17 years of OEM/ODM magnetic material manufacturing experience, 3000 square meters of manufacturing plant, one-stop supplier of

services from raw materials to processing electroplating finished products.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

China Dongguan Huanlin Magnetic Industry Co. LTD

-

Model Number:

-

N33 N35 N38 N40 N42 N45 N48 N50 N52 N55 etc

-

Material:

-

Sintered Neodymium-iron-boron Magnet

-

Product Name:

-

Permanent Strong Neodymium Magnet

-

Size:

-

Customized Magnet Size

-

Coating:

-

Epoxy.Black Epoxy. Nickel.Gold Silver.etc

-

Magnetism direction:

-

Thickness, Axial, Radial, Diametrically, Multi-poles

-

Usage:

-

Industrial Usage

-

Certification:

-

ROHS

-

Color:

-

Bright Silver.Black.others

-

MOQ:

-

100pcs

Quick Details

-

Tolerance:

-

±1%

-

Grade:

-

Rare earth super strong NdFeb magnets, N35-N52 (M.H.SH.UH.EH.AH)

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

China Dongguan Huanlin Magnetic Industry Co. LTD

-

Model Number:

-

N33 N35 N38 N40 N42 N45 N48 N50 N52 N55 etc

-

Material:

-

Sintered Neodymium-iron-boron Magnet

-

Product Name:

-

Permanent Strong Neodymium Magnet

-

Size:

-

Customized Magnet Size

-

Coating:

-

Epoxy.Black Epoxy. Nickel.Gold Silver.etc

-

Magnetism direction:

-

Thickness, Axial, Radial, Diametrically, Multi-poles

-

Usage:

-

Industrial Usage

-

Certification:

-

ROHS

-

Color:

-

Bright Silver.Black.others

-

MOQ:

