial atmosphere with medium sulphur dioxide levels. Coastal areas with low salinity levels. Galvanization wear:0,7 μm - 2,1 μm in a year Indoor:Chemical industry production plants, coastal shipyards and boatyards. Outdoor:Industrial areas and coastal areas with medium salinity levels.Galvanization wear:2,1 μm - 4,2 μm in a year |

Good Quality Makes Us Different

* All support channel products are produced by ISO9001 or CE certified mill

* All support channel products are EN10204 3.2 Certified

* Non-destructive Testing Report are available if required

* Surface Treatment Report are available if required

* Mechanical Testing Report are available if required

* All support channel products are produced by ISO9001 or CE certified mill

* All support channel products are EN10204 3.2 Certified

* Non-destructive Testing Report are available if required

* Surface Treatment Report are available if required

* Mechanical Testing Report are available if required

Moreover,we also provide various accessories which are used for support &installation of our cable trunking.

Hot Searches