- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

1800L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

China

-

Brand Name:

-

Gate

-

Voltage:

-

380V, 50HZ

-

Dimension(L*W*H):

-

7980*2800*5290mm

-

Power (kW):

-

36 kW

-

Elevator Power:

-

1.5kw

-

Rotate Speed:

-

13 r/min

-

Max Materials Size:

-

6mm

-

Capacity:

-

5-10 tons per hour

-

Function:

-

mix NPK materials

-

warranty:

-

5 years

-

Product name:

-

BB fertilizer mixer

-

Name:

-

Fertilizer Mixing

-

MOQ:

-

1 Set

Quick Details

-

Barrel Volume (L):

-

2000 L

-

Max. Loading Volume (L):

-

2000 L

-

Range of Spindle Speed(r.p.m):

-

15 - 20 r.p.m

-

Max. Loading Capacity:

-

1800L

-

Weight (KG):

-

500 KG

-

Place of Origin:

-

China

-

Brand Name:

-

Gate

-

Voltage:

-

380V, 50HZ

-

Dimension(L*W*H):

-

7980*2800*5290mm

-

Power (kW):

-

36 kW

-

Elevator Power:

-

1.5kw

-

Rotate Speed:

-

13 r/min

-

Max Materials Size:

-

6mm

-

Capacity:

-

5-10 tons per hour

-

Function:

-

mix NPK materials

-

warranty:

-

5 years

-

Product name:

-

BB fertilizer mixer

-

Name:

-

Fertilizer Mixing

-

MOQ:

-

1 Set

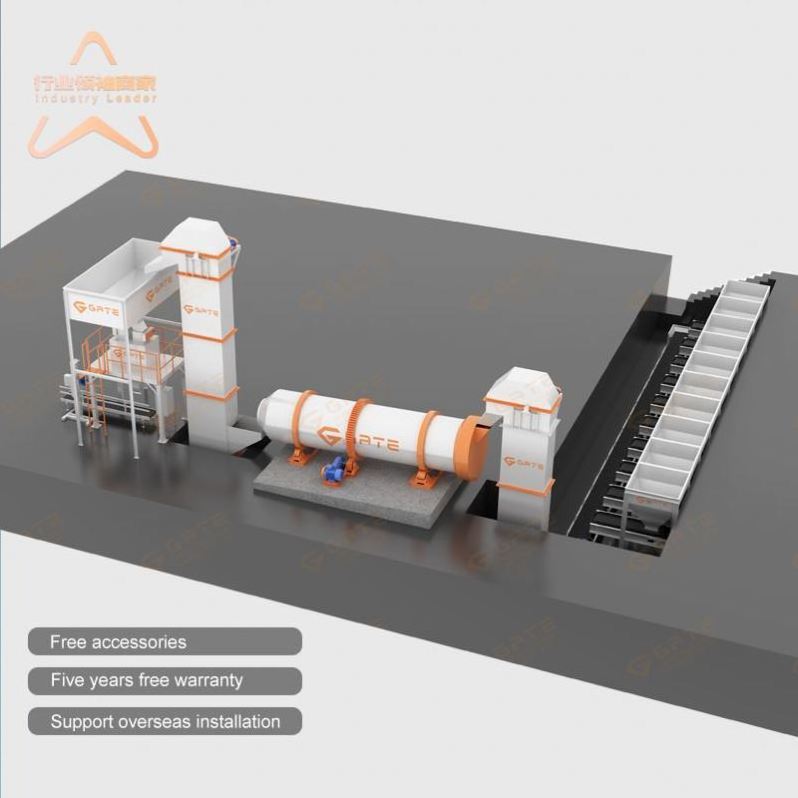

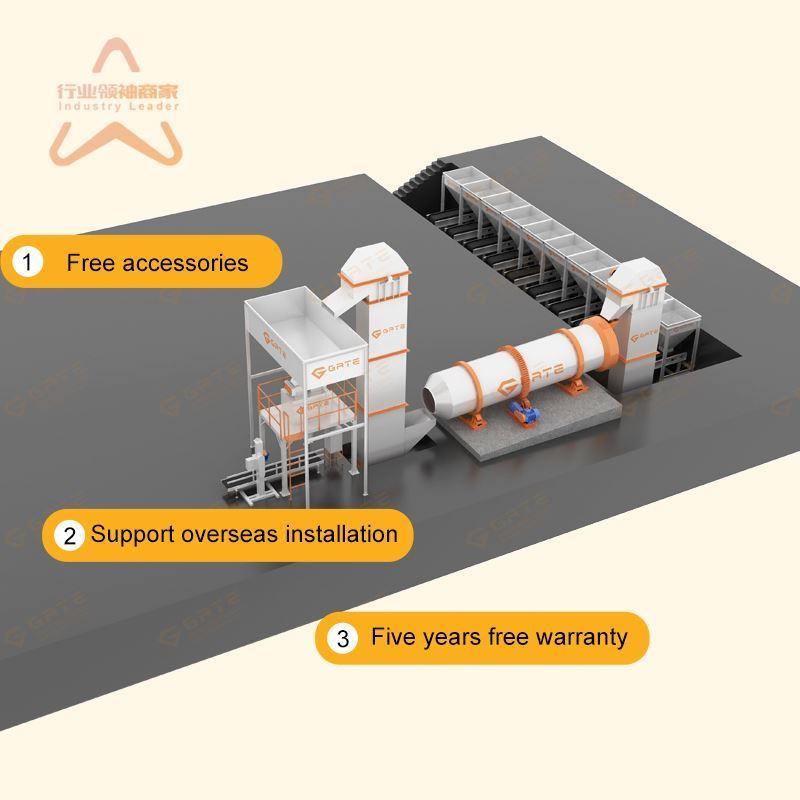

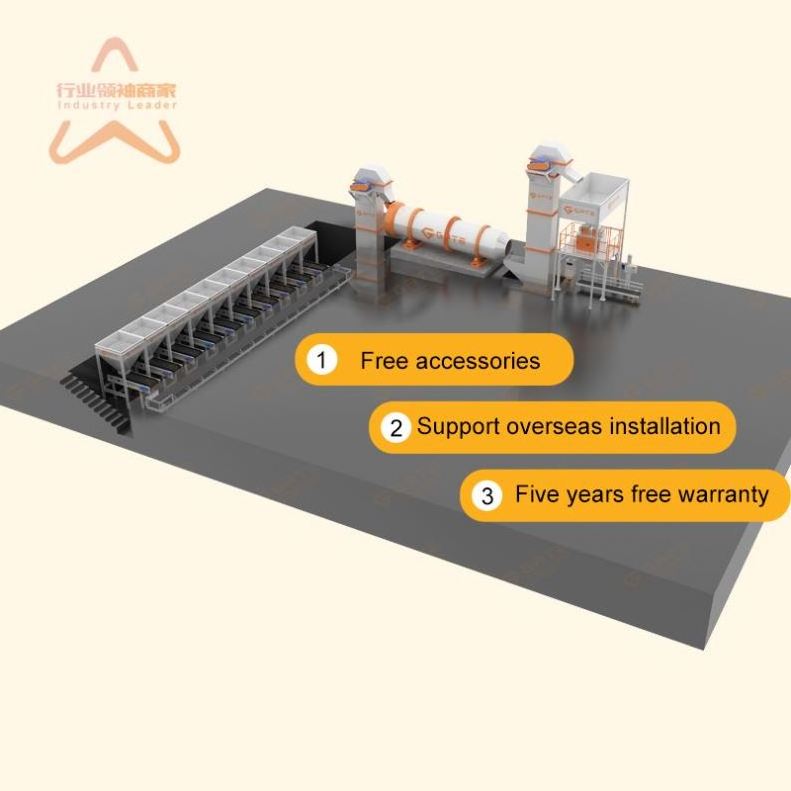

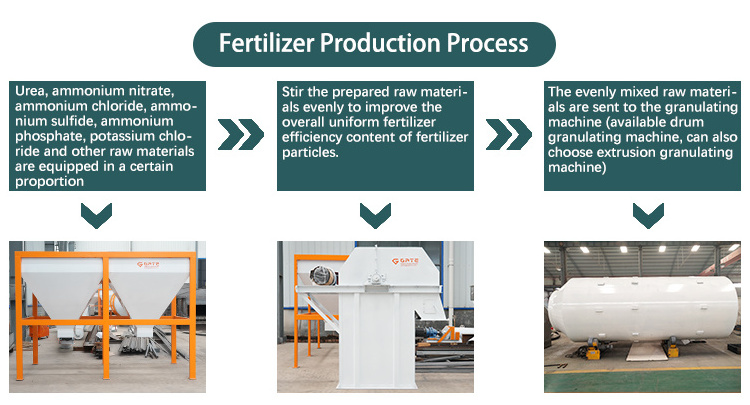

BB Fertilizer Production Line

①The fertilizer pellets are

packaged and sold

②Used for wheat, peanut, corn, soybean and other crops or fruit trees as base fertilizer.

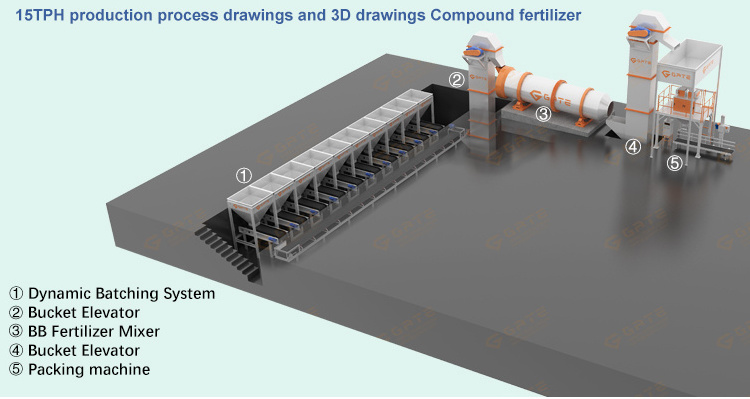

Production Process Diagram And 3D Diagram Of 15T/H Bb Fertilizer Production Line

3D diagram of 15 T/H BB fertilizer production line

|

Product name

|

Machine parameters

|

|

|

Speed

|

||

|

Dynamic Batching System

|

PVC drive belt: width 0.5 m, length 2 m

|

1.1-2.2KW

|

SBD series reducer

|

1450r/min

|

||

|

Bucket Elevator

|

Maximum feeding size: 25-55cm

|

Hopper width: 160-400mm

|

Bucket type Q/H: 12/22m ³/ h

|

1.4m/h

|

||

|

BB Fertilizer Mixer

|

500 L

|

7.5 kW

|

380v or custom-made

|

1450r/min

|

||

|

Bucket Elevator

|

Maximum feeding size: 25-55cm

|

Hopper width: 160-400mm

|

Bucket type Q/H: 12/22m ³/ h

|

1.4m/h

|

||

|

Ton charter aircraft

|

0-40 Bag/H

|

5.5KW

|

1600x1600x2800mm

|

AC380V

|

||

Production Process Diagram And 3D Diagram Of 50T/H BB Fertilizer Production Line

What can I do for you

Pre-sale

Our account manager will communicate with you the product requirements related to your machine

We offer free product plans, packaging drawings and 3D renderings to save your budget

We will provide our own quotation and proof of our machines

We have a professional R & D department, to provide you with the most professional technical support

We can make granulation experiment according to your raw materials

On sale

1,During the production of the equipment, we will feed back the production progress to you

2,We support customer on-site inspection,video inspection, third party inspection, factory inspection agency inspection

3,

We can provide certificate of origin, customs clearance and other certificates

4,We offer you a free test service before the machine leaves the factory

5,

We also provide equipment packing diagram

After sale

1,If you need to install, we have a professional overseas installation team ,

We will provide you with installation drawings or a video guide for making the installation

2,We support to provide you with free accessories within one year of purchase of machine equipment

3,We will provide a five year warranty on important parts of the equipment

Transaction Customer

Customer evaluation & Production site

This is part of our customer site and customer praise display, if you want to communicate with these customers, please contact us

Hot Searches