-

100pcs

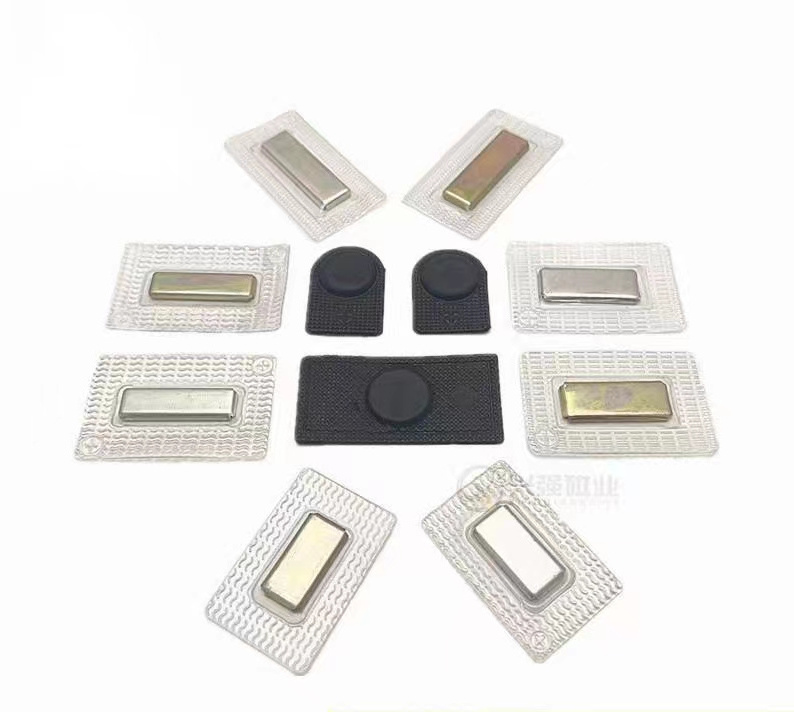

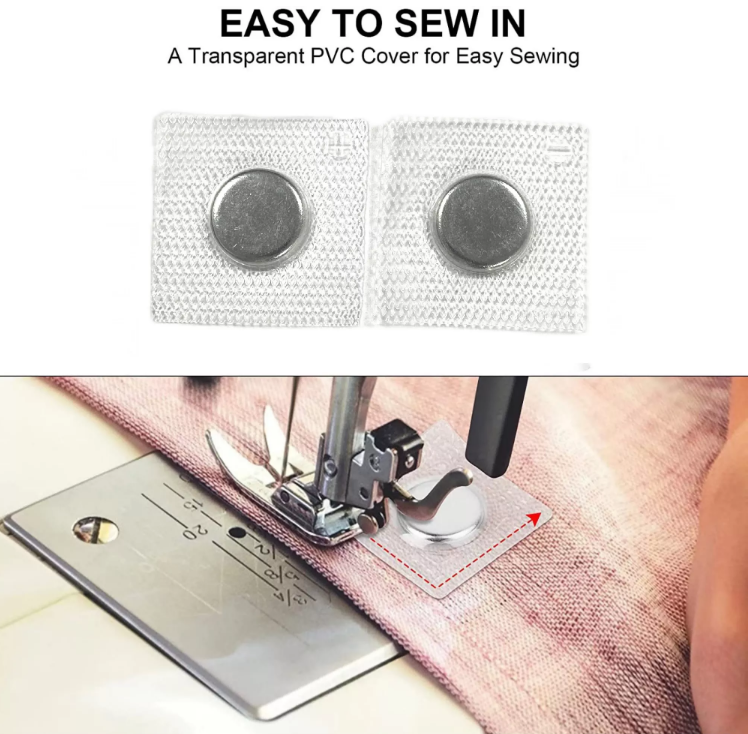

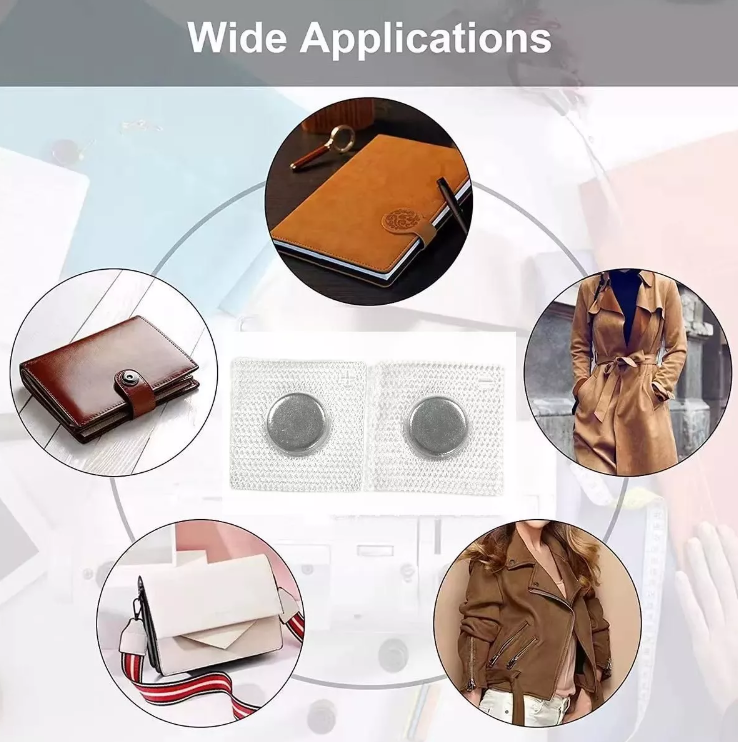

magnet manufacturer custom special strong PVC Waterproof Sewing Magnet strong magnetic strips magnet for clothing 60X10X3mm

Why Choose Us

Welink: Your reliable supplier

|

* Fast response and good quality8-12 days fast delivery Quote within an 15 minutes From 9:00 to 20:30 Beijing time.

|

|

* One-stop shopping for magnetic products, saving your time, accessories can also be purchased for you

|

|

* The product has

CE ROHS MSDS California 65 RECAH

certification

|

|

* Free samples in stock for testing

|

|

* 100% on-time delivery

|

|

*

Support O/A credit, the longest period is 30/60 days, (Platinum and above)

|

|

* Urgent order service is supported Negotiable delivery time We have many standard products in stock

|

|

*contact me now

:

magnet-sale08@dghuanlin.com

|

Product Description

ring ndfeb magnet n52 arc block ring disc magnet

Neodymium magnet, the third generation of the rare-earth permanent magnet, is the most powerful and advanced permanent magnet

today. Neodymium is named as"Magnet King" for its high remanence, high energy. Moreover, It has high performance and low cost

because of the rich rare earth resources in China and the ever-changing production process and technological

progress. We have a complete industrial chain from raw material blanks, cutting, electroplating to standard packaging. we can make

the products you want according to your needsIt can be easily formed into various sizes and different shapes,

today. Neodymium is named as"Magnet King" for its high remanence, high energy. Moreover, It has high performance and low cost

because of the rich rare earth resources in China and the ever-changing production process and technological

progress. We have a complete industrial chain from raw material blanks, cutting, electroplating to standard packaging. we can make

the products you want according to your needsIt can be easily formed into various sizes and different shapes,

