Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

15*3.5*3m/15*6*3m

-

Warranty:

-

12 Months

-

Weight:

-

18T

-

Power:

-

170kw/200kw

-

Product name:

-

PS foam food container making production line

-

Model:

-

HR-1080M

-

Collection method:

-

mechanical arm

-

Material:

-

Polystyrene

-

Total weight:

-

16T/18T

-

Frrming area:

-

1000*750/1000*1400/1000*1250/1000*1400

-

Max forming depth:

-

100mm

-

Production efficiency:

-

4~5/S/die 2.8~5s/side

-

Forming pressure:

-

20T/35T

-

Mounted power:

-

170KW/200kw

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HR

-

Model Number:

-

HR-1080

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

15*3.5*3m/15*6*3m

-

Warranty:

-

12 Months

-

Weight:

-

18T

-

Power:

-

170kw/200kw

-

Product name:

-

PS foam food container making production line

-

Model:

-

HR-1080M

-

Collection method:

-

mechanical arm

-

Material:

-

Polystyrene

-

Total weight:

-

16T/18T

-

Frrming area:

-

1000*750/1000*1400/1000*1250/1000*1400

-

Max forming depth:

-

100mm

-

Production efficiency:

-

4~5/S/die 2.8~5s/side

-

Forming pressure:

-

20T/35T

-

Mounted power:

-

170KW/200kw

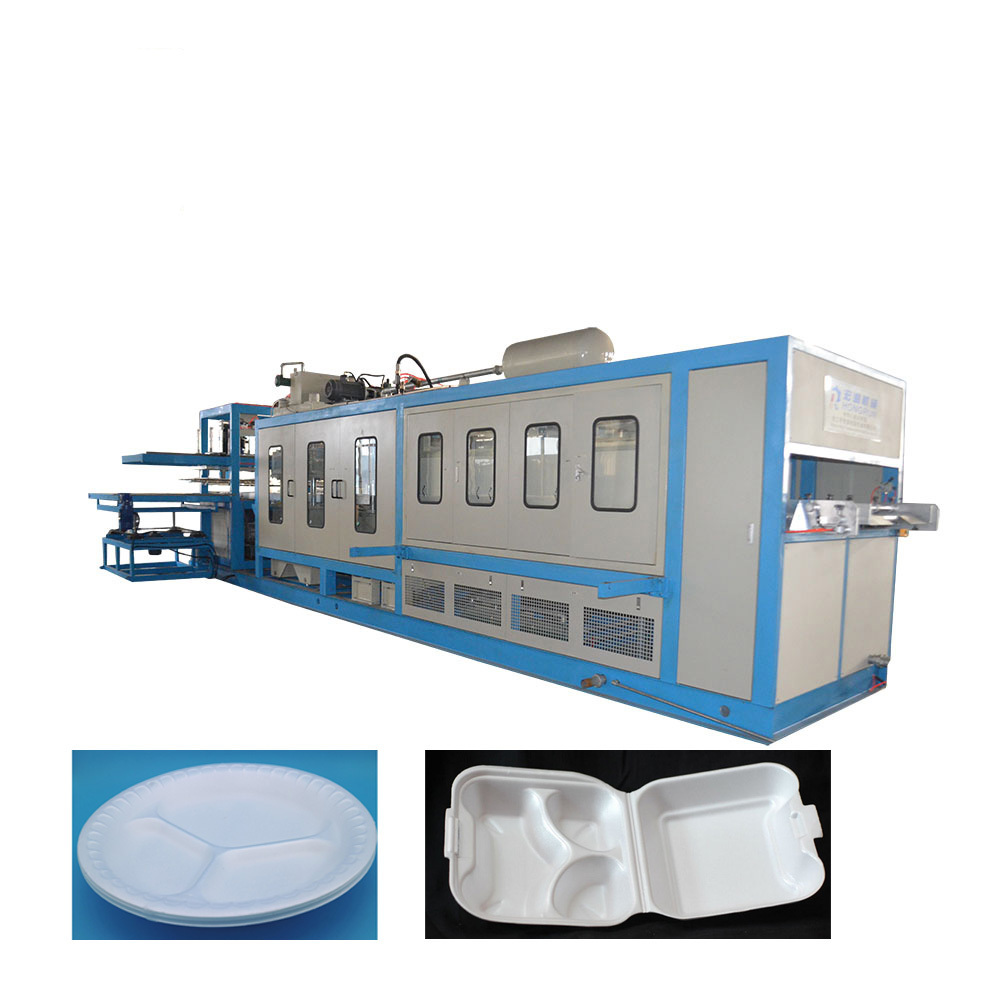

PS foam food container making production line plastic lunch box machine

PS foam food container making production line plastic lunch box machine forming and cutting incorporated machine designed by our company is all-powerful. The main way is vacuum forming as well as press forming and synthetical forming.

It can be used for forming kinds of plastic sheet. This machine adopt PLC control, it has group possesses reliable stability, large forming area, high production and automatic degree.

The machine can mainly forming the PSP material which is used to produce food container, tray, bowl, cup etc. Forming, cutting, stacking are done in the same machine, saving labor,

improving efficient, lowing labor intensity and reducing production cost. Production process is to put foam sheet into forming machine, and product and wastage will come out from the rear part.

