- Product Details

- {{item.text}}

Quick Details

-

Pump Number:

-

705-21-26180 705-21-26050

-

Usage:

-

oil

-

Structure:

-

gear

-

Product name:

-

Hydraulic Gear Pump

-

Material:

-

Aluminum Alloy

-

Certificate:

-

CE

-

Function:

-

boost

-

MOQ:

-

1PC

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wanxun

-

Application:

-

Wheel loader

-

Pump Number:

-

705-21-26180 705-21-26050

-

Usage:

-

oil

-

Structure:

-

gear

-

Product name:

-

Hydraulic Gear Pump

-

Material:

-

Aluminum Alloy

-

Certificate:

-

CE

-

Function:

-

boost

-

MOQ:

-

1PC

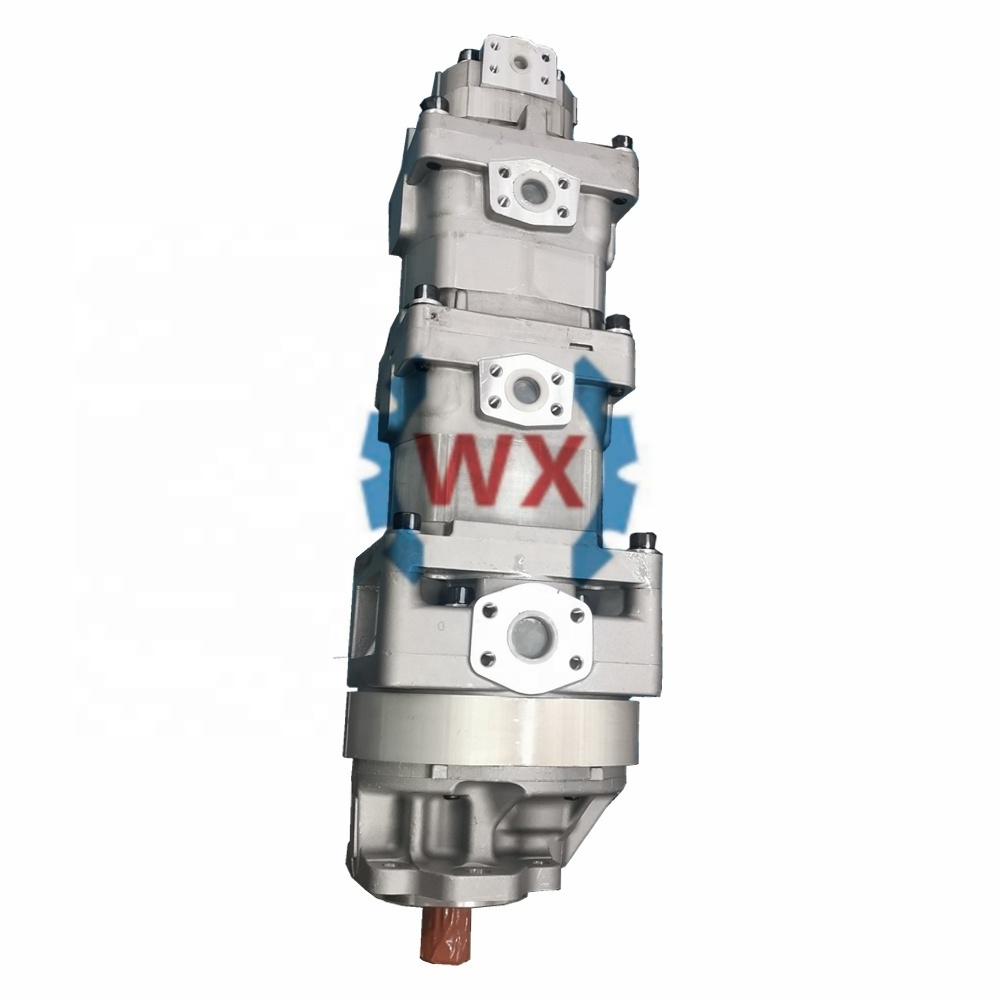

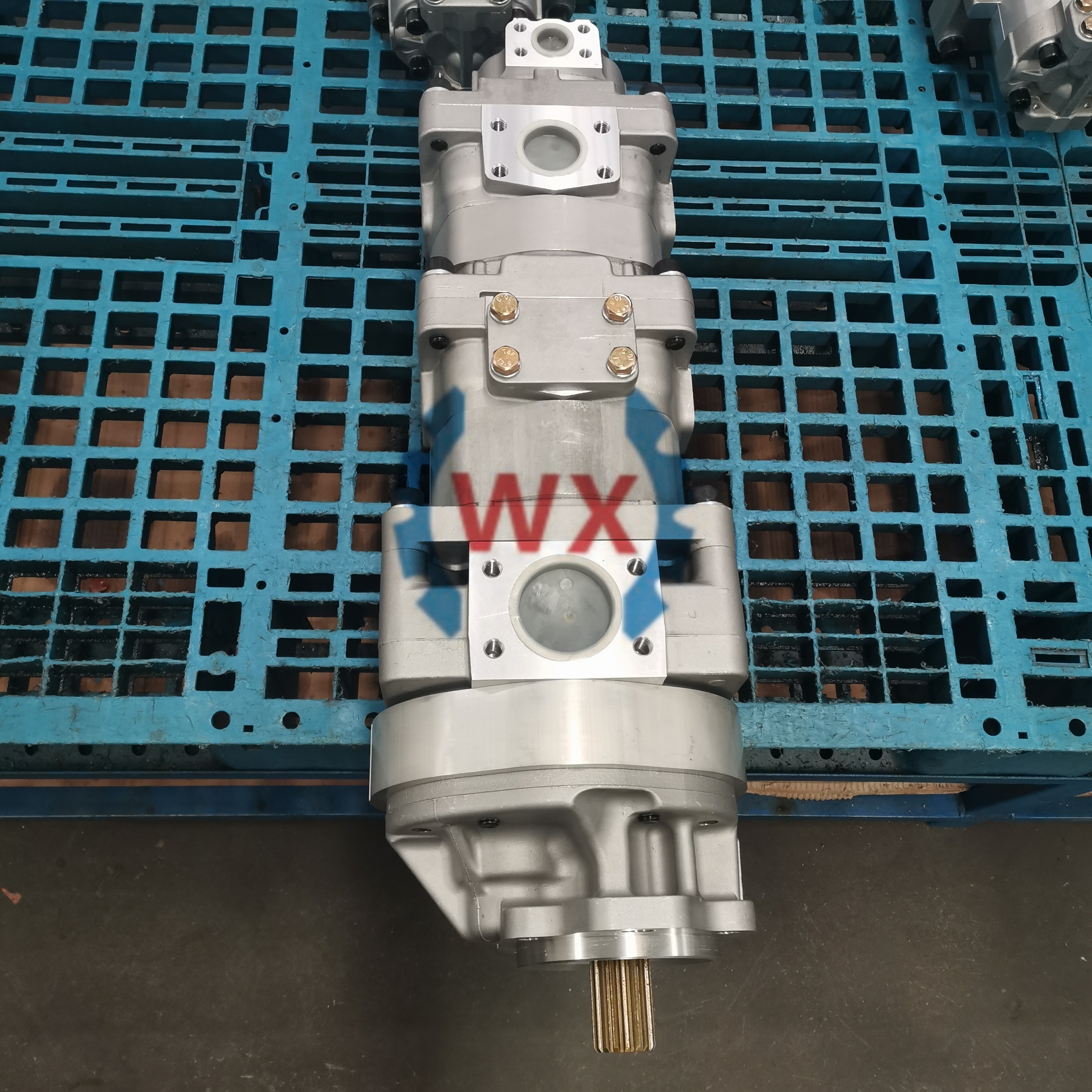

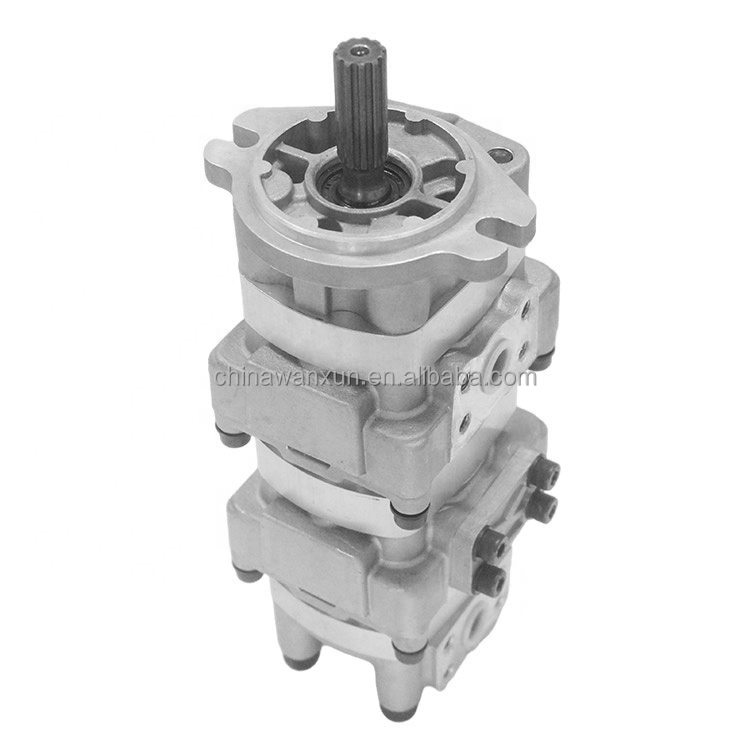

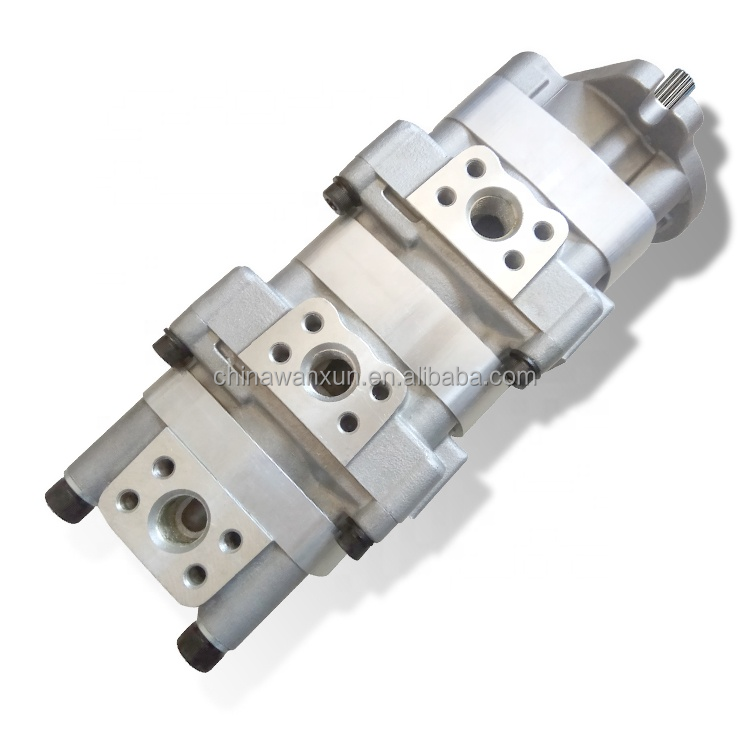

WA1250-7 705-21-26180 705-21-26050 Wheel Loader Excavator Dump Truck Bulldozer Crane Parts for Kawasaki Komatsu Gear Pump Spare

What is a gear pump?

A gear pump is a type of positive displacement (PD) pump. It moves a fluid by repeatedly enclosing a fixed volume using interlocking cogs or gears, transferring it mechanically using a cyclic pumping action. It delivers a smooth pulse-free flow proportional to the rotational speed of its gears. Gear pumps use the actions of rotating cogs or gears to transfer fluids. The rotating element develops a liquid seal with the pump casing and creates suction at the pump inlet. Fluid, drawn into the pump, is enclosed within the cavities of its rotating gears and transferred to the discharge. There are two basic designs of gear pump: external and internal gear pump.

