- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/110V, 220V/110V

-

Year:

-

2021

-

Power (kW):

-

3

-

Weight (KG):

-

23

-

Name:

-

Metal Cutting Saw

-

Weight:

-

23KG

-

Machine Type:

-

Steel Bar cutter

-

Keyword:

-

Circular Saw For Cutting Metal

-

Application:

-

Construction Projects

-

Function:

-

Concstruction

-

Motor power:

-

3KW

-

Blade:

-

10 inch/14 inch

-

Brand:

-

KAIRENEN

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

KAIRUIEN

-

Voltage:

-

220V/110V, 220V/110V

-

Year:

-

2021

-

Power (kW):

-

3

-

Weight (KG):

-

23

-

Name:

-

Metal Cutting Saw

-

Weight:

-

23KG

-

Machine Type:

-

Steel Bar cutter

-

Keyword:

-

Circular Saw For Cutting Metal

-

Application:

-

Construction Projects

-

Function:

-

Concstruction

-

Motor power:

-

3KW

-

Blade:

-

10 inch/14 inch

-

Brand:

-

KAIRENEN

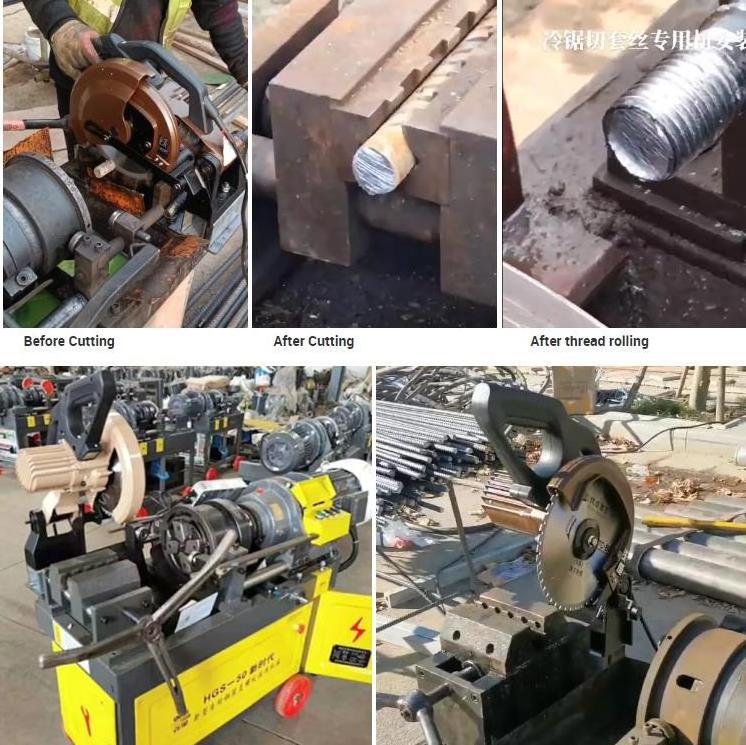

Products Description

KAIRUIEN Metal Tube Cut off Saw Cutter Machines Industrial Cold Steel Saw Cutting Machine

|

Model

|

Power

|

Voltage

|

Saw diameter

|

Motor Rotation

|

Core diameter

|

N.W

|

|

RC-10

|

3000W

|

220V

|

255mm(10 inch)

|

900r/min

|

25.4mm

|

23kg

|

|

RC-14

|

3500W

|

220V

|

355mm(14 inch)

|

700/min

|

25.4mm

|

27kg

|

Feature of KAIRUIEN Metal Tube Cut off Saw Cutter Machines Industrial Cold Steel Saw Cutting Machine

1. The sawing method of cold milling:

The heat generated in the sawing process is very small, which can effectively avoid the change of internal stress and material structure at the cut section. At the same time, the saw blade has a small pressure on the steel pipe, which will not cause deformation of the pipe wall orifice;

2. The quality of the cut end face of the workpiece processed by the high-speed steel cold cutting saw is good:

The optimized cutting method is adopted, the cutting section has high precision, no burr inside and outside, and the cutting surface is smooth and smooth; the workpiece will not change the material due to the high temperature caused by friction; the operator has low fatigue, and the sawing efficiency is improved; there is no spark during the sawing process. , no dust, no noise, environmental protection and energy saving;

3. Long service life:

It can use the saw blade grinder to repeatedly grind the teeth, and the life of the saw blade after grinding is the same as the life of the new saw blade. Improve production efficiency and reduce costs.

4. Metal Cold Cutting machine Special Design for Rebar Thread Rolling Machine

The heat generated in the sawing process is very small, which can effectively avoid the change of internal stress and material structure at the cut section. At the same time, the saw blade has a small pressure on the steel pipe, which will not cause deformation of the pipe wall orifice;

2. The quality of the cut end face of the workpiece processed by the high-speed steel cold cutting saw is good:

The optimized cutting method is adopted, the cutting section has high precision, no burr inside and outside, and the cutting surface is smooth and smooth; the workpiece will not change the material due to the high temperature caused by friction; the operator has low fatigue, and the sawing efficiency is improved; there is no spark during the sawing process. , no dust, no noise, environmental protection and energy saving;

3. Long service life:

It can use the saw blade grinder to repeatedly grind the teeth, and the life of the saw blade after grinding is the same as the life of the new saw blade. Improve production efficiency and reduce costs.

4. Metal Cold Cutting machine Special Design for Rebar Thread Rolling Machine

Details Images

Product packaging

Related Products

Delivery

Our Advantages

Hot Searches