Other two types

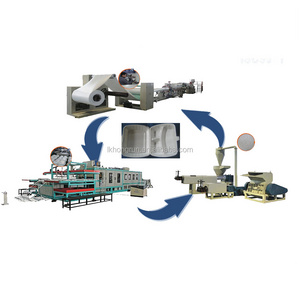

Disposable plastic foam dish making machine production line includes

3 PARTS

:

(1) PS foam sheet extrusion line:

make PS foam sheet from raw material

(2) Automatic Vacuum Forming and Cutting Integrated Machine

: make PS sheet to finished products, such as PS foam tray, PS foam box etc. (we can design mold according to customer requirements)

(3) PS Crushing and Recycling Machine:

recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again.

1. PS foam sheet extrusion line

High speed disposable PS foam take away food box making machine production line adopts double-screw foam sheet extrusion technology. PS foam sheet is a kind of new-type packing material with the features of heat preservation, safety, sanitation and good plasticity.

It’s mainly used to make various types of food containers, such as lunch box, dinner trays, bowls etc. by thermoforming. It’s also can be used to make advertisement board, industrial products packing and so on.

It has stable performance, big capacity, high automation and yields quality products.

| Model | HR-PSP70/90 | HR-PSP105/120 | HR-PSP120/150 | HR-PSP135/150 | HR-PSP150/200 |

| Screw Diameter | Φ70/90 | Φ105/120 | Φ120/150 | Φ135/150 | Φ150/200 |

| Foam Rate | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 | 1.0-3.0 |

| Width of Product (mm) | 640-1080 | 640-1080 | 640-1080 | 640-1200 | 1000-1350 |

| Thickness of Product (mm) | 1.0-3.0 | 1.0-3.5 | 2.0-3.5 | 2.0-5.0 | 2.0-5.0 |

| Output (kg/h) | 60-90 | 100-180 | 180-250 | 250-320 | 400-600 |

| Cutting Mode | Single Cutting | Double Cutting | |||

| Cooling Mode | Cooling by Wind and Water | ||||

| Mounted Power(kw) | 120 | 150 | 180 | 260 | 380 |

| Overall Size(m) | 22*4.0*2.8 | 24*4.1*2.8 | 26*4.2*3 | 28*4.2*3.2 | 30*5.2*3.2 |

| Total Weight (T) | 10 | 12 | 15 | 18 | 23 |

2. PS FOAM FOOD CONTAINER FORMING AND CUTTING MACHINE

Vacuum pressure forming polystyrene disposable food box making machine production line developed by combining the domestic and foreign equipment and advantanges,is a set of hydraulic pneumatic servo drive for an automatic forming punching machine.Vacuum pump,PLC,

the main electrical components,made in Japan and Germany,ensure the reliability of the equipment operation,and can be used for hot forming process many kinds of plastic amterial,it can product PS

packageing products,materials used in food,medical supplies,eletrical compoents,tourism products,toys,textile,and so on.

The biggest advantage is forming cutting integration,reduce work link,produce the product can be stacked directly collect,this will greatly seve time reduce the intensity of work and freatly saves labor.

| Model | Unit | HR-FCA750 | HR-FCA1100 | HR-FCA1250 | HR-FCA1400 |

| Max. forming area | mm | 750*1000 | 1000×1100 | 1000*1250 | 1000*1400 |

| Max. forming depth | mm | 80 | 80 | 80 | 80 |

| Production efficiency | s/die | 3~5 | 3~5 | 3~5 | 3~5 |

| Forming pressure | T | 12 | 15 | 18 | 20 |

| Mounted power | kw | 140 | 170 | 200 | 250 |

| Total weight | T | 14 | 16 | 18 | 20 |

| Installation size | m | 12*1.8*3.2 | 13×2×3.2 | 15*2.3*3.5 | 18*2.5*3.5 |

PS Recycling and pelletizing machine

It recycles waste products to granules, then can mix with new material put into ps foam sheet extruder with a certain proportion and mixed with raw material, using them as for finished product's material

| Model | HR-180+120/100 | |

| Screw diameter(mm) | Φ180+120/Φ100 | |

| Production efficiency (kg/h) | 80-130 | |

| Crusher motor power (kw) | 15 | |

| Main motor power (kw) | 29.5 | |

| Heating power (kw) | 35 | |

| Pressing material motor power(kw) | 1.5 | |

| Granulator (kw) | 2.2 | |

| Power supply | Three-phase 380v/50HZ | |

| Dimension size(mm) | 13000*3400*3000 | |

| Total weight (mt) | 3 | |

Food container/plate machine for China disposable plastic food container making machine

Q:Why I choose your company?

A: a, We are China Leading foam machine Manufacturer.

b, our company have made foam machine for many years with strong

experience and advanced technics

c, Best Quality & Best Service with Competitive price.

d, 100% inspection Before Shipment. And we have got CE certificate

e, we have Professional technical team, will supply 24 hours service

f, our machine have good quality, 1 year guarantee and lifetime maintenance

Q:What is the material of PS foam take away food container production line?

A:Polystyrene , Talcum powder, Butane, etc.

Q:What should we prepare except material

A:You should prepare workshop, water line, electric line, compress air(if you need I can help you buy air compressor)

We can supply workshop layout drawing.

Q: can you make machine upon our requirement?

A: of course, it is no problem, we can make machine according to your requirement, such as part brand, machine color, labels, moulds, etc.

Q: what is your parts brand?

A: The follow is our cooperative brand.