What are the main features and benefits of a gear pump?

Gear pumps are compact and simple with a limited number of moving parts. They are unable to match the pressure generated by reciprocating pumps or the flow rates of centrifugal pumps but offer higher pressures and throughputs than vane or lobe pumps.

Gear pumps are particularly suited for pumping oils and other high viscosity fluids. Of the two designs, external gear pumps are capable of sustaining higher pressures (up to 3000 psi) and flow rates because of the more rigid shaft support and closer tolerances.

Internal gear pumps have better suction capabilities and are suited to high viscosity fluids, although they have a useful operating range from 1cP to over 1,000,000cP. Since output is directly proportional to rotational speed, gear pumps are commonly used for metering and blending operations. Gear pumps can be engineered to handle aggressive liquids. While they are commonly made from cast iron or stainless steel, new alloys and composites allow the pumps to handle corrosive liquids such as sulphuric acid, sodium hypochlorite, ferric chloride and sodium hydroxide.

External gear pumps can also be used in hydraulic power applications, typically in vehicles, lifting machinery and mobile plant equipment. Driving a gear pump in reverse, using oil pumped from elsewhere in a system (normally by a tandem pump in the engine), creates a hydraulic motor. This is particularly useful to provide power in areas where electrical equipment is bulky, costly or inconvenient. Tractors, for example, rely on engine-driven external gear pumps to power their services.

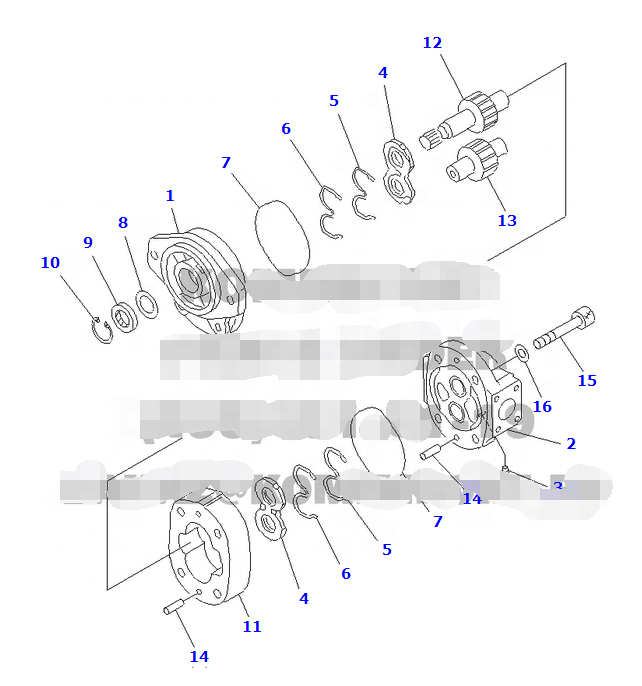

Basic design and structure of the external gear pumps for Construction Machinery:

External gear pumps, the most popular pumps used in modern hydraulics systems. These hydraulic gear pumps and motors can work under heavy duty operating conditions and transmit high hydraulic power, feature good hydraulic, mechanical and volumetric efficiency, low noise level and, last but not least, compact dimensions and low weight to power ratio. Ideal for both industrial and mobile industry sectors.

The basic components consist of a gear set supported by two aluminum bushings, a body, a securing flange and a cover. The shaft of the driving gear projecting beyond the flange mounts a seal ring coupled with a metallic ring to strengthen the setup. Both rings are held in place by an elastic securing ring. The body is made of a special aluminium alloy with high strength for minimized deformation even when subject to high pressure.

There are also cast iron bodied pumps and motors now available for applications requiring high pressures, optimal performance and endurance. Flange and cover are made out of cast iron or aluminium alloy, depending on the model series type, manufactured through a process of continuous flow casting and with a final surface treatment of phosphating.

