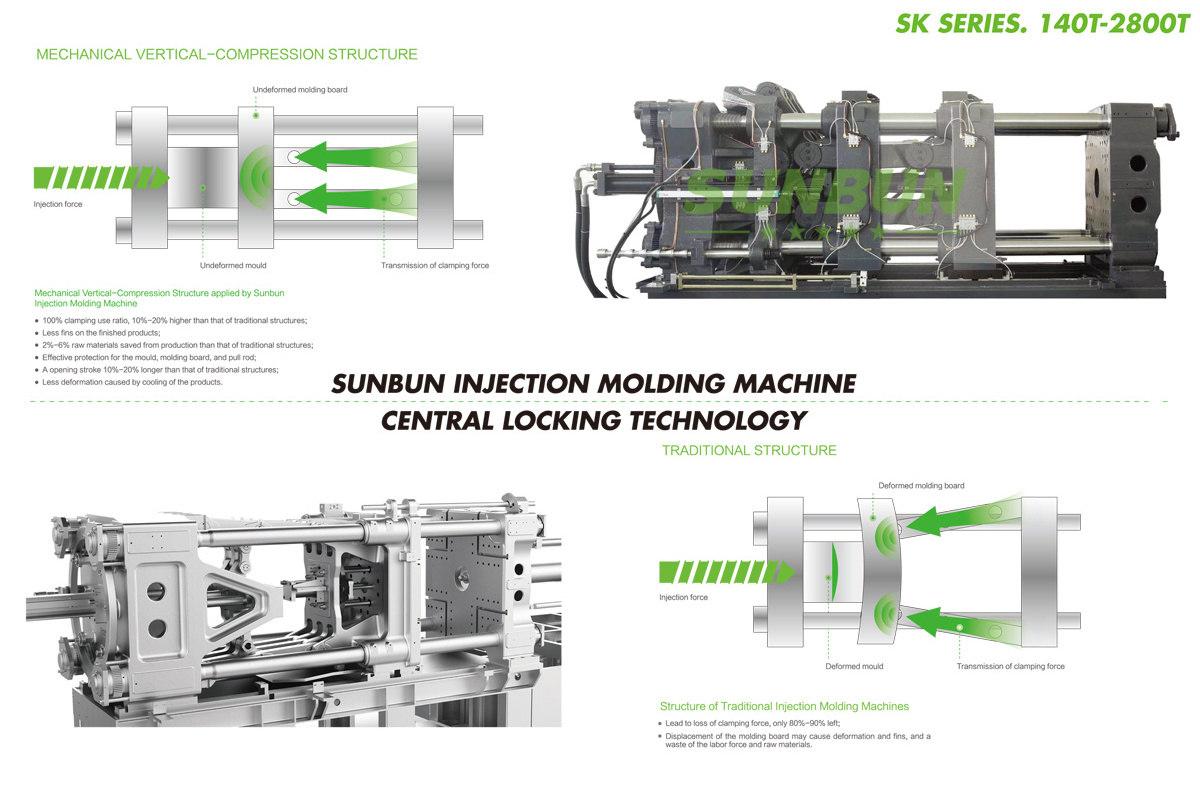

● 100% Clamping Force Ratio, 10%-20% Higher Than Tradtional One

● 2%-6% Raw Material Saved From Tradtional One

● Effective Production For Mold, Mold Board and Pull Rod

●Open Stroke 10%-20% Bigger Than Morlam One

● Less Deformation By CoolIng

● Effective Production For Mold, Mold Board and Pull Rod

●Open Stroke 10%-20% Bigger Than Morlam One

● Less Deformation By CoolIng