How to Customize a Magnet

How to choose the grade of neodymium magnet

Neodymium magnets are graded according to the material from which they are made. The higher the rating (the number after the "N"), the stronger the magnet and the higher the value. The highest grade of neodymium magnets currently available is N54. Any letters after the rating refer to the maximum temperature rating of the magnet. If there is no letter after the grade, the standard temperature of the magnet is 80 °C. Temperature ratings are standard temperature (no letter) followed by - M (100 °C) - H (120 °C) - SH (150 °C) - UH (180 °C) - EH (200 °C) - AH ( 220 °C) C)°C) For example: if the working temperature is 100 degrees, you need to select the H gear, and the temperature resistance of the magnet needs to be higher than the actual use.

We accept customized services:

1) Shape and Dimension Requirements

2) Material and coating requirements

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

7)Packaging and LOGO exclusive customization

3) Processing according to design drawings

4)Requirements for Magnetization Direction

5) Magnet Grade Requirements

6) Surface treatment requirements (plating requirements)

7)Packaging and LOGO exclusive customization

|

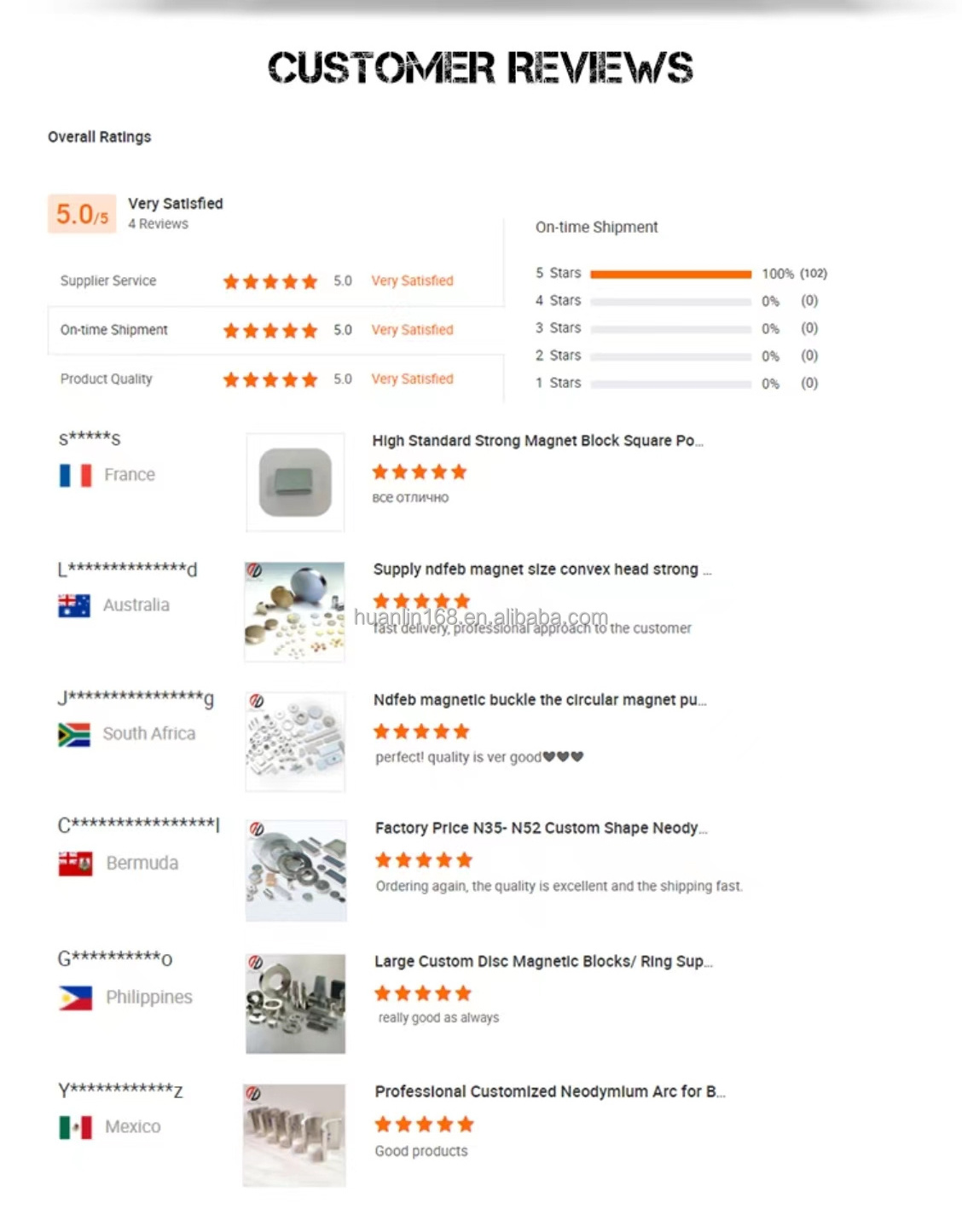

17 years experience manufacturer of neodymium magnetic materials

2 Years Verified Golden Supplier In Alibaba

High Quality N52 Strong NdFeB magnet

Samples and Trial Orders Are Most Welcome

|

|

|

||

|

Material

|

Sintered Neodymium-Iron-Boron (NdFeB)

|

|

||

|

HS Code

|

8505111000

|

|

||

|

Size

|

Various kinds or according to customers' request

|

|

||

|

Shape

|

Disk, square, ring, stick, ball, countersink, cube, cylinder, arc, trapezoid, runway, irregular, etc.

|

|

||

|

Performance

|

N52/Customised ( N35 N38 N40 N42 N45 N48 N50 N52 )(Use within 60°C)

N35M N38M N40M N42M N45M N48M N50M N52M(Use within 90°C)

N35H N38H N40H N42H N45H N48H N50H N52H(Use within 110°C)

N35SH N38SH N40SH N42SH N45SH N48SH N50SH N52SH(Use within 130°C)

N33UH N35UH N38UH N40UH N42UH N45UH(Use within 160°C)

N33EH N35EH N38EH N40EH N42EH N45EH (Use within 180°C)