Gears are made of special grade steel. Their manufacturing process includes case-hardening and quench hardening. The gears are ground and fine finished to achieve a high degree of surface finishing. Good tooth profile design and geometric proportions ensure low pulsation levels and low noise levels during motor operation.

Bushings are made of special low-friction and high-resistant aluminium alloy and manufactured from die-casting that have excellent high strength and anti-friction characteristics. Also equipped with anti-friction DU bearings with tight tolerance.

Special and symmetric compensation zones onto bushings, insulated by special preformed seals with special anti-extrusion ring, allow full free axial and radial movement to the bushings, which is proportional to motor operating pressure. In this way, internal leakage is dramatically reduced, ensuring very good pump performance (both in terms of mechanical and total efficiencies) and proper lubrication of pump moving parts.

Why buy Wanxun hydraulic gear pump?

Shaft sleeves are imported from DAIDO Japan.

Oil sealing is made by NOK Japan.

Hydraulic pump Case is an extrusion molding which is produced by extruding machine (press power is 7200 Ton ). Pls check pic as below:

Smooth surface, hard density of material.

Complete variety for international pump parts (more than 300 kinds of Hydraulic pumps)

Note before quotation:

For fast and accurate quotation information, we need more details:

1. Your specs model of construction Vehicle

2. The hydraulic pump part number (most important)

3. The photos of pump

4. The direction of rotation for the pump (anticlockwise or clockwise)

Installation and Operation Manual of the gear pump:

The Hydraulic Oil must be clean and fresh, the bad condition of Oil will damage and reduce working life of pump. Please add in HYD Oil in the pump before installation. It will affect working efficiency of pumps when the old pump and new pump connect. In developed industry market, the spare parts of gear pump achieved sophisticated. Therefore, check of clean oil with operation before using pump. The installation should be according to the ex-works technical documents of gear pump, and related specification of this manual, also the pump structure should be taken into consideration.

1) Before installation, please fill the inlet holes with enough clean hydraulic oil, please use new oil to ensure the oil quality is clean. Only when the oil is filled up, when the machine is started, a vacuum will be formed inside the pump body, so there will be pressure/power to vehicles.

2) Before installing the new pump, clean the filter element, oil pipe and oil tank to ensure that the hydraulic oil is sufficiently clean.

3) Please check whether the pressure control valve of the vehicle is stuck by long-term accumulated impurities, and clean it up in time. Otherwise, the valve needle will be insensitive, cannot open and close normally, and the pressure will be abnormal.

4) Run the vehicle at low speed for about 15 minutes, and then put it into work after everything is normal.

The Gear Pumps Maintenance Issues:

Gear pumps require good, robust installation, a PRV to protect the pump from overpressure and an assured supply of clean liquid. Those with outboard bearings require the bearings to be lubricated. Mechanical seals introduce there own set of problems and if possible select pumps that do not use them. If mechanical seals are fitted it becomes critical that shafts run true and the process pressures and flows are steady and do not fluctuate wildly to load up the bearings and gear teeth unevenly.

The gear teeth must not be run dry. Unlubricated teeth will rub together and wear away. If these pumps are run dry and temperatures rise the cogs will expand and start rubbing on the housing. This will tear-up the housing and teeth. Either the pump is destroyed or the fine housing clearances are lost which then allows recirculation within the pump. The best protection against dry running is to install a flow switch in the suction line that turns power off to the pump if there is no flow.

Application for komatsu/Shantui/Kawasaki/Caterpillar machine:

Wanxun Hydraulic Gear Pump Factory Show:

More than 30 years experience in gear pump design and research. Professional

specialized in hydraulic pump components of Komatsu construction Vehicle since 1983.

Our products include: Komatsu and Caterpillar Steering pumps, hydraulic pumps, gear pumps, work pumps, valves, crankshafts, frictions, PCBN, pistons, Shan Tui torques, bearings, cylinder sleeves, piston rings, motors, generators, filter elements, service kits, superchargers and fuel injectors. Our products are used in bulldozers, loaders, excavators, such as D80A-12, D85A-18, D150A-1, D155A-1, D155A-3, D355A-3, WA470, WA470-3, WA500-3, Shan Tui, Huang He TY130, TY160, TY180, TY220, TY230, TY320, SD13, SD16, SD22, SD42 and SD42-3.