N33AH N35AH N38AH(Use within 200°C)

|

|

||

|

Coating

|

Ni-Cu-Ni, Nickel / Customised (Zn,Ni-Cu-Ni,Ni,Gold, Silver, Copper, Epoxy, Chrome, etc)

|

|

||

|

Size tolerance

|

±0.05mm for diamater/thickness, ±0.1mm for width/length

|

|

||

|

Magnetization

|

Thickness Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Customzied specific

requirements magnetized Refer to the diagram below) |

|

||

|

Max. Working

Temperature

|

Grade

|

Max. Operating Temperatures

|

||

|

|

N35-N52

|

80°C (176°F)

|

||

|

|

N35M- N52M

|

100°C (212°F)

|

||

|

|

N35H-N52H

|

|||

|

|

N35SH-N52SH

|

150°C (302°F)

|

||

|

|

N33UH-N45UH

|

180°C (356°F)

|

||

|

|

N33EH-N45EH

|

200°C (392°F)

|

||

|

|

N30AH-N38AH

|

220°C (428°F)

|

||

|

Advantage

|

1. High-level Machining Ablity

2. Excellent consistency

3. All shapes can be made

4. Timely delivery guaranteed

5.Low MOQ

|

|

||

custom coating

1. Neodymium magnets are mainly composed of neodymium, iron and boron. The iron in the magnet will rust if exposed to air.

2. That's why all the strong neodymium magnets in our factory are covered with protective coating, the protective coating is very thin (micron level) and has no effect on the adhesion of the magnet.

3. Neodymium magnets are available in many different coating and plating options. The most common coating for neodymium magnets is nickel plating. Although often referred to simply as "nickel plating," this nickel option is actually a three-layer plating consisting of a nickel layer, a copper layer, and a nickel coating.

4. Commonly used nickel (NI-CU-NI), zinc, copper, epoxy resin, gold, silver, passivation, PVC coating, etc.

magnetization direction

The most important thing is to choose the correct magnetization direction

Common directions of magnetization are shown in the figure below:

1>Disc, cylindrical and ring magnets can be magnetized axially or radially.

2> Rectangular magnets can be magnetized by thickness, length or width.

3> Arc magnets can be magnetized radially, by width or thickness.

4>The red in the figure below is the N pole and the white is the S pole

Hot Searches