Wanxun Hydraulic Gear Pump Workshop:

We care much on the quality control system in each step, from the raw material choosen, machine use, professional worker to make sure client get the best quality product!

Wanxun test system:

Each piece hydraulic gear pump is tested by worker to make sure each customer from the global get the rest assured product, we highly welcome you to test the sample!

Wanxun Hydraulic Gear Pump Series:

Our package warehouse, all the package is ready when you need the hydraulic gear pump, we can deliver it as fast as we could!

My factory take exibition around the world:

We are confident of our quality, and get approved and positive feedback from clients from the global!

Q1 Why choose our company product?

1.we have more than 30 yearss experience on gear pump design and research,Especially in hydraulic gear pump of komatsu contruction vehicles,

2.Owned-factory with competitive varieties

3.Quality and credit-reliable,complete varieties

4.Advanced imported manufacture equipment .construction machinery for Komatsu Japan and Caterpillar USA

Q2 HOW long is our delivery time ?

3-15 days after received payment or deposit

Q3 How to use the item?

1.if the previous pump of customers is ordinary wear and tear,such as busing abrasion,before installing a new pump,please repleace the engine oil,filter,and add fresh oil in the new pump.

2.If the previous pump of customers is not abraded as normal,such as scraping the Case inside,broken shafe,appears the iron dusts or theother condition,customers need to clean the oil tank before installing a new pump,

3.low speed working of engine for three minutes and then start to use as normal

Q4 What service we provide?

we have product customization service,quick shippment with 1 year warranty.

SOME HYDRAULIC GEAR PUMPS SHOWS AS BELOW:

705-51-32040 705-51-32000 705-51-31170 705-51-31150 705-51-31140 705-51-31060 705-51-30920 705-51-30820 705-51-30710 705-51-30660 705-51-30600 705-51-30590 705-51-30580 705-51-30360 705-51-30290 705-51-30240 705-51-30190 705-51-30170 705-51-30100 705-51-30010 705-51-22000 705-51-21040 705-51-21000 705-51-20930 705-51-20830 705-51-20800 705-51-20790 705-51-20640 705-51-20620 705-51-20480 705-51-20440 705-51-20430 705-51-20400 705-51-20390 705-51-20300 705-51-20290 705-51-20280 705-51-20240 705-51-20180 705-51-20170 705-51-20150 705-51-20140 (705-51-22000) 705-51-20110 705-51-20090 705-51-20070 705-51-12090 705-51-11020 705-51-10020 705-51-10010 705-41-08240(705-41-08260) 705-52-31070 705-52-31010 705-52-30A00 705-52-30960 705-52-30920 705-52-30580 705-52-30560 705-52-30550 705-52-30490 705-52-30390 705-52-30360 705-52-30290 705-52-30280 705-52-30260 705-52-30250 705-52-30240 705-52-30220 705-52-30190 705-52-30150 705-52-30130 705-52-30080 705-52-30051 705-52-30050 705-52-30040 705-52-30011 705-52-30010 705-52-22100 705-52-22000 705-52-21250 705-52-21170 705-52-21160 705-52-21140 705-52-21070 705-52-21000 705-52-20240 705-52-20160 705-52-20100 705-52-20090 705-52-20050 705-52-20010 705-52-10070 705-52-10050 705-52-10001 705-51-42080 705-51-42070 705-51-42060 705-51-42050 705-51-42010 705-51-32250 705-51-32080 705-11-36010 705-11-36000 705-11-35090 705-11-35010 705-11-34240 705-11-34110 705-11-34100 705-11-34060 705-11-34011 705-11-33530 705-11-33210 705-11-33100 705-11-33016 705-11-33015 705-11-33014 705-11-33013 705-11-33011 705-11-32540 705-11-32210 705-11-29010 705-11-28010 705-11-23010 705-11-22040